Interested in reading more about the year’s biggest 3D printing news? You can access our full 3D Printing Industry Review of the Year series here.

With tensions between Russia, China, and the West continuing to rise, June saw a string of announcements and incidents in which 3D printing got caught in the crossfire. In aerospace and automotive, meanwhile, the technology progressed as a means of producing end-use racecar and rocket engine components.

Whether it be in the creation of human tissues or artificial edibles, 3D bioprinting also took a few steps forward during the month, as the technology carried on its advance towards the mainstream medical and food & beverage industries.

Read on for more from the likes of HENSOLDT, Stratasys, Toyota, the Goodwood Festival of Speed, Airtech, Natural Machines, Ursa Major, Launcher, Skyrora, SPEE3D, 3D Systems and United Therapeutics.

AM gets deployed in conflict zones

As Russia’s invasion of Ukraine ratcheted up global tensions, many Western defense firms and humanitarian groups progressed with developing advanced technologies, to allow them to get ahead of the conflict. That month, HENSOLDT completed a series of ground and field tests for its Kalaetron Attack 3D printed jamming system. Designed for deployment on jets like the Eurofighter, it was said the device could detect even the most cutting-edge air radars and fire off jamming signals to disrupt them.

On the ground, activists began using 3D scanning to archive Ukraine’s heritage sites, targeting those most at risk of being destroyed by bombing. As of mid-June, the Backup Ukraine initiative had seen 6,000 people use a scanning app to create models of monuments and historical sites to safeguard them for future generations.

Interestingly, these simmering tensions didn’t just draw in 3D printing firms based in Russia and Ukraine, but also affected those located in the US and China. In one case, the US Department of Commerce suspended the export licenses of three 3D printing firms: Rapid Cut, US Prototype and Quicksilver Manufacturing. This was in response to the companies’ decisions to subcontract Chinese businesses to 3D print sensitive US military prototypes, including satellite and rocket components.

Going up a gear in automotive

In automotive, June marked a significant step up in the deployment of 3D printing in auto-racing applications. At the Goodwood Festival of Speed, 3D Printing Industry covered the live UK debut of the 3D printed Czinger 21C, a 1,250 horsepower hypercar developed by Divergent Technologies. It would later be revealed that the Divergent Adaptive Production System (DAPS) behind the vehicle is being powered (at least in part) by a series of SLM Solutions’ NXG XII 600 3D printers.

Additive manufacturing also got a run out at the 100th running of the legendary Pikes Peak International Hill Climb. During the event, race outfit Brumos Racing ran a Porsche with Airtech 3D printed upgrades, which were said to make it lighter, more aerodynamic and ultimately faster up the course.

Elsewhere that month, Stratasys was contracted to produce parts for the upcoming GR Cup series. Operating as the official 3D Printing Partner of Toyota Racing Development, the tuning division of Toyota, the firm agreed to develop parts for the Toyota GR86, a sub-£30,000 production vehicle GR Cup competitors are set to race.

3D Printed Food

Away from 3D printing’s mainstream applications in prototyping and short-run production, the food bioprinting industry showed steady signs of growth in June. Digital Patisserie launched its Patiss3 pastry 3D printer, an extrusion system designed to enable chefs, restaurants and industrial biscuit factories to create edibles in freeform shapes at high-speed.

At launch, Marine Coré-Baillais, Founder of Digital Pâtisserie, said: “This 3D food printing technology provides all pastry chefs with a production method enabling them to rethink shapes and flavors by freeing them from time, gravity and handling constraints. This transforms the creativity of an entire industry for the benefit of our taste buds, whether savory or sweet!”

Over in Spain, Natural Machines also claimed to have 3D printed the ‘world’s best tiramisu.’ Using its proprietary Foodini 3D printer, the firm found it was able to faithfully recreate a heart-shaped dessert that won the 2021 Tiramisù World Cup.

These food bioprinting advances were matched by similar strides forward in the medical field. Though implantable organ bioprinting remains some way from reality, 3D Systems and United Therapeutics did announce plans to trial 3D printed lung scaffolds within five years. The companies’ optimism reflected a growing sense in the industry that the technology was progressing. Later in the year, a patient was even treated with a 3D bioprinted nose, fostered on their forearm.

