In this edition of Sliced, the 3D Printing Industry news digest, additive manufacturing enables the creation of the Bionic Girl, China reveals plans to build a solar power station in space with 3D printing technology and the longest 3D printed pedestrian bridge pays homage to ancient Chinese Architecture.

Also, the latest updates from Open Bionics, Desktop Metal, Tsinghua University’s School of Architecture, Sigma Labs, E3D Online, 3devo, and others are featured.

The Bionic Girl

Open Bionics, a UK manufacturer of 3D printed, bionic limbs for amputees, collaborated with Twentieth Century Fox Film, to create the 3D printed “Hero Arm” based on the new movie Alita: Battle Angel for 13-year-old Tilly Lockey. At 15 months old, Lockey lost both hands from meningitis B; now, with the Hero Arm Lockey can perform multi-grip functions as well as flex muscles just below her elbow.

The company secured a license agreement from Fox to style the Hero Arm users in the within the futuristic theme of the movie. Lockey, dubbed as the Bionic Girl, accompanied the film’s co-stars at the world premiere in London with her Hero Arms.

Professor Xu Weiguo and his team from Tsinghua University’s School of Architecture, behind the longest 3D printed pedestrian bridge installed in Shanghai last month, have divulged that the structure was inspired by the Anji Bridge. Also known as the Zhaozhou Bridge, the Anji Bridge is the oldest open-spandrel stone segmental arch bridge in the world.

New 3D printing materials

Desktop Metal, a Boston metal 3D printer manufacturer, has launched 316L stainless steel for its Studio System, an advanced in-house additive manufacturing system. This material is known for its corrosion resistance and excellent mechanical properties at extreme temperatures. Ric Fulop, CEO and co-founder of Desktop Metal said:

“The addition of 316L enables engineers to print metal parts for a wide range of applications, including engine parts, laboratory equipment, pulp and paper manufacturing, medical devices, chemical and petrochemical processing, kitchen appliances, jewelry and even cryogenic tools and equipment.”

