New York based nTopology has raised $7.6M to enhance its generative design software.

The funding round was led by Data Collective and Root Ventures.

nTopology recently returned from exhibiting at formnext 2017. I caught up with Brad Rothenberg, nTopology co-founder and CEO, to learn more about how the funds will be used.

“Formnext was awesome,” says Rothenberg, “Sometimes it seems like AM is a niche industry but then you see 3D printing gaining so much and real use cases everywhere.”

Expanding capability for generative design

Rothenberg is excited to be working with the Data Collective Venture Capital (DCVC) fund, especially as this investment is the first the Silicon Valley firm has made generative design software. DCVC does already have experience in the 3D printing industry with a $75 million investment in Rocket Lab, a company currently testing rocket engines that are partly 3D printed. That investment valued Rocket Labs at over $1 billion.

The precise terms on the nTopology deal have not been released and Rothenberg prefers to focus on how the funds will be used. One immediate action taken at nTopology was to increase headcount, expanding the team by almost double to a current 21 members.

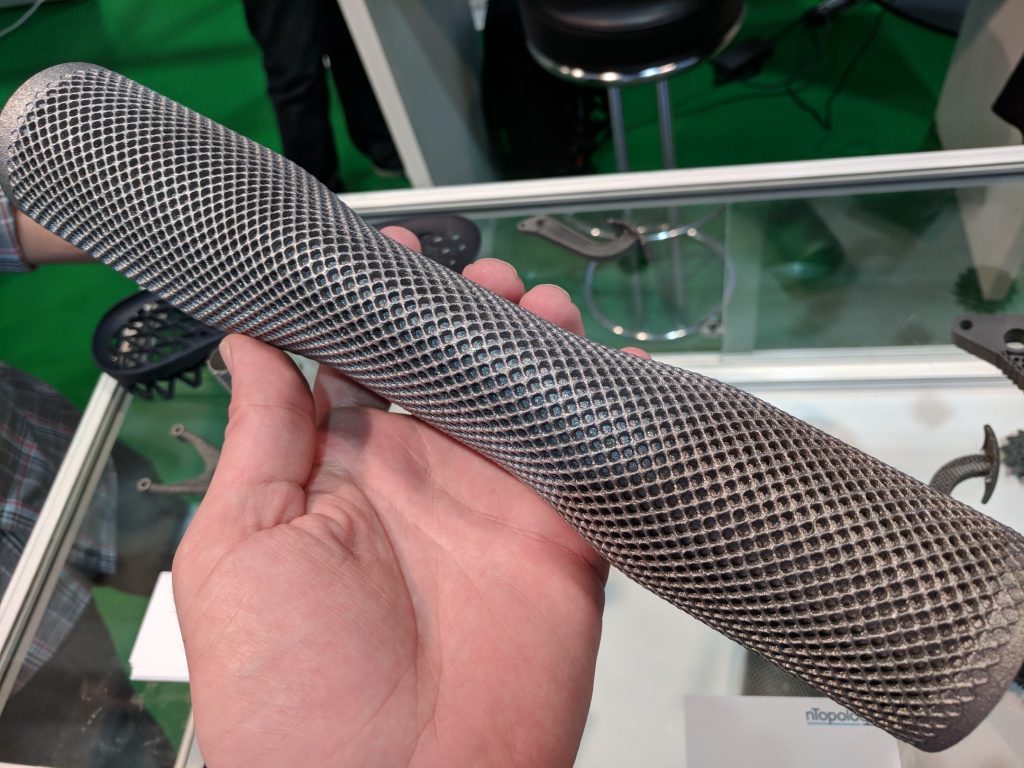

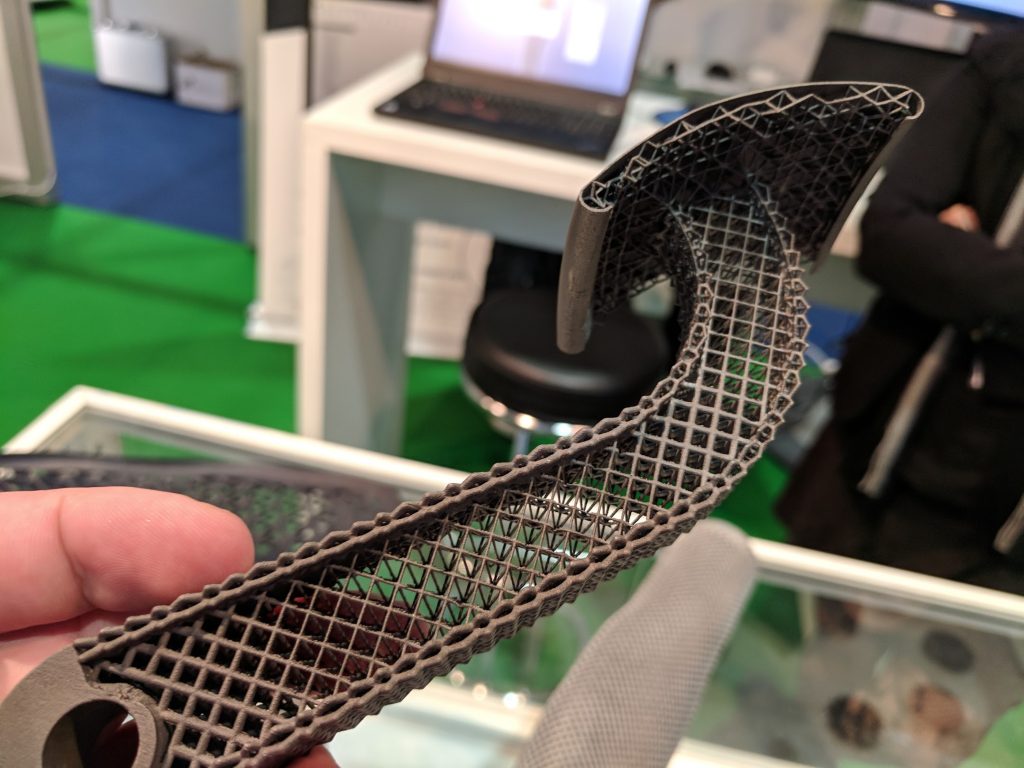

This expansion will allow nTopology to develop the next generation of their software Element. Capabilities will be expanded, adding the ability to use more constraints, additional physics and greater support for manufacturing techniques.

Collaboration is also underway with some of the leading software developers in advanced manufacturing and further news is expected early in 2018.

A revolution in CAD

