Interested in reading more about the year’s biggest 3D printing news? You can access our full 3D Printing Industry Review of the Year series here.

Heading into the second half of 2022, the 3D printing industry saw a surge in aviation applications. 3D Printing Industry visited the Farnborough International Airshow, to see several of these AM for aerospace applications and we reported on others developed via government-backed defense contracts.

Elsewhere, market consolidation continued, while VC firms continued to pour hundreds of millions of dollars into additive manufacturing.

Read on for the standout developments in July, including those of GE, GKN Aerospace, AM Ventures, Stratasys, Nano Dimension, Markforged, Digital Metal, AML3D, T&R Biofab, nTopology, the Royal Air Force and more.

Aviation AM takes off at Farnborough

Many of the year’s most innovative aerospace 3D printing applications were on show at Farnborough, and 3D Printing Industry was in attendance to cover all the latest developments. Skyrora, MELD, Boom Supersonic, and GKN Aerospace provided updates on their respective 3D printing projects, with the latter revealing that it’s working on enhanced DED data acquisition and control systems.

In July, the release of GE’s Q2 2022 financials also revealed that its revenue had been boosted by selling over 200 3D printing-enabled CFM International LEAP-1B engines to major clients like Delta Air Lines and Qatar Airways. As the year wore on, 3D Printing Industry was invited to get a sense of GE’s future 3D printing plans in person through a tour of its facilities in Cincinnati, Ohio.

During the tour, it was revealed that GE’s ATC had expanded its pool of metals from three to six, including cobalt chrome and nickel alloy 718, alongside two pairs of aluminum and titanium alloys. Some of the development work GE Aerospace is doing for the US Army was also covered, including its plans for the GE T901 engine, a propulsion system being designed to replace the Army’s current GE T700s.

In another defense application, it was announced that the Royal Air Force was developing a drone attack unit composed of 3D printed UAVs fitted with munitions for destroying strategic targets. Having scrapped its previous ‘Mosquito’ drone-building program, it was said that the RAF had switched its focus to creating a fleet that could be deployed with greater urgency.

Funding, consolidation and poison pills

July was a significant month in the 3D printing business world, with several major moves. Markforged acquired Digital Metal, in a deal that saw it expand into binder jetting for the first time.

This month, in a very different move, Stratasys made a poison pill filing, after Nano Dimension bought 12.12% of the firm. Filed with the US Securities and Exchange Commission (SEC), the company’s shareholder Rights Plan was essentially introduced as a way of discouraging Nano Dimension from attempting a hostile takeover.

On the funding front, AM Ventures closed its €100 million VC fund for promising 3D printing start-ups, while VulcanForms announced reaching funding of $355 million, the capital supports the opening of its first two digital production facilities, both of which are powered by its proprietary 100kW class laser powder bed fusion (LPBF) systems. One facility is focused on precision machining.

Generative design takes a step forwards

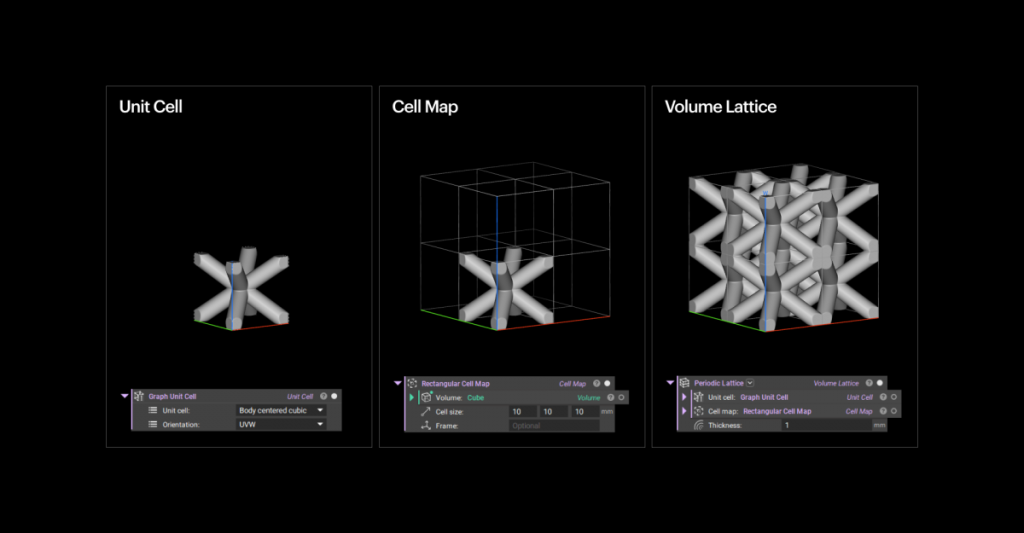

Already one of the leading software developers in the industry, nTopology took things a step further with upgrades to its topology optimization platform in July. Alongside the launch of nTopology’s third-generation latticing technology, it was revealed that the firm was developing several other design tools, such as field-driven lattice optimization capabilities and custom graph unit cells.

Trevor Laughlin, VP of Product at nTopology, said: “We are excited to release the latest generation of our lattice technology, which will continue to fundamentally change how engineers approach design for additive manufacturing. This new technology will enable industry-first advancements such as field-driven optimization, where the software automatically designs lattice structures for user-defined objectives and constraints. Ultimately, this will allow our customers to more effectively make use of the AM design space, resulting in innovative applications faster than ever before.”

