Engineering software developer nTopology has introduced its third-generation latticing technology to allow users to unlock an even broader range of 3D printing applications.

Designed to be easy and quick to use, the new lattice design tools aim to provide users with greater control over complex lattice structures. The release includes 37 blocks that have been in development for the past 22 months, each engineered to make it faster and more intuitive for new users to learn how to apply advanced latticing and DfAM techniques and to streamline the lattice generation process for existing users.

The new latticing technology also lays the groundwork for further upcoming optimization tools currently in development at nTopology, that the firm says will enable users to “unleash future innovations.”

nTopology’s generative design platform

Founded in 2015, nTopology aims to enable engineers and designers to create any complex 3D geometry in order to meet the demands of high-performance applications. Customers making use of the firm’s software for their additive manufacturing operations include well-known names such as car manufacturer Ford, defense contractor Lockheed Martin, and manufacturing conglomerate Honeywell.

nTopology has continued to develop its nTop generative design platform since commercializing the software in 2019, raising $40 million in 2020 and a further $65 million towards the end of 2021 to expand the platform into new types of applications. As a result, the firm has since launched the FDM Assembly Fixture Generator in partnership with 3D printer manufacturer Stratasys, a tool designed to streamline the DfAM process for jigs, fixtures, and other tooling, and a new Masking Fixture Module designed to remove bottlenecks during the DfAM process.

Last year, the firm introduced GPU acceleration capabilities to its platform with the launch of nTopology 3.0, which reduces the visualization time of highly complex structures from minutes to seconds.

New latticing technology

Over the course of the last two years, nTopology has been working to perfect the capabilities of its new latticing technology release and implement feedback from its customers and community. The main aim is to make it as easy as possible for new users of the firm’s nTop platform to access the new latticing tools as soon as they start using the software.

