Albuquerque additive manufacturing company Optomec has been awarded, alongside partners Lockheed Martin and GE, a $3 million NextFlex project dedicated to flexible hybrid electronics (FHE).

NextFlex is a U.S consortium of companies with the sole aim of creating FHE and ushering in a “new era” of the implements defined as “class of lightweight, low cost, flexible, stretchable, conformable and efficient devices for the Internet of Things (IoT), medical, robotics and communication markets.”

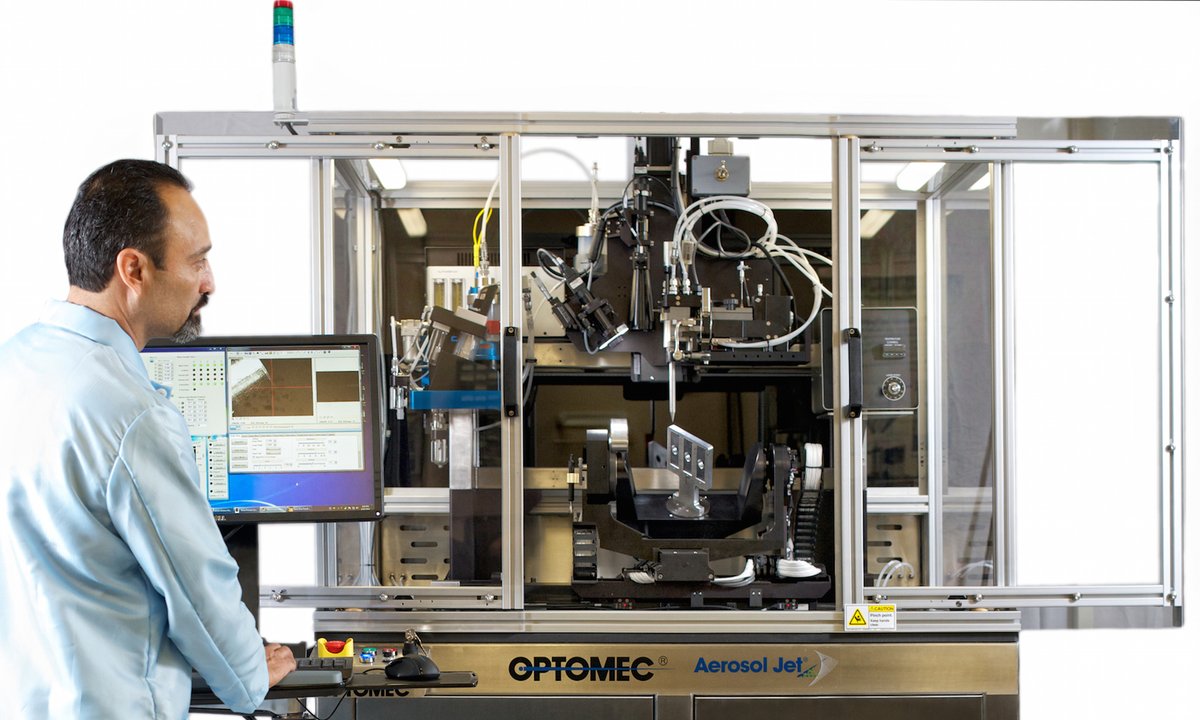

As part of the project, Optomec will provide 3D printers in the form of the Aerosol Jet 5x systems to the NextFlex Technology Hub in San Jose, California and in New York. By doing so, Optomec explains it will enable partners such as Lockheed Martin to “print conformal circuitry at resolutions down to 10 microns onto 3D surfaces.”

Printing onto complex 3D surfaces

The project, led by Lockheed Martin, is titled ‘Conformal Printing of Conductor and Dielectric Materials onto Complex 3D Surfaces.’ According to NextFlex, the project aim is to print “conductor and dielectric materials on complex 3D surfaces by advancing tooling, software and printing processes.”

