Are you wondering how you can use 3D printing to customize your sleek new Crocs? Or, maybe is there anything you can 3D print to make Mario Kart victory laps even sweeter? On a more serious note, what does forensic science hold for the future of 3D printing? And how is the technology helping search and rescue efforts? The 3D Printing Industry news digest, Sliced, has the answers.

Read on for a collection of all the latest news regarding medical innovations, creative applications and industry developments (Much more than just custom Crocs).

3D printing enables successful surgical procedure

In the medical industry this week, 3D printing has helped surgeons carry out a cardiac surgery. Frontier Lifeline Hospital has used 3D printing, mapping and modelling to digitally convert the pathological specimens of defects. This in turn enabled the necessary corrections to be made for a successful operation on 19-year-old Biochemical Engineering student at IIT BHU, Varanasi, Ria Sonigara. As an infant, Ria was diagnosed with DORV (double outlet right ventricle) with multiple defects in her ventricles and severe pulmonary hypertension. She was submitted for a cardiac surgery at Frontier Lifeline Hospital, India, where Dr. KM Cherian CEO and Chairman performed the procedure with the help of 3D modelling:

“A complete correction is what was contemplated for her and due to this it was necessary to have a 3D model of this complex defect. Made from high resolution 2D Echo and MRI, mending the two holes that she had in the heart and connecting the left ventricle to the aorta (the main pumping blood vessel), was achieved by intra-cardiac repair.”

Elsewhere Normanby Laboratory Services, a custom-made earpiece manufacturer, has invested in a new 3D printer. The company, co-owned by Diane and Paul Lincoln, manufactures hearing aids for the NHS supply chain across the UK, as well as hearing protection for uses like sporting and leisure under the brand name Plugzz. Since initially investing in its first 3D printer four years ago, the company has seen major benefits from the technology in cutting cost and time, and has therefore bought a second system to capitalize further on the advantages of the technology.

Developments in 3D printer filaments and bearings

Vesconite Bearings, a manufacturer of polymer bushings, has launched a new web store dedicated specifically to their selection of 3D printer bushings. Stock printer bushings start from $1.90 excluding taxes and shipping. The bushings come in two different grades developed by the bearings manufacturer: Vesconite Hilube and Vesconite Superlube. Both the grades help to reduce noise and ghosting, enabling better quality prints with self-lubricating properties.

Felfil, an Italian filament manufacturer based in Turin, has announced the release of the Felfil Spooler, which is designed to automatically wrap extruded filament around the spool at the convenience of the user. It has been developed to be utilized in tandem with the Felfil Evo, an open-source filament extruder from the company. Felfil say that it will help deliver better extrusion performance, and the company recommends the new device for all users 3D printing with ABS, PLA, and PETG.

Useful applications of 3D printing from bringing justice to helping search and rescue