July 2022: a big month for artificial skin

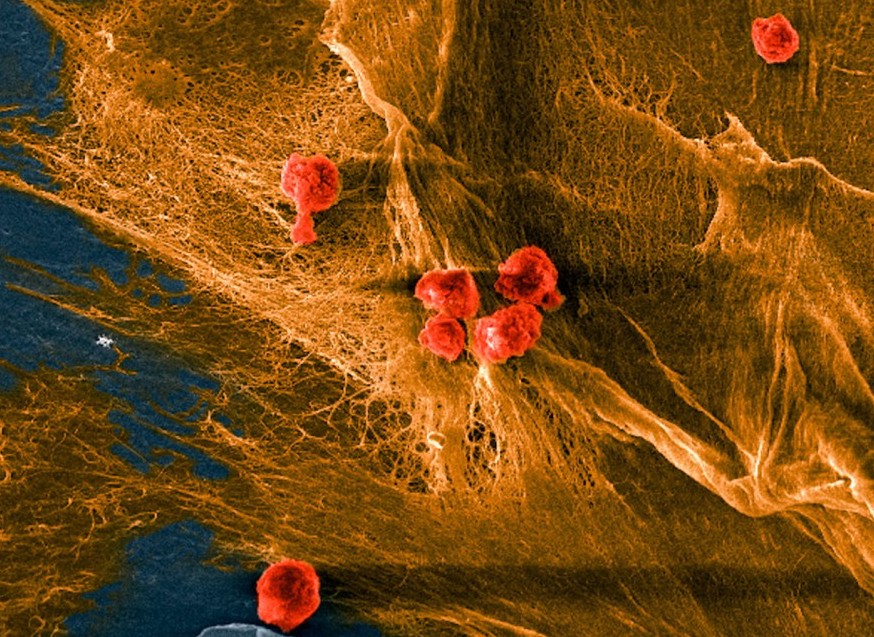

One of the more surprising trends to emerge in July, was the sheer number of artificial skin 3D printing projects announced. While researchers at Cornell University came up with a biomaterial that can be 3D printed into tissues, a team of Italian scientists developed a 3D printed artificial skin for robots, designed to improve their sensing capabilities.

Similarly, in the 3D bioprinting field, T&R Biofab patented a tissue-printing technology that was said to have the potential to treat heart disease without requiring open surgery. As of July, the process had already proven capable of creating 100-micrometer cardiac spheroids that effectively regenerated damaged tissues upon transplantation.

A team at the University of California, Berkeley, also unveiled a 3D Cryoprinting technology that could allow for the production of tissues with improved viability. Unlike other bioprinted tissues, which can be too soft to support their own weight, the scientists’ technology sees bio-inks frozen and cross-linked. This allows for the creation of cell structures capable of retaining the desired shape.

Harder, better, faster, stronger… larger?

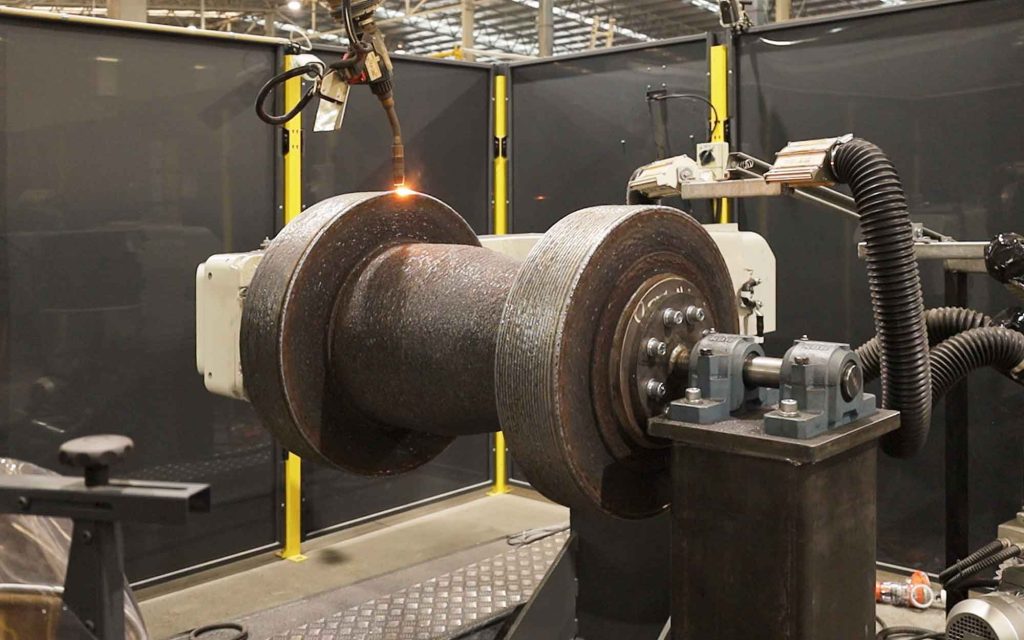

Lastly, 3D printing has long been on a trajectory towards the development of larger systems capable of producing bigger and bigger parts, and this was evident in July as well. During the month, AML3D 3D printed an eight-tonne pressure vessel for ExxonMobil. Utilizing its in-house Wire Arc Manufacturing (WAM) facilities, the firm reduced the part’s lead time from 12 months to 12 weeks.

The order, worth $190,000, further demonstrates 3D printing’s potential in oil and gas.

“Signing this deal with ExxonMobil is a further demonstration of delivery against our multi-phase growth strategy,” said Andrew Sales, MD of AML3D. “We have a major focus on building our capability and presence in the global oil and gas sector as an immediate value driver for the business, and this contract absolutely aligns with that objective.”

2022: 3D Printing Industry review of trends and news

2021: 3D Printing Industry review of trends and news

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an F-16C fighter jet on display at the Farnborough International Airshow. Photo by Paul Hanaphy.