3D printer manufacturer Stratasys has announced a partnership with engineering software developer nTopology to streamline the Design for Additive Manufacturing (DfAM) process for jigs, fixtures, and other tooling.

Specifically, the partners will be working together to launch a series of accessible, customizable DfAM programs for their users, starting with the FDM Assembly Fixture Generator.

Pat Carey, Senior Vice President of Products and Solutions at Stratasys, states: “nTopology’s software for additive design is a powerful pairing with our additive manufacturing systems, so it was clear we should work together. Our analysis shows manufacturing applications are currently seeing the most growth in our industry, from $2.8B in 2015 to $25B in 2025, so we focused our first collaboration on serving that segment.”

Stratasys and nTopology

Stratasys’ FDM technology is fairly widespread at this point, as it has been employed in industries such as automotive and aerospace, and is capable of printing advanced materials such as Nylon 12 Carbon Fiber. However, the company believes the adoption rate of the technology is still limited by its reliance on traditional CAD programs, which result in comparatively long lead times and an inability to leverage the design freedom 3D printing is known for. The nTopology partnership is intended to alleviate this issue, enabling users to take the fast track to production in a DfAM-oriented manner.

Bradley Rothenberg, Founder and CEO of nTopology, adds: “We look forward to super-charging the Stratasys additive community with nTop Platform by combining Stratasys expertise with our powerful platform, giving both of our users improved designs with faster time to manufacture. Manufacturing is going through the most profound shift it has seen in 100 years, and the Stratasys | nTopology collaboration brings this unique combined innovation to accelerate that shift.”