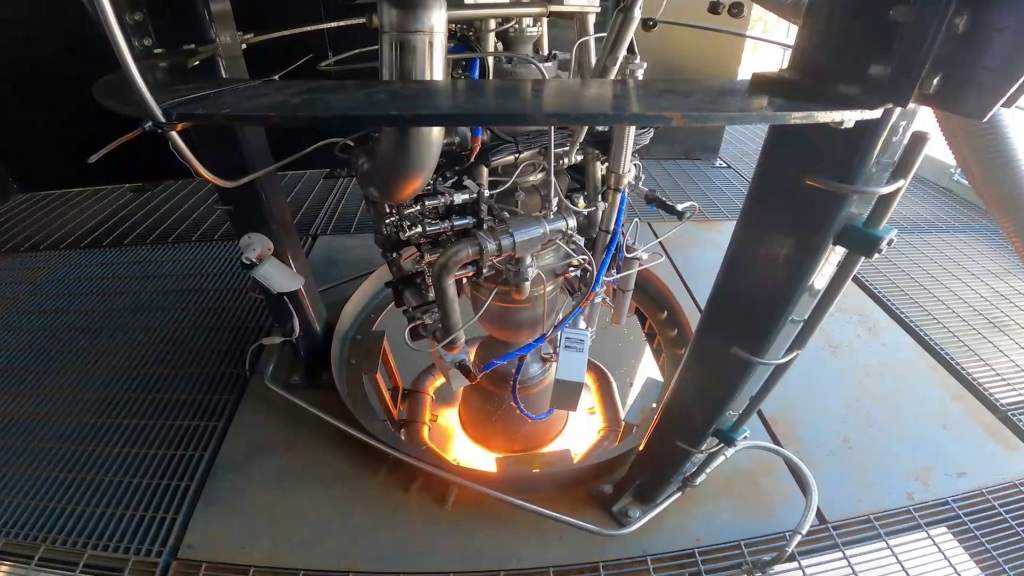

Rocket engines near take off

In the aerospace industry, June saw the continued use of 3D printing to aid the development and performance of rocket propulsion systems. Skyrora’s 3D printed rocket engine, which is set to power the firm’s XL launch vehicle, completed a 70kN hot-fire test. Conducted under a contract awarded by the European Space Agency, the test saw the engine fuelled with a novel propellant and fired for 20 seconds.

Launcher, on the other hand, won a $1.7 million US Space Force contract to help accelerate the R&D of its partially-3D printed E-2 rocket engine, which is known to feature an additive-manufactured combustion chamber and turbopump.

In June, rocket engine manufacturer Ursa Major also introduced an alternative to the now-unavailable Russian propulsion systems used by US launch firms. Manufactured in a manner that takes advantage of 3D printing’s part consolidation and lead time benefits, Ursa Major’s Arroway rocket engine will be marketed as a rival to the RD-180 and RD-181.

Floating the idea of naval 3D printing

In one of several naval 3D printing applications announced during 2022, SPEE3D was selected to supply the ‘MAINTENX’ exercise in June. As part of the initiative, SPEE3D’s systems were deployed both at port and by sea in US Navy ANTX-Coastal Trident 2022 technical demonstrations. The R&D program was said to be a trial of metal 3D printing’s ability to carry out repairs on battle-damaged ships, in a way that could reduce the US Navy’s reliance on traditional supply chains.

“We are thrilled to collaborate with the US Naval Warfare Centers to test and validate our unique metal 3D printing capability,” Byron Kennedy, CEO of SPEE3D, said ahead of the exercise. “We understand their operational challenges both on land and sea, and look forward to strengthening our existing relationships with the US Department of Defense (DoD) as a trusted partner.”

Following the initiative, AML3D was contracted to metal 3D print prototype warship parts for the Australian Navy, in a deal that was seen as a chance to showcase the defense applications of the firm’s Wire Additive Manufacturing process.

2022: 3D Printing Industry review of trends and news

2021: 3D Printing Industry review of trends and news

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows two German Eurofighter jets. Photo via Stefan Petersen, HENSOLDT.