Rothenberg tells me that his goal is to grow nTopology to, “become the next paradigm and a major CAD player”.

“I expect to see a lot of start-ups in CAD which is really in for a revolution,” he adds.

Specifically this revolution will see a challenge to existing CAD systems, “Design has always been generative, vs. drafting which is representational — The CAD tools originated around drafting, & only as manufacturing has enabled the production of more complex parts has there been a need for generative design tools,” says Rothenberg.

Now, with designs becoming too complex to conceptualize in a single person’s mind, software tools like those provided by nTopology are intended to bring freedom to designers.

Of course, nTopology are not the only enterprise developing generative design tools. However, Rothenberg believes his start-up does have some particular advantages over more established software companies. Specifically, the incumbents, “have a big ship to turn to become generative” whereas nTopology does not have to overcome such inertia.

Other public projects include a long-running collaboration with metal AM specialists Renishaw. This partnership now includes working on training classes to promote a better understanding of Design for Additive Manufacturing (DfAM). This is a topic Renishaw’s director of Global Solutions Centers, Marc Saunders, has previously highlighted as top of the “staircase of AM.”

Nominations for 2018 3D Printing Industry Awards are now open. Let us know who is leading the additive manufacturing industry here.

For all the latest 3D Printing Industry news subscribe to our newsletter and follow us on social media.

Featured image shows Brad Rothenberg from nTopology presenting advanced design tools for 3D printing. Photo by Michael Petch.