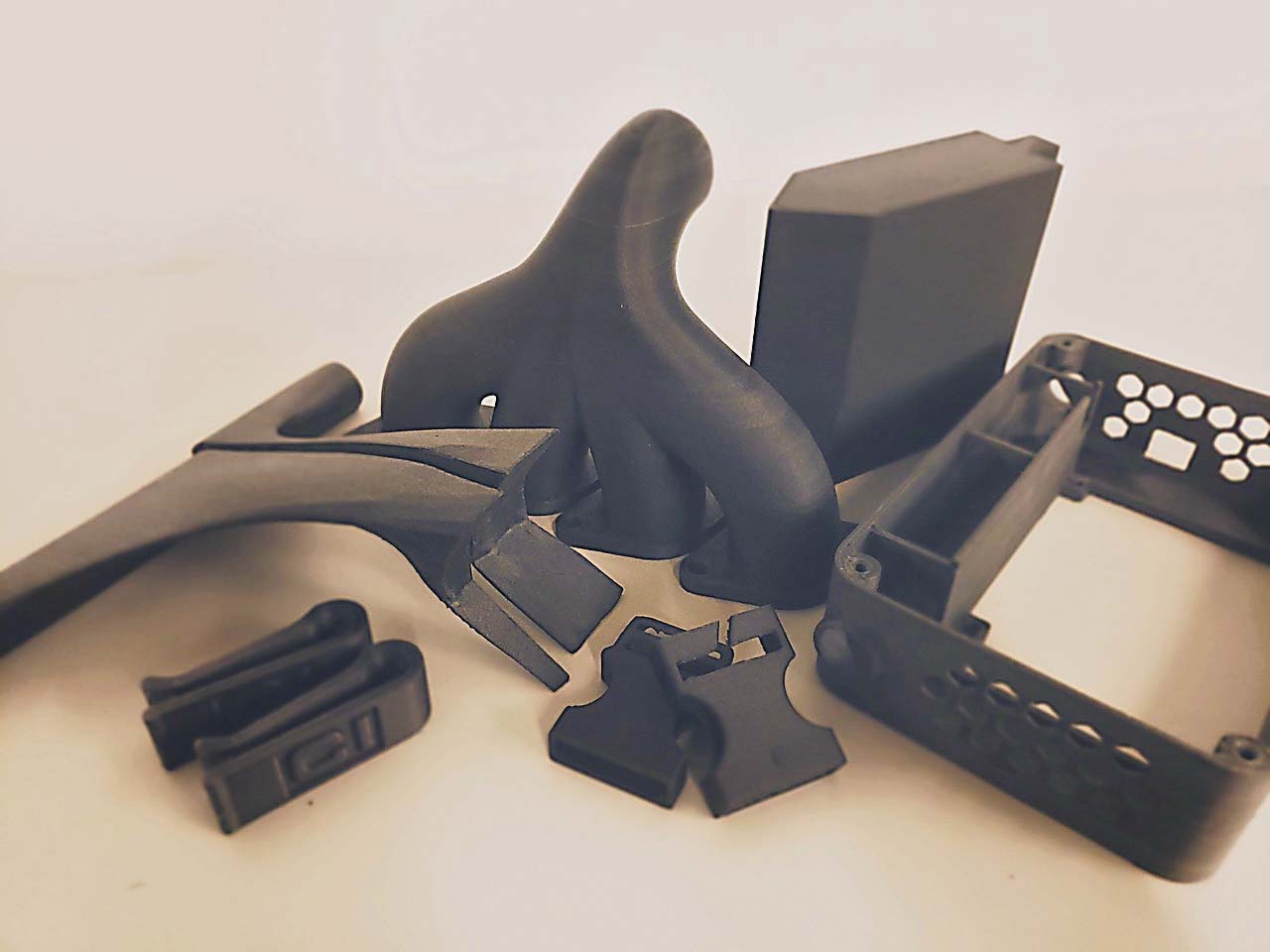

B9Creations, the South Dakota-based manufacturer of the B9 Core Series of DLP 3D Printers, has released its latest 3D printing material, Rugged – Nylon 6. Commencing the company’s engineering resin line, this material is said to be equivalent to injection-molded nylon.

Rugged-Nylon 6 is designed for functional testing and low- to mid-volume production runs; it demonstrates high impact strength and elongation, low moisture absorption, and is also low modulus.

Cincinnati Incorporated, an Ohio-based build-to-order machine tool manufacturer, has developed a new lightweight carbon-fiber resin material for its Small Area Additive Manufacturing (SAAM) FFF 3D printer. This material is said to produce parts with surface finishes suitable for custom tooling applications, as well as assembly, welding and, CNC fixtures.

Previously, Cincinnati Incorporated used its Big Area Additive Manufacturing (BAAM) technology to create the 3D printed vehicle called the Strati.

In other news, E3D Online, a UK-based manufacturer of 3D printer components, has addressed concerns regarding its latest nozzle, the NozzleX.

3D printing courses

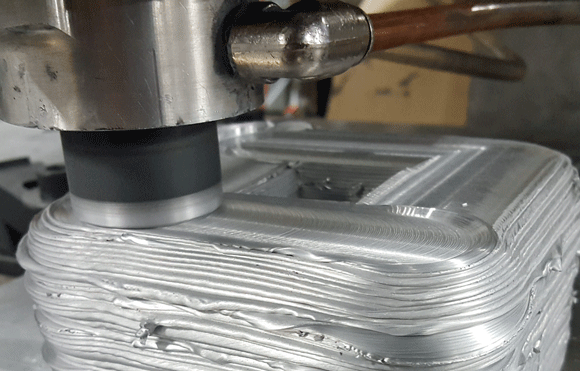

MELD Manufacturing, the metal 3D printing subsidiary of Aeroprobe, a measurement solutions provider, has launched a new training program to certify participants in operating MELD machinery. Within the 4-day course, both hands-on machine training and classroom instruction will be offered at technology MELD’s headquarters in Virginia.

The patented MELD solid-state process is designed to produce less residual stress than other melt pool metal 3D printing processes.

3devo, the Dutch manufacturer of the NEXT 1.0 Industrial Desktop Filament Extruder, has launched a series of hands-on training workshops on filament extrusion known as DevoTraining.

