If you thought rapid prototyping was mostly relevant for developing consumer goods, seemingly miscellaneous valves, or even the occasional superbike and would never play a role in completely altering the way we manufacture energy on this planet, you’ll want to hear what they’re doing over at the International Thermonuclear Experimental Reactor (ITER) being built in St. Paul-lez-Durance, France.

Imagine planning out a one thousand ton, 60 foot stack of magnets and superconducting niobium-3-tin cables that will be a part of the plasma chamber for an enormous nuclear fusion reactor — something that will, hypothetically, produce 500 megawatts of output power. This is more energy than was necessary to cause the fusion reaction in the first place. In constructing such a device, potentially the first of its kind, you’d want to wrap your head around the blueprints in every way imaginable. And, while drawings and CAD models might give you some idea of how to construct the thing, 3D printing will bring your plans that much closer to reality. For that reason, the US ITER team at Oak Ridge National Laboratory is using the technology to aid in the preparation process.

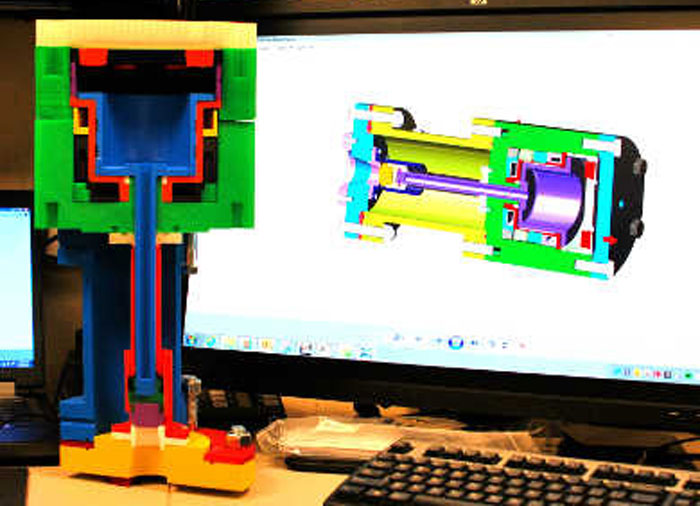

ITER engineer Kevin Freudenberg explains how 3D printing compares to other design tools for their project, “Now for pennies instead of tens of thousands of dollars, we can have impact right away with 3D printing. It lets us see what the part actually looks like. On 3D CAD displays, you can’t feel the shape of an object. You just see it. Many people have trouble seeing 3D projections or find them tiresome to view over time. With the 3D printed objects, you can run your finger over the surface and notice different things about the scale and interfaces of the component.” He adds, “We went to a vendor meeting recently. We looked at line drawings for a minute, and then the vendors spent hours looking at and discussing the 3D parts. Most of the meeting was spent talking about the parts. Having something in your hand that is tactile can show what machine processes and best practices to use in manufacturing.”

An engineer who is developing the reactor’s pellet injection and plasma disruption mitigation systems, Mark Lyttle, sees 3D printing as ultimately saving money in the design process, “It’s a lot more time consuming and expensive when you find that mistake in a metal prototype than it is in a 3D printed component. 3D printing is very low cost. With metal, you may have to start over if you can’t re-machine it.” He continues, “On the screen, some components don’t look especially bulky. But when you make it in metal, it will be a hunk of material that is too heavy and hard to handle. When you have a physical model, it is easier to spot opportunities to save material and make the design more efficient and the manufacturing less expensive.”

In the process of designing the reactor, the researchers are creating “toy” scale models of such things as the 60 foot tall central solenoid mentioned earlier. With smaller components, however, such as the fast gas valve for the reactor’s disruption mitigation system, they can be printed at one-to-one scale. Ultimately, Lyttle points out, they’re able to discover mechanical issues that may not have seen without 3D printing, “You can put it together, move it a bit and visualize how it’s going to be built. You can see problems like a weld you can’t get to or a screw head that is inaccessible.”

Nuclear fusion, the same process that produces energy from the Sun, is hypothesized to radically change the way we produce energy on Earth. After the National Ignition Facility in the US successfully demonstrated the small scale creation of a thermonuclear fusion reaction, the idea of using such a process on a commercial scale became a possibility in many minds. Because nuclear fusion requires very specific conditions to occur, it is thought to be environmentally safe. There is said to be no chance of a meltdown because any change in the reactor, such as a leak, would simply shut down the reaction automatically due to the natural forces of an unconducive environment. At the same time, there would be no greenhouse gasses emitted by a nuclear fusion reactor. Still, projects such as that of ITER are extremely expensive and difficult to pull off, meaning that we shouldn’t hold our breath, but, instead, should continue pursuing other green energy models in the meantime, until our utopian sci-fi fantasies are fulfilled.

Source: TechFragments