A research team at Pohang University of Science and Technology (POSTECH) in Korea has developed a skin 3D bioprinting process to rival traditional means of cell culture. The POSTECH method cuts down on the cost of apparatus, and amount of live tissue needed to grow layers of human skin and demonstrates a substantial skin culture after 14 days.

The resulting cultures have the potential to be used in place of animal testing, and for human transplants.

Fabricating the largest organ in the human body

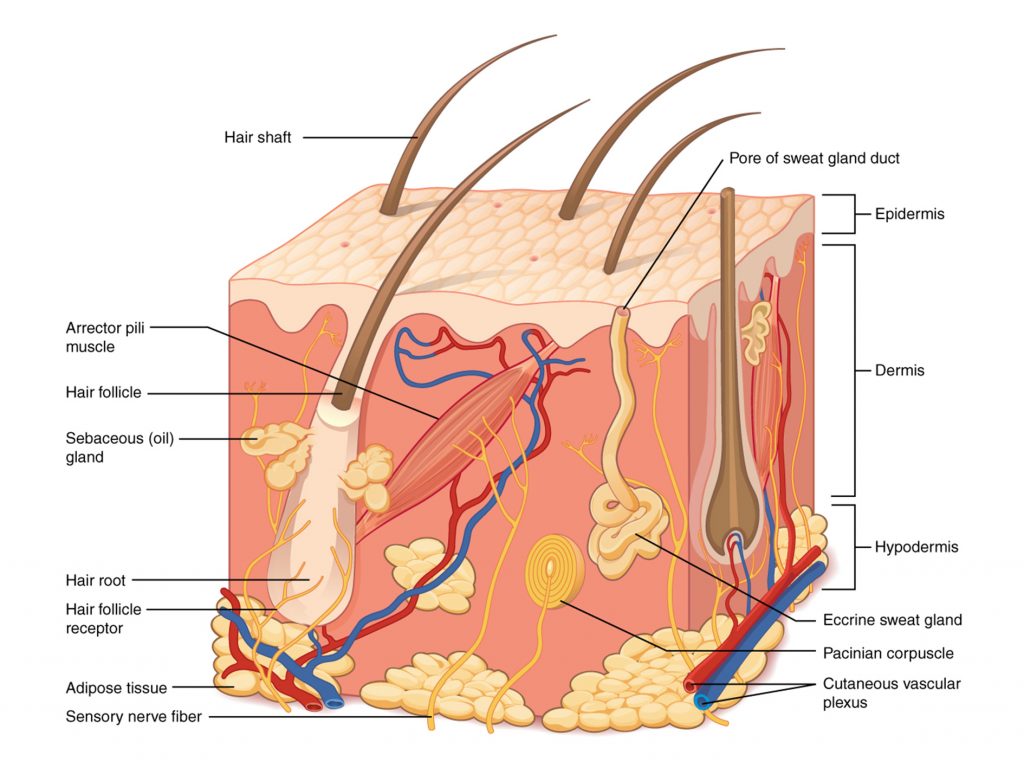

As the largest organ in the human body – and with a complex array of functions – skin is composed of three fundamental layers: the outer epidermis; the dermis containing hair follicles and sweat glands; and the fatty and connective hypodermis.

The variety and purpose of these layers is one of the key challenges to its replication in tissue engineering. And so artificial skin must be fabricated in steps in order to match its natural counterpart.

Step-by-step

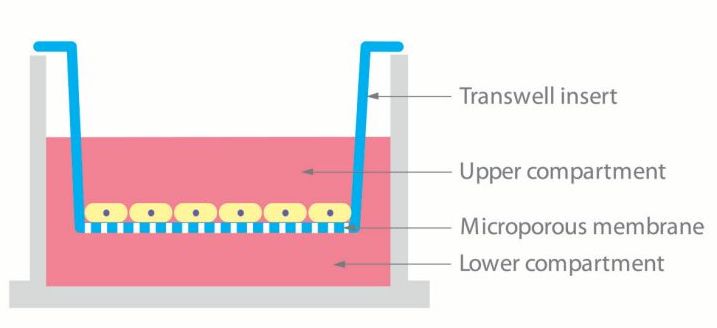

The method adopted by POSTECH is a development on an approach that uses transwell inserts to support the cells. Commercially available transwells are plates containing a number of small wells, sealed temporarily by a permeable membrane. When left to culture, the membrane allows cells in the bottom of the well to connect with material loaded on top of it.