The DevoTraning workshops range from 4 hours to two days at the company’s headquarters in Utrecht and are focused towards manufacturers, innovators, researchers, and educators in the 3D printing industry.

3D printing at sea

The Charles de Gaulle, the flagship of the French Navy, otherwise known as the Marine Nationale, has onboarded a 3D printer for spare part production.

This is accompanied by an EOMS NG, an optronic naval system, and SMART-S and SCANTER 6002 radars which contribute to the operational efficiency of warships. Prior to this, a 3D printer was installed on the on the French helicopter carrier, the Dixmude.

Materialise, the award winning software and has reinforced its support for the UN Sustainable Developments Goals Charter at a round-table meeting, chaired by Her Majesty Queen Mathilde of Belgium. The company also received the ‘Factory of the Future Label 4.0’ from industry platforms Agoria and Sirris.

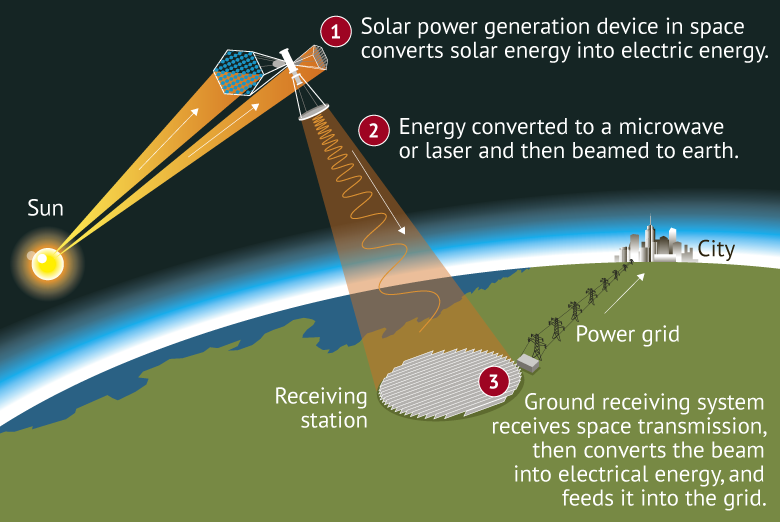

Similarly, researchers from the China Academy of Space Technology (CAST) are exploring the possibilities of building a solar power station in space to provide “an inexhaustible source of clean energy for humans”.

Pang Zhihao, a researcher at CAST has revealed that the team is examining the feasibility of using a space factory equipped with robots and 3D printing technology to construct the power station in space.

In other news, New York’s Space Exploration Architecture (SEArch+) a firm developing human-supporting design concepts for space exploration and Apis Cor, a Russian manufacturer of construction 3D printers has launched a Kickstarter for NASA’s 3D Printed Habitat Challenge.

SEArch+/Apis Cor will 3D print the Mars X House, a prototype of a future Mars habitat, in a live demonstration for NASA. The funds from Kickstarter will support tests on the structure before this demo.

Additive manufacturing and business

Sigma Labs, a Santa Fe-based 3D printing software and hardware company, has been named a member of the Additive Alliance of Fraunhofer IAPT – an international additive manufacturing network.

As the first U.S. company to join the Additive Alliance, Sigma Labs will seek to advance the development and implementation of additive manufacturing. This membership also further exposes the company’s PrintRite3D technology to the metal 3D printing market. Some of the Additive Alliance members include Stratasys, 3D Systems, Airbus, TRUMPF, and Renishaw.

Automated post-processing provider DyeMansion will distribute its Powershot C, Powershot S, and DM60 coloring system through the UK with Europac3D, a 3D technology hardware and service reseller.

In the healthcare sector, PrinterPrezz, a California-based 3D printing service bureau specializing in the medical sector, has signed a customer agreement with SI-BONE, a medical device company, to develop and build services for future 3D printed implants appliances.

Nominate for the 3D Printing Industry Awards 2019.

For the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Why not visit 3D Printing Jobs to commence your career in additive manufacturing?

Featured image shows the Sliced logo over Tilly Lockey with her 3D printed Hero Arms. Photo via Open Bionics.