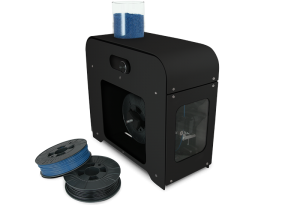

Dutch firm 3devo has just launched a couple of filament extruders, joining a growing market that allows users to create their own 3D printing material from ground plastics. On one hand they offer the 3devo NEXT 1.0, targeted mainly at makers, enthusiasts, 3D printing shops and schools. On the other hand they present the 3devo Advanced, developed for extrusion companies, researchers, plastics companies, universities and 3D printing companies. Both of their machines claim to bring industrial level performance and reliability to the desktop.

There are few key differences between the NEXT and the Advanced models; while the former has 3 heating zones which can reach temperatures of 350°, the latter has 4 of these and can reach 450°, which allows this model to extrude materials such as PEEK and other engineering grade plastics. Furthermore, the Advanced model has a mixing section built into the extruder screw.

Extruding your own filaments

Extruding plastic allows users to recycle not only 3D prints, unused 3D prints, misprints or old filaments but also other plastic goods that are readily available, which can allow to creation of interesting material combinations. According to the company extruding filament is a key part of the movement to recycle. However, this market is still in its early stages and whether this becomes an attractive value proposition remains to be seen.

According to 3devo, recycling and using virgin pellets can also help lower the cost of 3D printing by a factor of 7.

Inside the box

Both the 3devo NEXT and Advanced are stand alone devices which feature:

- Self-regulating filament diameter control system which lets you set the desired diameter and ensures for consistent output of the extruded filament.

- Up to 0.7 Kg of extruded material per hour.

- Diameter sensor with 43 Micron accuracy.

- Hardened Nitrite steel extruder screw with compression zone.

- High precision RPM encoder feedback.

- Automated motor control.

- Extrusion diameter that can be set between: 0,5 – 3,0 MM

- Hoppers with Built-in material level sensor which lower the risk of ‘dry running’.

- Powerful cooling system for high speed extrusions.

- Automatic spool winding.

- An easy to use spool mount that can variably set for different spools.

- Easy to use interface.

- Presets to handle ABS and PLA.

- Let you set and define your own preset materials settings as well.

- Manual temperatures and speeds controls.

- Custom presets creation.

- Both systems measure: 506 L X 216 W X 540 H MM [19.9 X 8.5 X 21.3 IN]

Both models are available at their website, the NEXT costing €3,100 while the Advanced offers to variants: €3,950 (for the black powder coated) and €4,150 (for the anodized version).

Tell the 3DPI community about your experiences or thoughts about extruding your own filament in the comment section below.