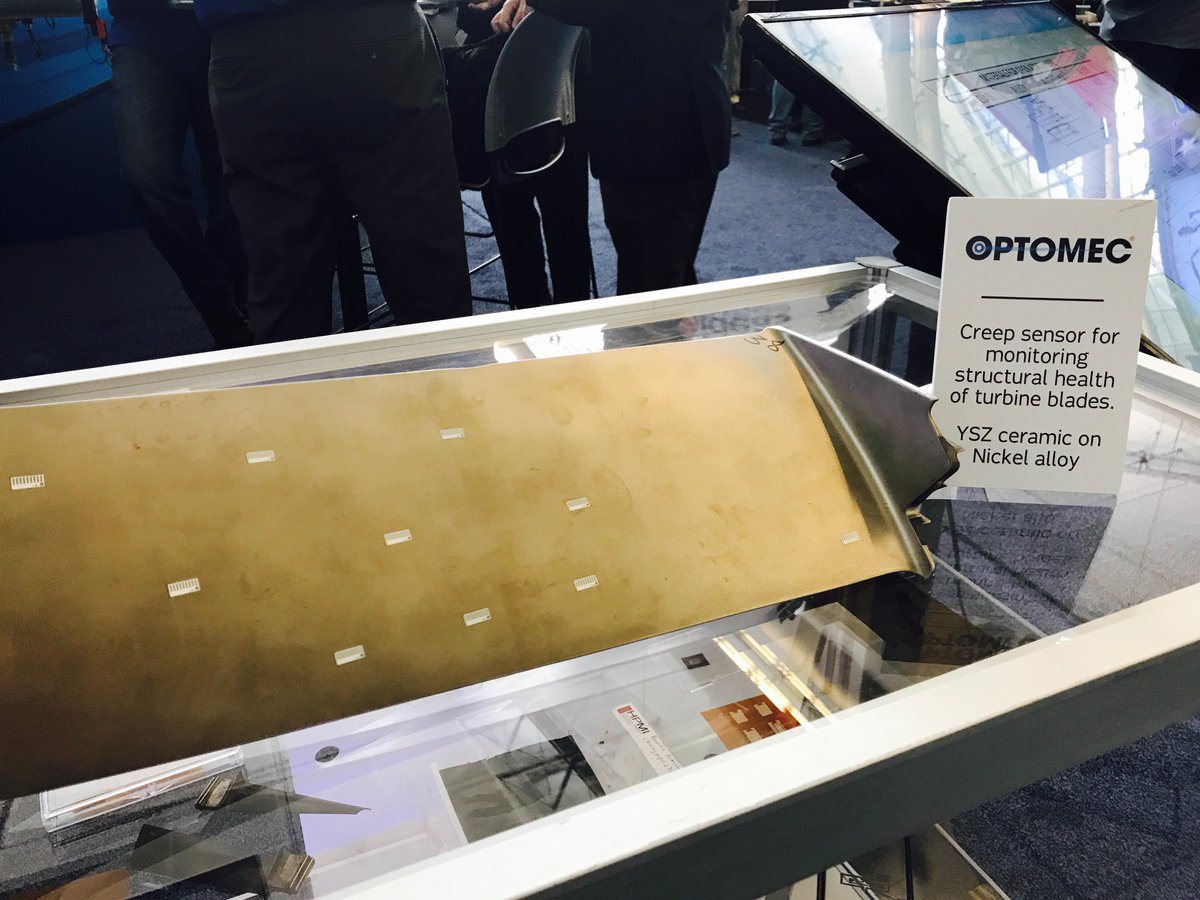

Optomec has already showcased, through its aerosol jet technology, the ability to 3D print electronic sensors onto a gas turbine blade for GE. Using a temperature resistant ceramic material, Optomec created a turbine blade that could detect deformities in its metal structure and potentially mitigate critical failure of the gas turbine.

Optomec CEO, Dave Ramahi, said with this project, the company “is committed to supporting industries’ growing need to deploy smart, connected devices that take advantage of data and cloud computing advances to improve performance and lower cost throughout the product life cycle.” In other recent developments of this technology, Optomec also announced a vital breakthrough in 3D printing conductive copper inks.

Applications of flexible hybrid electronics

In addition to 3D printing sensors onto parts such as gas turbine blades, the technology has a wide range of applications for electronics. FHE project lead Lockheed Martin has already applied 3D printing processes to its manufacturing capabilities, as the company recently 3D printed its first military satellite part. The aerospace and defense company has also expressed interest in using 3D printing to develop a future intercontinental ballistic missile.

Projects such as this one will hope to broaden the potential of manufacturing by utlizing 3D printed electronics to expand functionalities. As well as sensors, the project will also develop 3D antenna and other 3D devices.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows Optomec HQ in Albuquerque. Photo via Optomec.