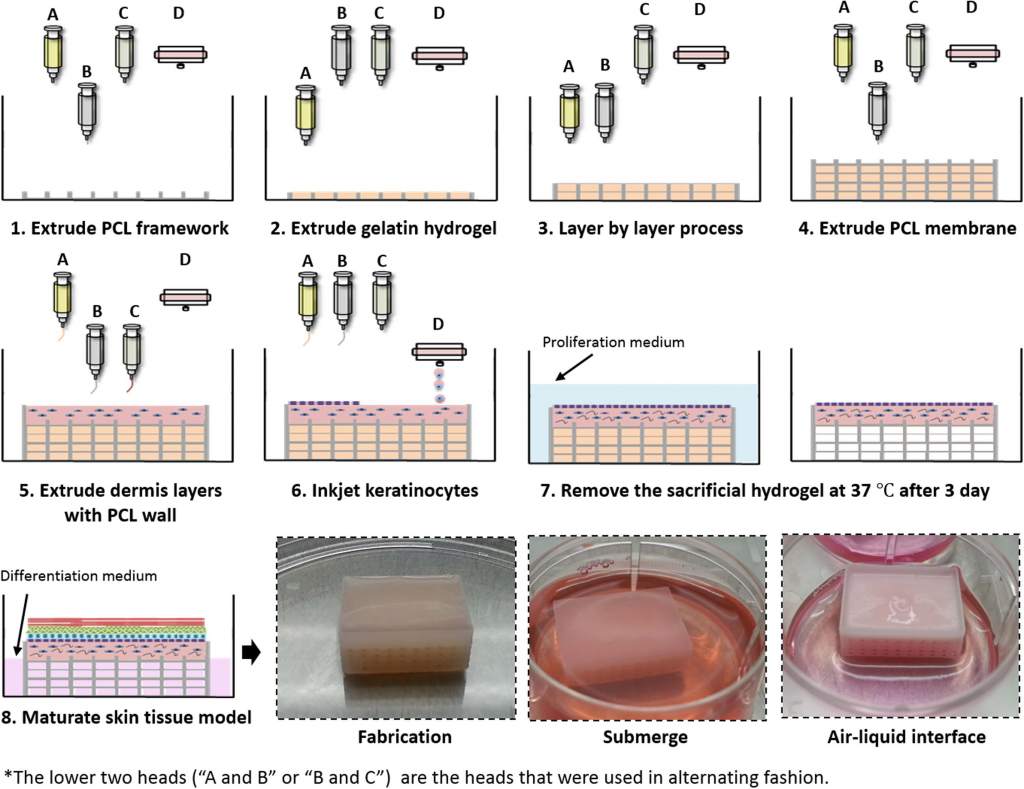

Instead of purchasing a commercial transwell, POSTECH researchers 3D printed the well-arrangement in PCL – a biodegradable polyester approved by the FDA. 3D printing of this supportive structure is done in stages as each ingredient is added to the skin composition.

An extrusion-inkjet hybrid

The POSTECH 3D printing process is a hybrid technique that utilizes both extrusion-based and inkjet means of 3D printing. It relies on the deployment of four printheads, arranged by the researchers in a custom-built 3D printer.

- Head A is an extrusion based head containing a sacrificial gelatin hydrogel which is removed before incubation.

- Head B contains the PCL polyester material used to 3D print a grid-like framework.

- Head C is a bioink containing collagen – the main structural protein found in skin.

- And Head D is the inkjet head that drops keratinocytes – the most predominant cell type in the skin’s epidermis, that functions to form a barrier against environmental damage to the skin.

Each of these heads is activated at different stages of the process to form a 3D sandwich of the materials, as seen in the diagram below.

After fabrication, the cell sandwich is submerged in a medium that promotes cell growth. The sacrificial hydrogel is also removed with washing, causing the subsequent layers to come in contact with each other and form connections. After submerging, the culture is exposed to the air to promote growth.

