Researchers at Cornell University have come up with a novel biomaterial that can be used to create artificial skin capable of mimicking the behavior of natural human tissues.

Thanks to its unique composition, made up of collagen mixed with a ‘zwitterionic’ hydrogel, the team’s biohybrid composite is said to be soft and biocompatible, but flexible enough to withstand continued distortion. While the scientists’ R&D project remains ongoing, they say their bio-ink could one day be used as a basis for 3D printing scaffolds from patients’ cells, which effectively heal wounds in-situ.

“Ultimately, we want to create something for regenerative medicine purposes, such as a piece of scaffold that can withstand some initial loads until the tissue fully regenerates,” said Nikolaos Bouklas, one of the study’s co-lead authors. “With this material, you could 3D print a porous scaffold with cells that could eventually create the actual tissue around the scaffold.”

Combining the natural and synthetic

Given the constantly-moving nature of the human body, our tissues need to be both soft enough to bend on command, while also being sufficiently robust to withstand constant loading. When these cells become worn out or damaged, the Cornell team says hydrogels and synthetic materials could serve as replacements, but neither has the right mix of biological and mechanical qualities to do so.

In particular, the scientists suggest that synthetic plastics often lack the ability to support and maintain live cells, alongside the microstructural organization which makes them functional. When it comes to natural polymers such as collagen, fibrin or hyaluronic acid, meanwhile, the researchers maintain that they’re able to replicate the biocompatibility of living tissues, but they tend to be more fragile.

In order to make a bio-ink with the flexibility and cell-friendliness needed to enable the production of lifelike artificial skin, the team has therefore turned to ‘zwitterionic hydrogel.’ Specifically, the scientists have found that mixing collagen with the material, which contains both positively and negatively-charged molecular groups, could allow it to withstand multiple impacts while supporting cellular growth.

“These charge groups interact with the negatively and positively charged groups in the collagen,” explains one of the study’s other co-lead authors, Lawrence Bonassar. “This interaction is what enables the materials to dissipate energy and achieve high levels of toughness.”

A basis for more lifelike artificial skin?

Interestingly, in their paper, the researchers say the formulation of their biohybrid composite required only “simple mixing,” as their collagen self-assembled into a fibrillar network, which in turn, became ionically linked to its surrounding hydrogel. According to Bouklas, this yielded “the same interconnected network of collagen seen in natural cartilage, which otherwise would be extremely hard to produce.”

Once they’d created their material, the team subjected it to lab testing, which showed that compared to an untreated zwitterionic matrix, the addition of collagen had increased its elastic modulus by 40%. Integrating collagen with the hydrogel was also found to enable the material to absorb eleven times more energy before cracking, while giving it properties akin to those of tissues like articular cartilage.

Elsewhere, on the biocompatibility front, the scientists found their collagen-loaded polymer to be over 100 times more capable of supporting cellular growth, and it demonstrated a cell viability of more than 90%. Moving forwards, the researchers say they intend to continue working on the biosynthesis process behind their material, and they’ve now begun to test its viability for the 3D printing of tissues.

Bioprinting’s tissue-production potential

Though 3D printed human tissues generally remain at the lab-testing stage, the technology behind them has come on leaps and bounds over the last couple of years alone. In January 2022, researchers at the University of Birmingham and the University of Huddersfield, revealed that they’d developed a way of treating deep wounds with bioprinted skin.

Similarly, late last year, the NOVOPLASM consortium announced the creation of the ‘world’s first’ 3D printed immunized skin model. Developed using cold plasma technology, the model could be used in future to heal ailments like infected burns and irritated skin grafts.

Away from wound-healing applications, 3D printing has also been used to enable the creation of tissues for skincare product R&D. HK inno.N and T&R Biofab, for instance, have partnered with the aim of developing 3D bioprinted tissues for drug testing applications, which could serve as an alternative to testing on animals.

The researchers’ findings are detailed in their paper titled “Simple synthesis of soft, tough, and cytocompatible biohybrid composites,” which was co-authored by Cameron Darkes-Burkey, Xiao Liu, Leigh Slyker, Jason Mulderrig, Wenyang Pan, Emmanuel P. Giannelis, Robert F. Shepherd, Lawrence J. Bonassar and Nikolaos Bouklas.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

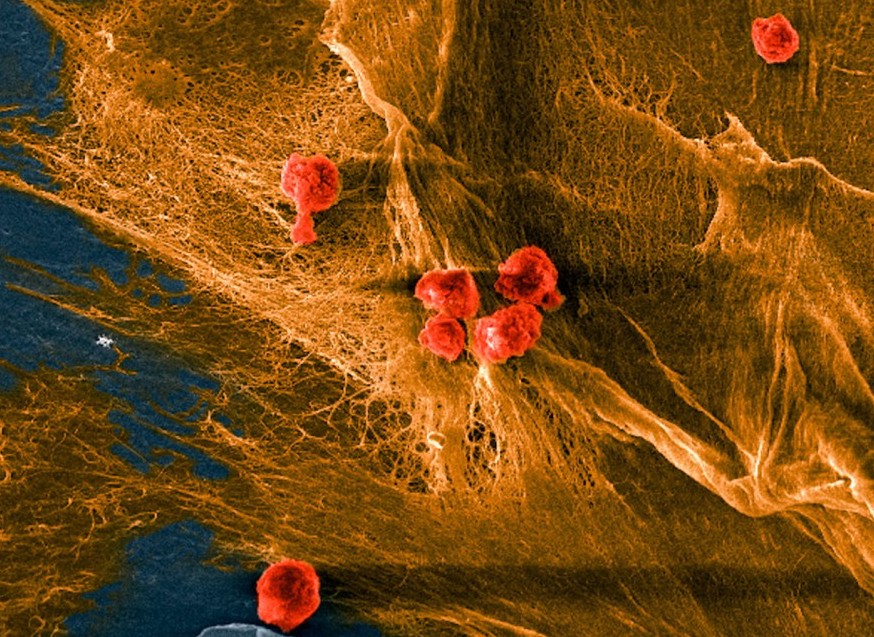

Featured image shows a micrograph image of the team’s biohybrid composite. Image via Cornell University.