The FDM Assembly Fixture Generator

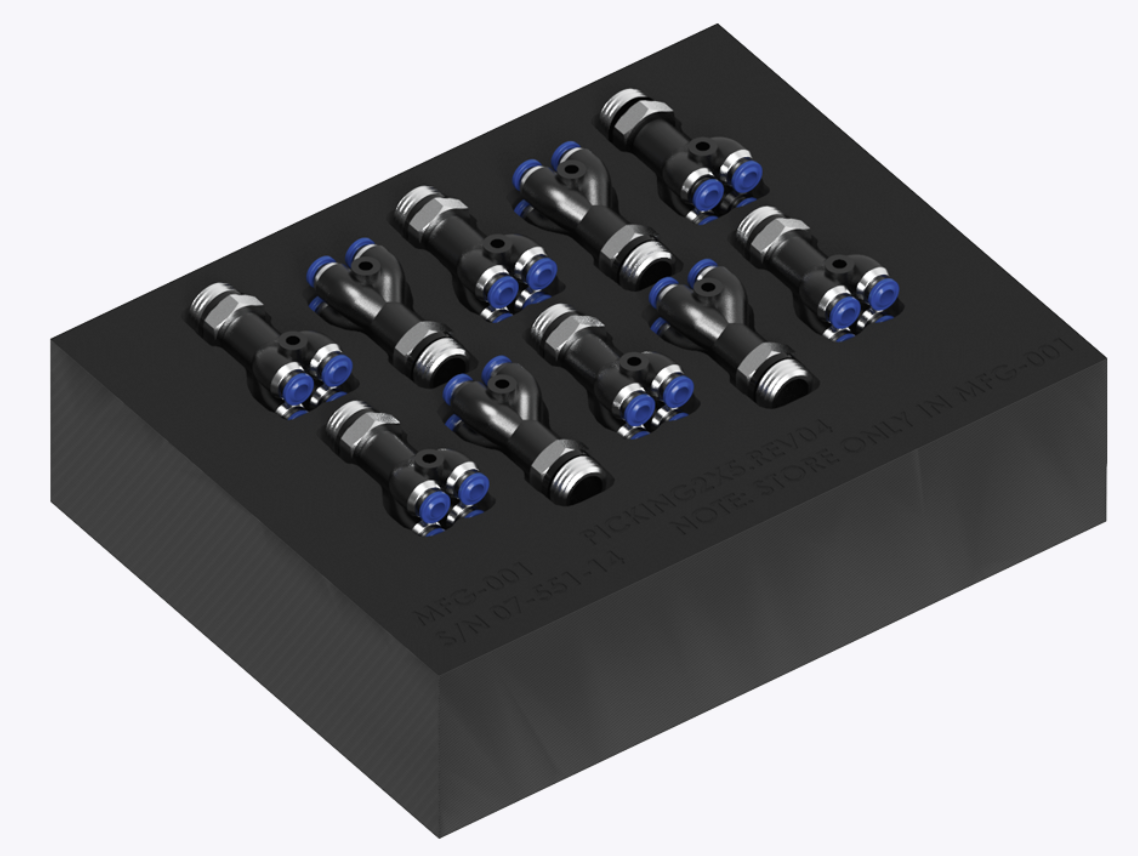

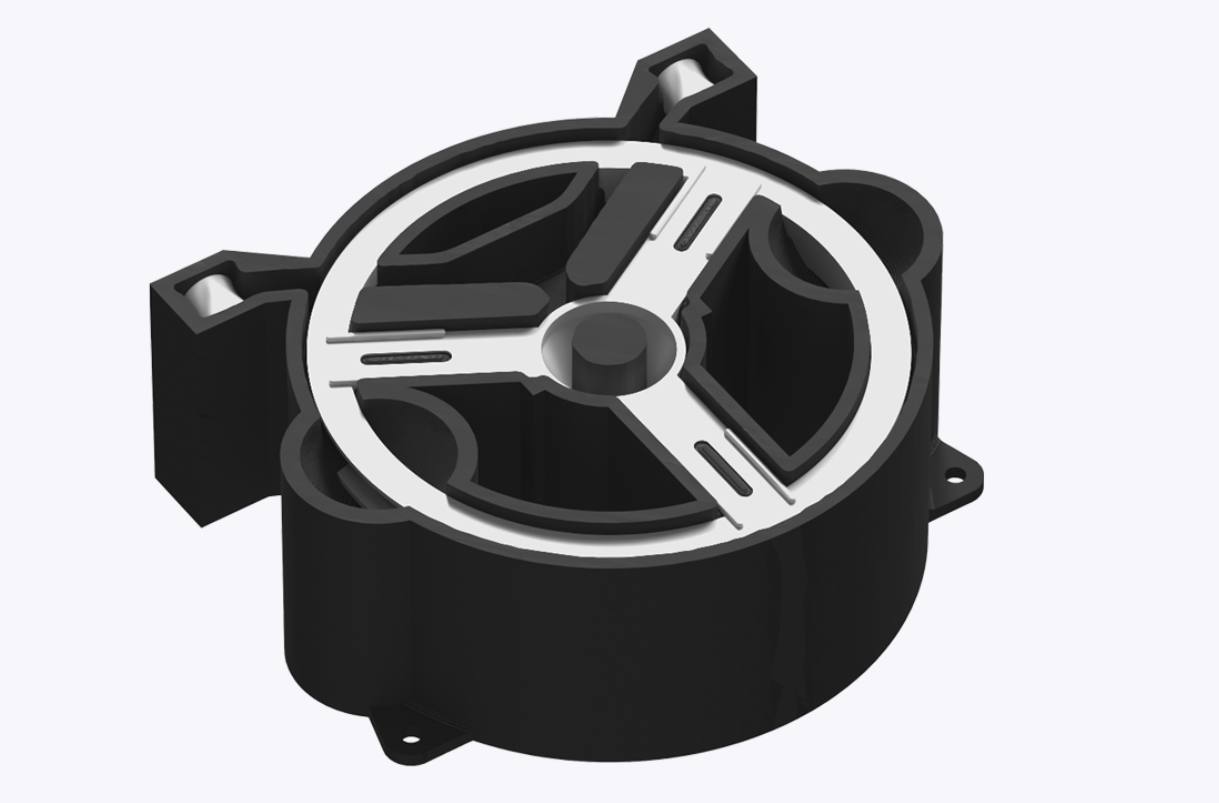

The first of the planned DfAM workflows is ultimately intended to improve production efficiency right at the design phase. It is built to automate the design of jigs and fixtures for the FDM process, allowing engineers to prepare tooling parts in a simple drag-and-drop manner. It does this through the use of nTopology’s well-established topology optimization software engine, which operates on a goal-driven and generative premise to optimize part designs with the end-use application in mind.

nTopology states that a prime use case would be an anti-rotation fixture, for example, which can elevate and position chain wheels for assembly. 3D printing the part would enable users to precisely cradle large components for assembly, regardless of their geometries. A fractal infill pattern can also be used here to save on both material and time.

Available now through the nTop platform with a free trial, the Fixture Generator enables rapid customization and iteration without the use of intensive resources. Alongside the program, the partners will also be providing a series of training videos and additional resources as supplementary material.

Earlier this year, automotive manufacturer Continental AG installed a Stratasys Fortus 450mc FDM 3D printer at its Additive Design and Manufacturing (ADaM) Competence Center in Karben, Germany. The company cites cost effectiveness, high throughput, and electrical safety as key factors to its manufacturing success, which it reportedly sees in Stratasys’ 3D printing technology.

Elsewhere, aerospace manufacturer Boeing recently qualified Stratasys’ Antero 800NA thermoplastic filament for flight parts. As such, the PEKK-based polymer can now be used to additively manufacture end use components aboard Boeing’s planes, boding well for the future of the company’s FDM systems in the aerospace sector.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Stratasys’ F123 series of FDM 3D printers. Photo via Stratasys.