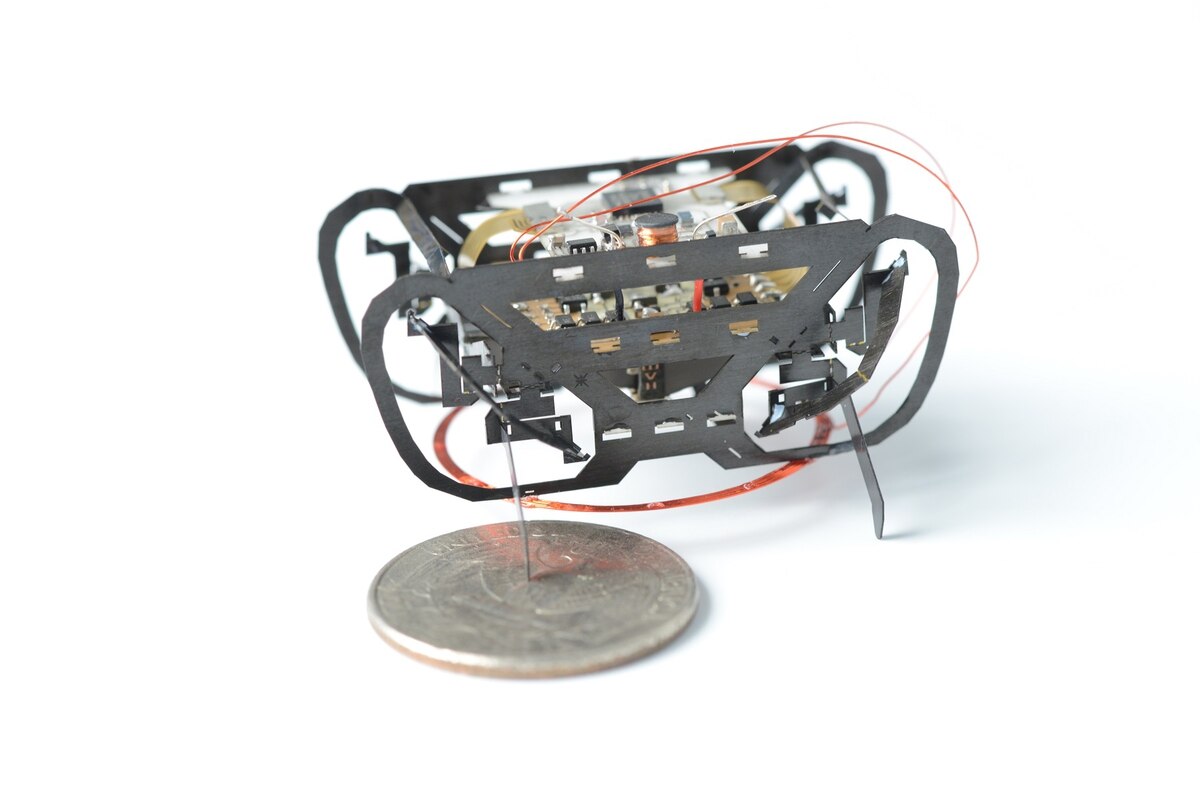

Using miniature 3D printed robots, future efforts in disaster relief and search and rescue could be made easier. Engineers from advanced technology solutions provider Draper, Harvard University’s Wyss Institute for Biologically Inspired Engineering and Paulson School of Engineering and Applied Sciences (SEAS) are using additive manufacturing to create a small climbing robot to help with search and rescue efforts. Created with funding from a recently awarded Defense Advanced Research Projects Agency (DARPA) grant, the microbots are designed to be one centimeter in size, and are capable of jumping and climbing up walls autonomously using built-in smart sensors.

“The size of our robots is expected to be quite small, in fact, insect scale, but we expect them to feature advanced technologies to enable them to navigate and accomplish complex tasks proficiently,” commented Nicholas Zervoglos, an embedded systems engineer at Draper. “The microrobots, as designed, should be capable of working in partnership with people for search and rescue, disaster relief, hazardous environment inspection, and other activities.”

If you thought that was small, Nanoscribe, a German specialist of nano-scale 3D printing, has provided a fly-over video demonstrating its microfabrication technology, seen below. The video contains a sequence of scanning electron microscope (SEM) images showcasing the intricate structures 3D printed with its precise Photonic Professional GT2 3D printer, which is capable of producing parts with print volumes of up to 100 cubic millimeters. A total of 18 objects with complex structures are presented in the video, altogether 3D printed in just over an hour, according to Nanoscribe.

3D printing is also helping to fight crime. A forensic center has been opened at the University of Warwick that makes use of digital scanning and 3D printing technologies to help support homicide investigations. With investment from the West Midlands Police, the Warwick Manufacturing Group (WMG) centre allows police to scan injuries on victims that are reportedly 1,000 times more detailed than hospital scans. They can also detect microscopic injuries which could otherwise be missed using conventional medical CT scanners. Using the scans, 3D renderings and prints are produced for use in testimonies and court trials, having already been used in over 100 homicide cases by 13 different police forces across the UK, including the death of nine-week-old baby Teri-Rae.