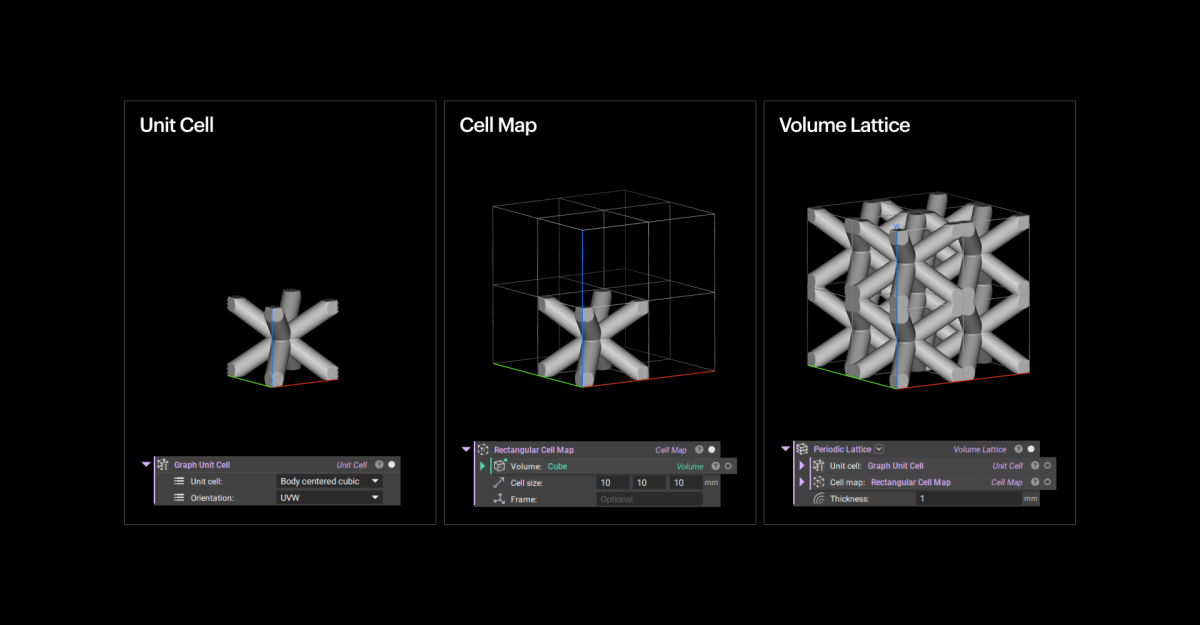

To achieve this, nTopology separated the lattice generation processes into three fundamental steps: select a unit cell, define the cell map, and control lattice parameters. By mastering these simple steps, users will find it faster and more intuitive to learn how to apply more advanced latticing and DfAM techniques later down the line.

For existing users of the nTop platform, the goal was to make the transition to the new latticing technology a streamlined experience. To this end, users will find three new easy-to-use blocks that enable them to quickie replicate outputs of workflows using the old latticing technology and therefore transition their existing workflows to the new software.

According to nTopology, one benefit of the new latticing technology is a significant performance increase particularly with lattices with a very high beam and cell count. For instance, a lattice with over 50,000 unit cells used to take between 45 and 60 seconds to generate, whereas it can now rebuild in just one or two seconds, marking a 50x performance increase.

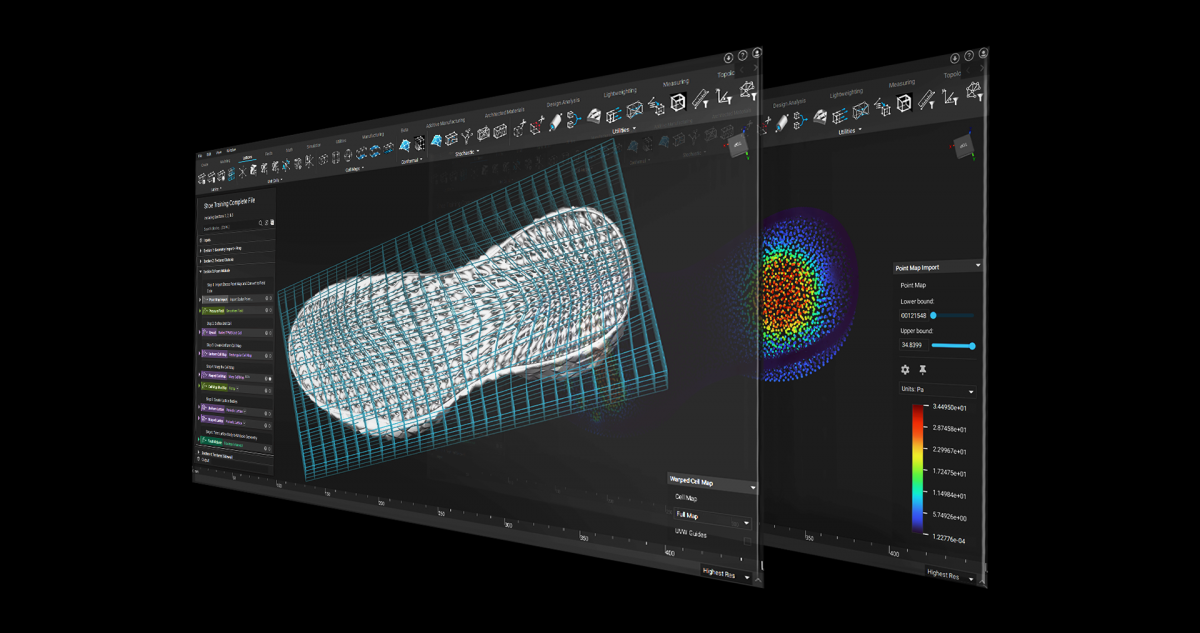

The new latticing technology also comes equipped with several new capabilities to further streamline the lattice design and optimization process. First off, new warping tools allow users to apply field-driven design techniques to control the lattice cell map in the same way they can control its thickness. Combining this feature with real-time visualization enables users to precisely tune complex shapes and design conformal lattices.

