Desktop Metal, a Massachusetts-based manufacturer of metal 3D printers, has launched the next generation of its Studio System, aptly named the Studio System+ which is capable of producing sintered voxels “as small as a grain of table salt.”

This advanced in-house metal 3D printer is accompanied with the launch of Studio Fleet, a system of three or more Studio System + printers, debinders, and furnaces designed to address challenges in low to mid volume production.

“While the initial Studio System meets the needs of many markets and use cases, those that specialize in small parts with intricate features/details, like metal injection molding (MIM), demand higher resolution to meet their requirements,” Lynda McKinney, Head of Global communications, told 3D Printing Industry.

The Studio System+

First introduced in 2017, the Studio System, which consists of a metal 3D printer, debinding station, and furnace, was designed as a safe solution for office-friendly metal additive manufacturing. Its patented layer technology (resembling FDM) extrudes bound metal rods as opposed to laser-based processes such as metal powder bed fusion, which can cause hazardous risks from fire and explosion to harmful powder inhalation and contact.

Furthermore, the Studio System also enables the use of closed-cell infill for lightweight strength, a function demonstrated by the MIT BattleBots team who used the system to fabricate cost-effective parts for its Sawblaze robot.

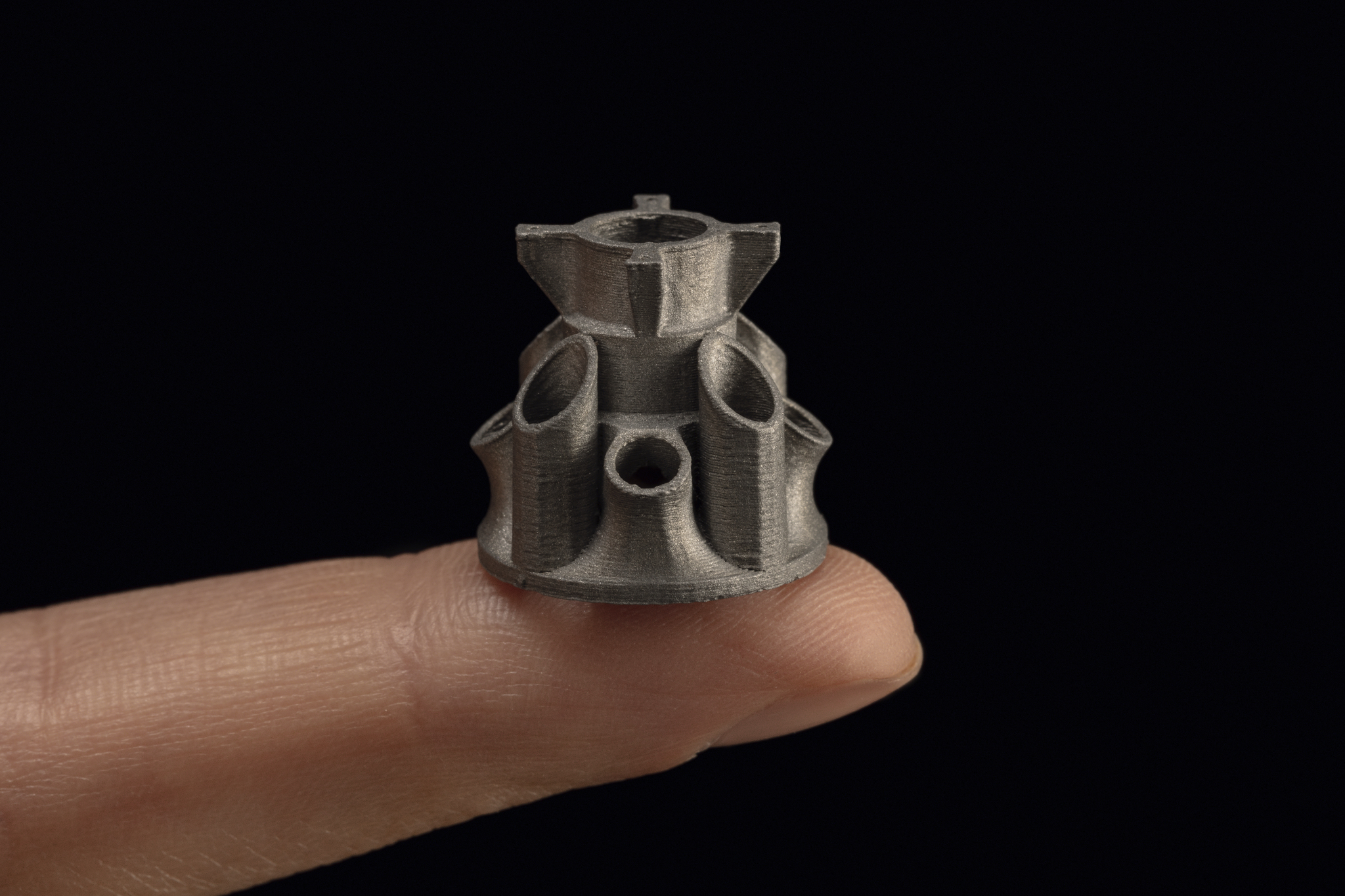

While the new Studio System+ maintains the key features of its predecessor, it also offers a swappable high-resolution printhead capable of sintering voxels as small as 240 microns in the XY axes and 45 microns in Z. The new system also has an in-chamber build plate camera for live print monitoring as well as a retort box design to increase thermal uniformity, resulting in higher quality parts. Furthermore, the system features new stackable shelves to maximize the part capacity of the debinder and furnace.

The Studio Fleet

The software improvements for the Studio System+ includes automatic mold lock prevention, part positioning and fleet management which configures the Studio Fleet. According to Mckinney, the mold lock prevention allows users to print certain geometries with separable supports. This eliminated the need for metal supports which must be cut off of a part.

“We are attracting a lot of customers who are new to 3D printing and we want to ensure that the software takes all of the guesswork out of the process and makes the customer as successful as possible with every part they print.

Leveraging the Studio System+ and its Fabricate cloud-based software, the Studio Fleet is capable of batch processing for rapid prototyping and tooling applications. Its two configurations include the 3:1:1 – three printers, one debinder, and one furnace, and the 5:2:1 – five printers, two debinders, and one furnace. The former is said to realize a 200% increase in throughput for a 50% increase in system cost whereas the latter offers a 400% increase and 100% increase in system cost. McKinney added:

“If you have demand for a lot of metal parts, which most machine shop/prototyping labs do, the Studio Fleet is the best configuration to handle the higher volume needs of these customer types. If they are looking for hundreds of thousands of parts per year, the Production System is a better fit. Studio Fleet helps fill this middle zone.”

The Studio System is priced at $60,000 or $160,000 with debinding and sintering hardware. It commences U.S. shipments next month. The Studio Fleet will begin shipments from the second half of 2019 and its hardware configurations are priced at $235,000 (3:1:1) and $315,000 (5:2:1).

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter and follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows a complex metal part the size of a fingertip 3D printed on the Studio System+. Photo via Desktop Metal.