Another useful application of 3D printing sees the technology minimizing costs in the construction industry. Researchers from Nanyang Technological University (NTU) have used 3D printing to build prefabricated bathroom units in 12 hours. Potentially cutting half the cost of constructing the units with concrete casting (estimated to be S$6,000 to S$7,000), the bathroom’s also include fittings such as pipes and the toilet bowl. The 3D printed bathrooms are being put through stringent tests required by the Building and Construction Authority’s (BCA) Building Innovation Panel. This will help ensure that the bathroom meets the regulatory requirements in Singapore, making it suitable for implementation in Singapore’s high rise apartments.

Investments, acquisitions, partnerships and funding

Over to the business updates of the 3D printing industry and Polish 3D printer manufacturer Zortrax has reported a sales revenue of PLN 10 million ($2,650,300) for the first quarter of 2019, therefore generating a year-to-year increase of 71 percent from PLN 5.9 million ($1,563,677) in Q1 2018.

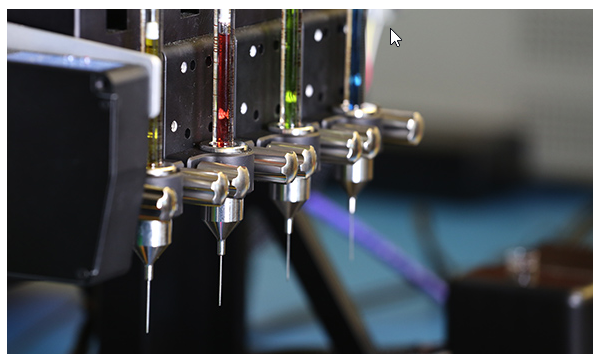

Sumitomo Mitsui Trust Holdings Inc., a Japanese trust bank group, has raised its stake in California-based 3D bioprinting company Organovo Holdings Inc by 14,093.5% in Q1 2019. This raised its ownership to 1.67% of Organovo, which was worth $1,980,000 at the end of the most recent reporting period. In February 2019, Organovo had said it expects to meet with the Food and Drug Administration (FDA) this year on its development of 3D bioprinted tissues for the treatment of liver diseases.

NextFlex, an American Flexible Hybrid Electronics (FHE) Manufacturing Institute, has made a call for proposals to fund projects aiding the development and adoption of FHE. This includes project proposals in the areas of ‘Additively Manufactured High Temperature Electronics for Hypersonics’ and ‘Demonstration of Inkjet Printing as a Path to Digital Manufacturing’. Titled Project Call 5.0 (PC 5.0), this is the fifth call for proposals that NextFlex has made, this time focusing on challenges related to scalable manufacturing and application-driven manufacturing gaps. The first four project calls resulted in over $73M in investment, and PC 5.0 is expected to generate over $10.5 million. Previous additive manufacturing beneficiaries of the NextFlex fund include Optomec for its Aerosol Jet technology and Lockheed Martin to create a database of additively manufactured antennas and microwave elements.

Laser Lines, a supplier of 3D printing technologies, has become the UK reseller for metal 3D printer manufacturer Xact Metal. Based in Oxfordshire, Laser Lines will be distributing Xact’s Metal’s XM200C and XM200S 3D printing systems, and the XM300C when it is released in 2020.

Mark Tyrtania, Sales Director at Laser Lines, commented: “We are delighted to be the chosen UK supplier for Xact Metal, whose metal printing systems are establishing new levels of price and performance.”