50 times cheaper with 10 times less material

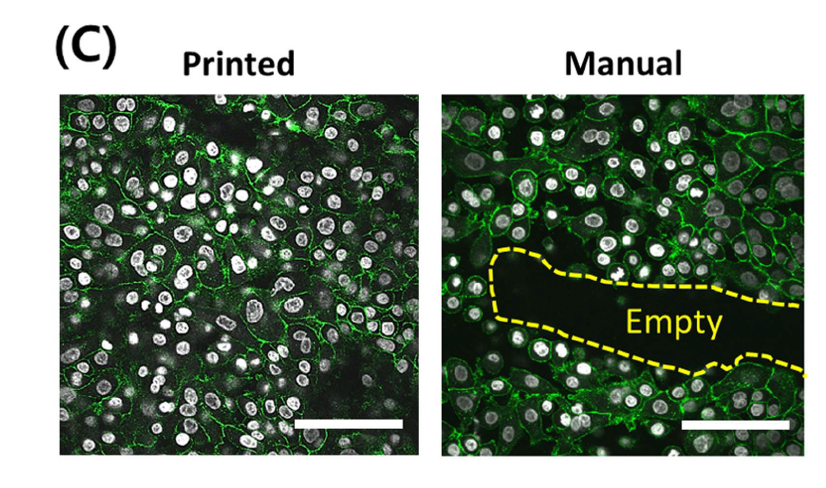

Alongside this approach, two other cells samples are prepared – one with manually-prepared PCL anchor (rather than a mesh) and another only with the collagen hydrogel as support. By comparison, the 3D bioprinted structure demonstrated less contraction after 7 days of culture, meaning that it is better at retaining its as-printed shape.

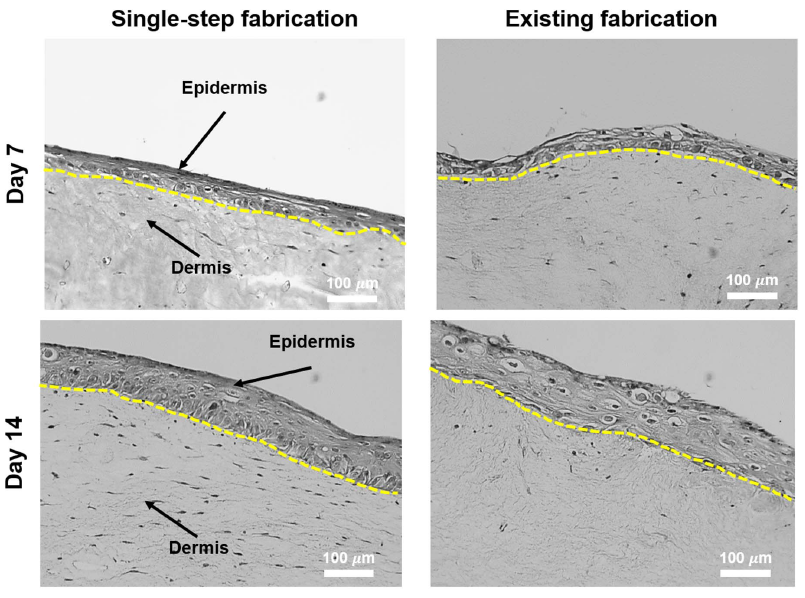

In further monitoring of the 3D bioprinted skin, the results researchers find that, “After 14 days at the air-liquid interface, fibroblasts” (cells found in connective tissue) “were stretched in the matured dermis, and the thickness of stratified epidermis remained in the range of native human epidermis. This observation suggests that our PCL construct, termed as a transwell system, enables the maturation of our skin model.

In conclusion the authors add,

This strategy was also cost-effective, with a 50 times reduction in cost and 10 times less medium being used compared with the conventional transwell culture. Because this novel strategy could open up chances for a simpler and more versatile design, our cell-printing system and strategy holds significant potential as a novel platform in engineering various human skin models as well as other tissue models.

Competition for the optimum regenerative skin

The Wake Forest Institute for Regenerative Medicine (WFIRM) in North Carolina is another school of research looking into the use of 3D printing for regenerative skin. In WFIRM’s approach, cells are 3D printed directly onto a patient’s wound to promote healing and rapid re-growth of the skin. This approach is particularly useful in the treatment of burns, and has been adopted for development by the U.S. Army. 3D bioprinting company Organovo are also in a skin tissue partnership, known as EPISKIN, with cosmetics company L’Oréal.

Direct 3D cell-printing of human skin with functional transwell system discussed in this article is published online in , Byoung Soo Kim, Jung-Seob Lee, Ge Gao and Dong-Woo Cho.

Stay up-to-date with the latest 3D printing research and news by subscribing to our newsletter and following us on twitter and Facebook.

Featured image: Structure of human skin. Diagram via Philschatz’s Anatomy-Book on GitHub