Additionally, the new technology offers a unified workflow whether users are working with a graph, TPMS, or custom unit cell, making it simpler to rapidly iterate between different lattice types. Not only does this save time, but it also makes it easier to set up computation design of experiments for optimization.

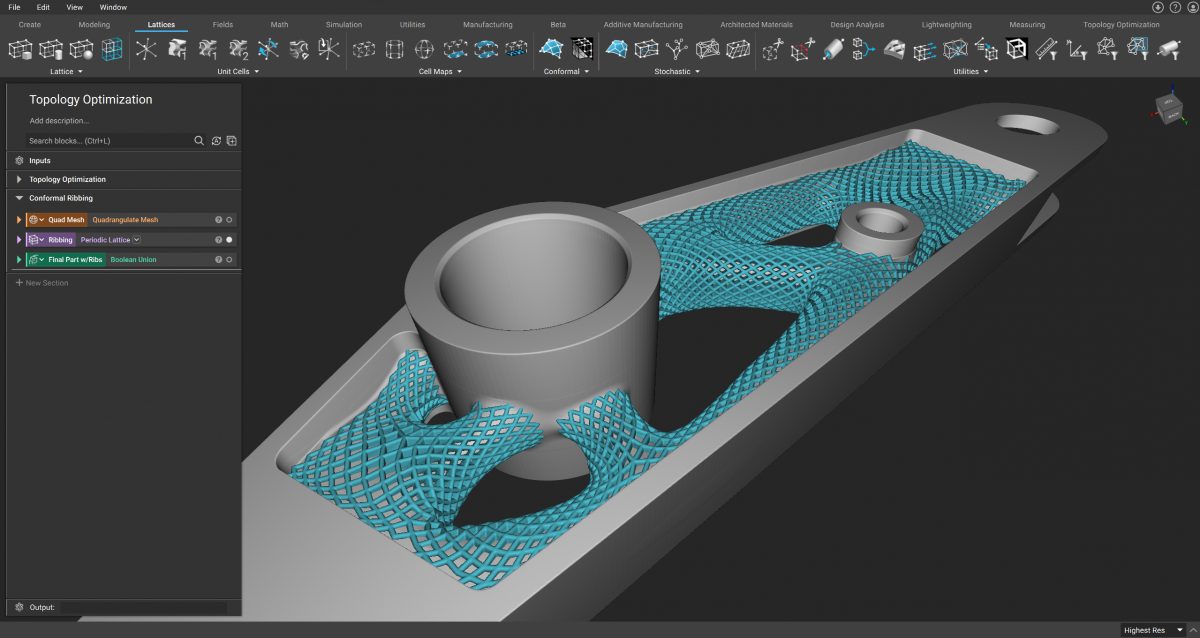

The software also features new filtering utilities that enable users to select lattice beams based on specific criteria like length, angle, connectivity or thickness, meaning they can control certain parameters of their lattice structures and optimize them for manufacturing. Furthermore, users can create cell maps that conform to the surface of a quad mesh, enabling the design of conformal rib grids to increase the stiffness of bodies with even the most complex or organic shapes.

Laying the groundwork for new optimization tools

In addition to offering powerful new capabilities, nTopology’s new latticing technology has laid the foundation for several upcoming optimization tools. The firm is currently developing a novel field-driven optimization capability that aims to enable users to automatically generate lattice structures optimized for their specific engineering requirements, such as targeted stiffness or weight.

The nTopology team is also working on custom graph unit cells. If users wish to use a unit cell type not already covered within the platform, they will be able to sketch their own custom unit cells and define the associated design parameters, including beam thickness, length, fillet radii, and more.

Additionally, the team is working to expand the platform’s conformal lattice generation capabilities to complement the technology’s existing tools. Soon, users will be able to design lattice cell maps that conform to multiple surfaces or organic volumes.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the new tools separate the lattice generation process into three fundamental components: unit cell, cell map, and lattice parameters. Image via nTopology.