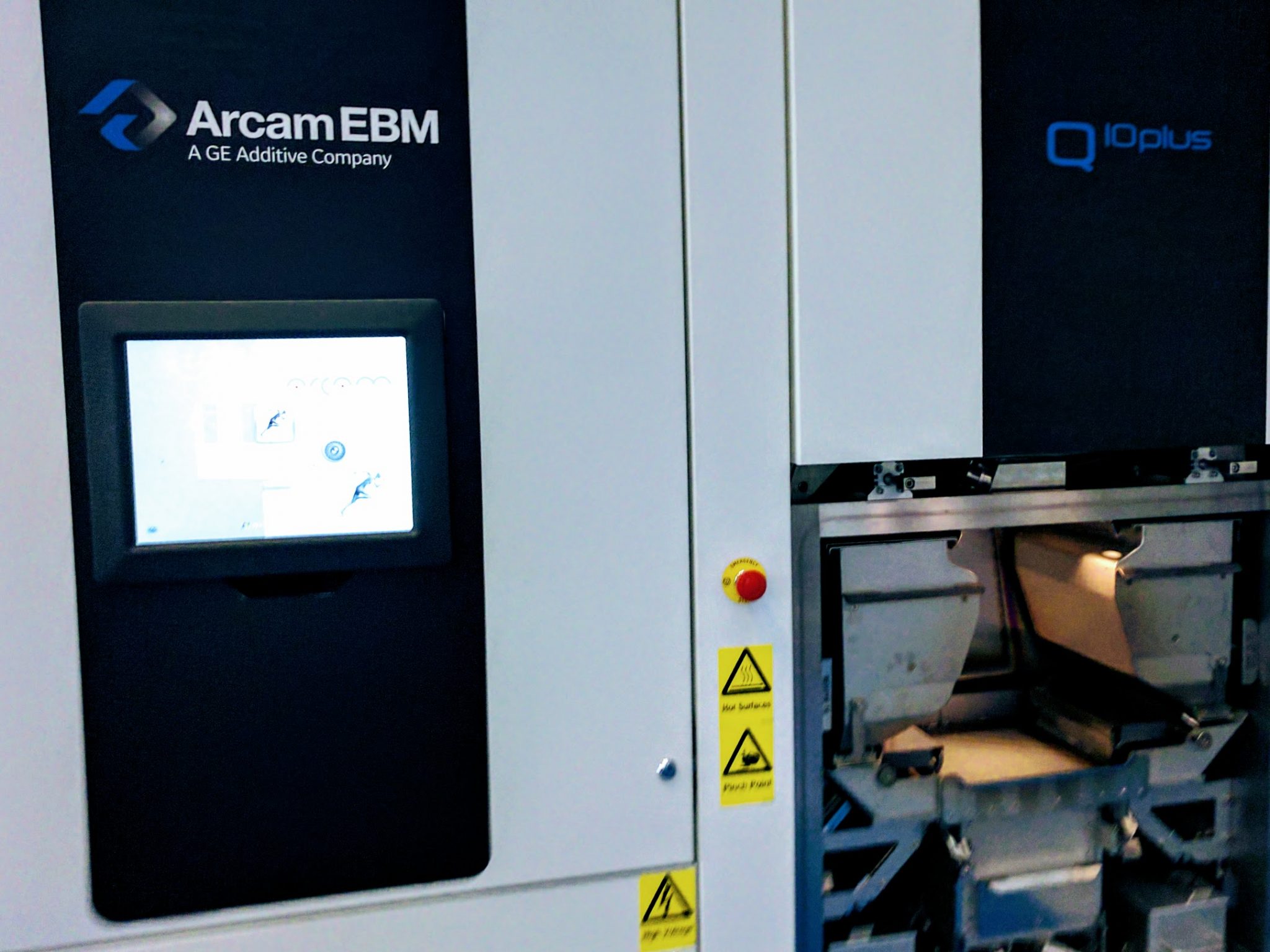

New Zealand-based titanium additive manufacturing company Zenith Tecnica has installed two new Arcam EBM Q10 plus systems from award winning OEM GE Additive. The additional 3D printers brings the company’s total selection of GE Additive Arcam EBM machines to five, alongside another Q10 plus system and two more Q20 plus 3D printers. Zenith Tecnica hopes its new acquisitions will help the company expand its capabilities in providing EBM services for a host of newly signed contracts with a leading medical implant provider in the United States, among others.

Schools use 3D printing to race into the future of manufacturing

This week sees a number of creative applications utilizing the design capabilities of 3D printing.

The planned 3D printed toy car race led by Ysgol Gynradd Nantgaredig primary school in Wales will be taking place from 11am at Carmarthen Park on Saturday June 22. The race is part of the Factory of the Future project from Swansea University, which aims to introduce children to smart manufacturing. Pupils from eight different Carmarthenshire schools have successfully assembled and painted their 3D printed cars using systems loaned from Swansea University, ready for the race. Each 3D printed car is based on a Daniel Norée design, who has experience designing and building 3D printed miniature F1 R/C cars. Following the race, participating schoolchildren will be asked to 3D print local landmarks.

