New York-based software company nTopology has introduced its latest generative design solution, the nTop Platform.

According to Blake Perez, Application Engineer at the company, “The nTop Platform is helping companies realize new products by integrating the Design for Additive Manufacturing (DfAM) workflow and removing inherent barriers to iterative redesign.”

“Most models and methods for design and innovation suggest that true innovation comes from not just a single event of inspiration, but rather the constant iteration and improvement upon an initial idea or design. Grit prevails over genius.”

To demonstrate the capabilities of the offering, the company is also set to host an nTop webinar in July.

The nTop Platform

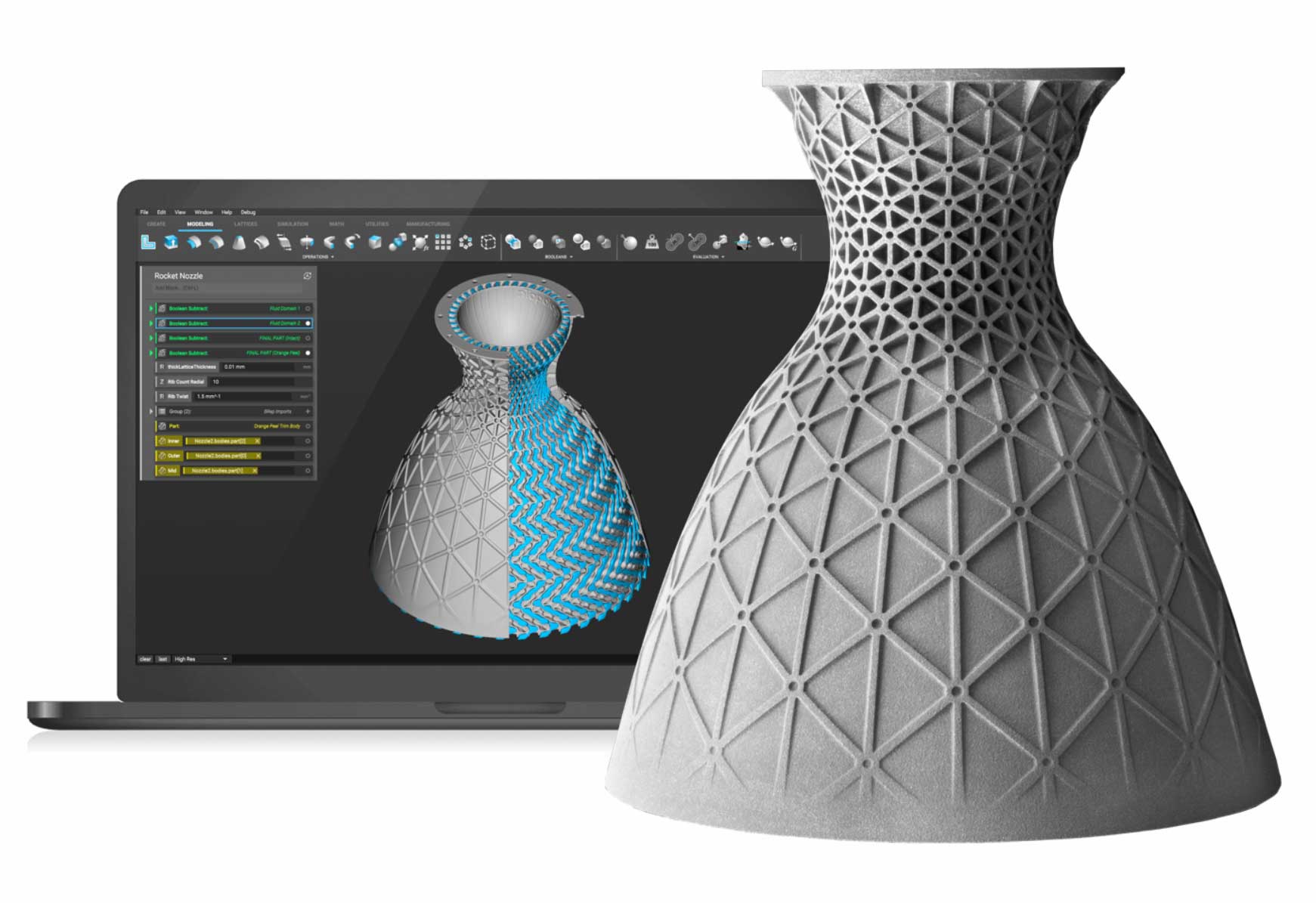

Established more than 3 years ago, nTopology develops generative design software to solve industrial-grade challenges. Element, another software from the company, can optimize lattice structures with user-defined inputs, imported data, or our integrated FEA. Now, with the commercial release of the nTop, engineers will be able to integrate “powerful, unified, product design, analysis,” with manufacturing. This platform uses implicit modeling and field-based design for rapid product development.

“nTop Platform transforms the way teams work, enhancing automation and enables the creation and production of highly complex, innovative products,” said Bradley Rothenberg, CEO of nTopology.

Generative design in the medical sector

nTopology software is being applied in the aerospace, automotive, and medical sectors. Earlier this year, British metal 3D printing specialist, Renishaw, collaborated with nTopology, and research organization Irish Manufacturing Research (IMR) to streamline the 3D printing of spinal implants.

IMR developed the initial designs of an implant using the nTop Platform to mimic the structure of human bone with lattice structures. This was then additively manufactured in titanium material (Ti 6Al-4V ELI) on a Renishaw RenAM 500M 3D printer.

On July 2, nToplogy is hosting a webinar entitled “nTop Platform: Enabling the highest-performing parts, faster” to demonstrate the capabilities of the new software.

Stay abreast of the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter and follow us on Twitter and Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

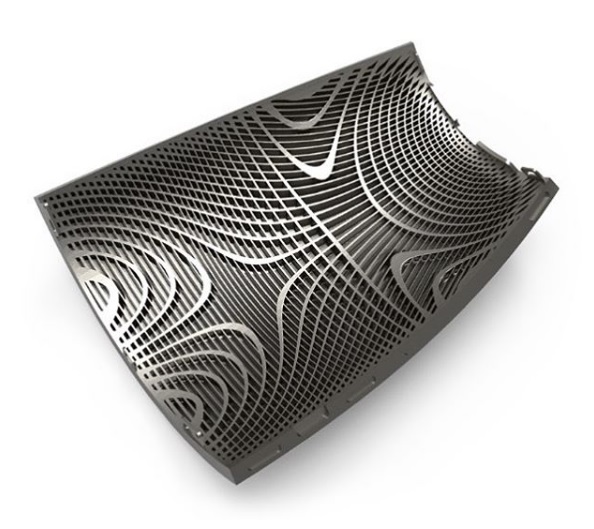

Featured image shows brackets modeled on the nTop Platform. Image via nTopology.