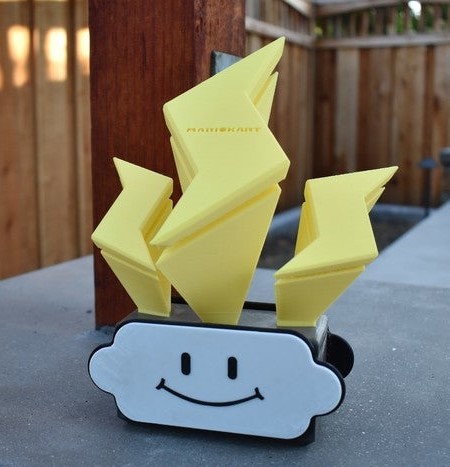

Hopefully avoiding any last-minute 3D printed blue shells, whoever wins the toy car race can perhaps 3D print themselves this Mario Kart 8 Deluxe trophy designed by artist Brent Werder. Based on the trophy for the lightning cup in-game, it took over 24 hours to 3D print all the parts. Furthermore, each part was sliced according to its colour, so as to avoid the need for painting anything, which meant swapping out multiple filaments. If you’d like to 3D print the trophy yourself, the files are available over at Thingiverse.

Italian architect Marcello Ziliani has used 3D printing technology from Italian 3D printer provider 3ntr to create a series of interior design pieces. Using the 3ntr A4 3D printer, Ziliani was able to prototype a lamp making use of the design freedom offered by 3D printing. This resulted in a uniquely designed lamp that went into production in 2017.

“By using 3D printing technology, we were able to build functional 1:1 scale prototypes that were presented to the customer and were used, in addition to the overall evaluation, to demonstrate the mounting system,” explained Ziliani.

“It was a product intended for the contract sector—in particular hotels—and it was essential that the assembly, installation, maintenance and cleaning phases were extremely simple. The fact of having used a natural transparent polymer also allowed us to evaluate the result in terms of quality and quantity of light.”

Crocs Inc, the company behind everyone’s favourite ergonomic, multi-holed plastic clog, has opened a three-month pop-up shop where customers can use 3D printing to personalize their pair of Crocs using an Ultimaker 3 3D printer. Located at Boxpark in Shoreditch, London, the store allows users to customize a pair of Crocs using 3D printed ‘Jibbitz Charms’ – small decorations that can be clipped to the ventilation holes in the shoes.

Two new conferences for AM

The American Society of Mechanical Engineers (ASME) will be hosting a new conference dedicated to additive manufacturing in the medical field. Titled AM Medical: Additive Manufacturing & 3D Innovations, the conference will take place at the Minneapolis Convention Center, Minneapolis, Minnesota, USA, from May 27–28, 2020. The event will showcase the latest advancements in additive manufacturing, materials, quality processes, scanning and visualisation. ASME organized the conference in collaboration with America Makes and Additive Manufacturing Media.

“There is an incredible demand for advanced healthcare solutions that impact patient care and operational efficiency,” stated Richard Laudenat, ASME President. “We are fueling collaborations that will unlock future growth opportunities and improvements for patient care.”

ASME is also taking part in the the 2019 International Advanced Manufacturing Research Conference, which will be hosted at Penn State Behrend from June 10 to 14 at Erie’s Bayfront Convention Center. The conference is a combination of two significant manufacturing events: the North American Manufacturing Research Conference (NAMRC) and the ASME International Manufacturing Science and Engineering Conference (MSEC). Advances in next-generation manufacturing innovations will be displayed at the event, including a presentation on the 3D printing of biological tissue.

“The workshops and presentations will plot out the next 10 years of research,” said Ihab Ragai, an assistant professor of engineering at Penn State Behrend and the conference’s organizer.

“We’ll see advanced processes, new designs and new ideas, and all of that innovation will be shared.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo edited on to an image of a Croc featuring customized Jibbitz charms designed by fashion company PizzaSlime. Original photo via PizzaSlime/Crocs.