It has been a big week for the rocket 3D printing industry, with Relativity Space and Launcher both announcing significant advances in their aerospace programs.

Relativity Space has revealed that it’s set to attempt its first launch of the 3D printed Terran 1 rocket, with the playfully-named Good Luck, Have Fun or ‘GLHF,’ now expected to take off imminently. At Launcher, meanwhile, the firm has won a $1.7 million US Space Force contract to help accelerate the R&D of the ‘E-2,’ a rocket engine that’s known to feature a 3D printed combustion chamber and turbopump.

“What we’re doing now is taking it to the next level, which is a long-duration test and the turbopump,” Max Haot, Founder and CEO of Launcher, told Space News at a press conference announcing the contract. “We’re also excited that they [the US Space Force] see the value of the staged combustion engine and its high-performance.”

Putting the E-2 through its paces

Since its foundation in 2017, Launcher has devoted much of its efforts to the development of its closed-cycle high-performance E-2 liquid rocket engine. Designed to power the firm’s Launcher Light launch vehicle, which is due to enter service in 2024, the propulsion system is set to be capable of firing payloads of up to 150kg into low Earth orbit (LEO).

During the E-2’s R&D cycle thus far, Launcher has found that 3D printing its parts from copper has been beneficial, in that this unlocks lightweighting opportunities and therefore potential fuel savings. As such, many of the system’s components have been produced via the technology, including its AMCM-3D printed combustion chamber, which is said to be the world’s largest single-piece part of its kind.

Launcher has also deployed additive manufacturing alongside Velo3D and Ansys to improve the performance of the E-2 rocket engine’s turbopump, by fitting it with an upgraded impeller and housings. Through this iterative development process, the company has managed to make significant progress with the E-2, and it achieved full-thrust in hot-fire testing carried out over 40 seconds as recently as April 2022.

Having previously gained a $1.5 million US Space Force contract in 2019, to support the engine’s ongoing development, Launcher has now gained further backing from the same source. Awarded in the form of a SBIR Phase 2B tactical funding increase, or ‘TACFI,’ the additional funding is expected to be used to carry out longer-duration testing on both the E-2’s turbopump and combustion chamber.

Ultimately, Haot says the war in Ukraine has “made it clear that launch vehicles and access to space is strategic,” and his firm hasn’t “seen any slowdown” in demand from goverments, thus he sees a strong market for the E-2 once it’s ready.

Priming the Terran 1 for launch

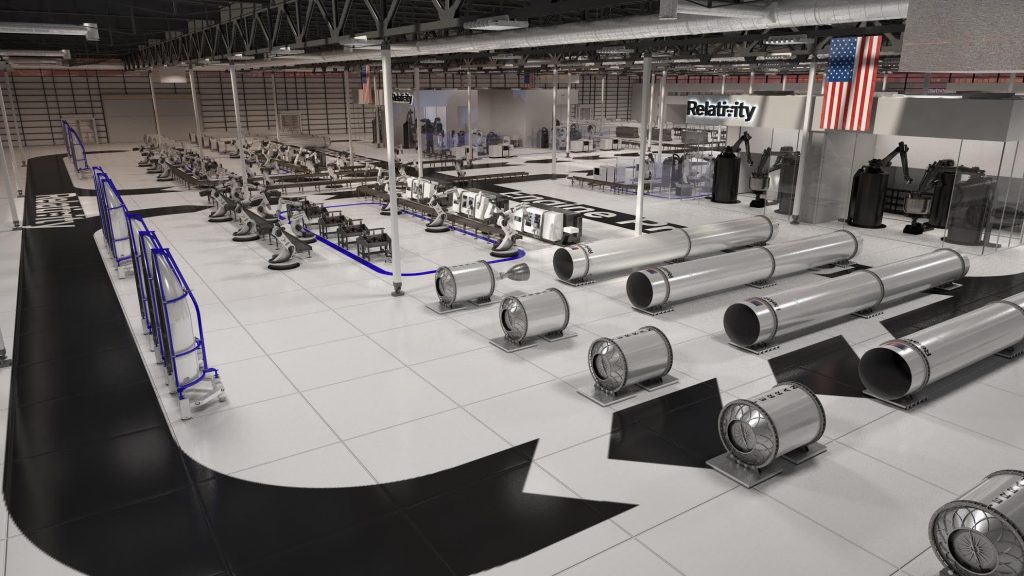

Not content with just 3D printing the engine of its Terran 1 rocket, Relativity Space has made the technology central to the launch vehicle’s production. Built using the automated, robotic arm-mounted Stargate 3D printer, the Terran 1 is designed to carry heavier payloads of up to 1,250 kg into LEO, making it ideal for constellation launch and resupply missions.

The rocket’s additive manufactured parts, which are said to make up 85% of the total build, include its 3D printed AEON engine, a system that thanks to consolidation unlocked via the Stargate, itself only features 100 components. Another impressive aspect of the Terran 1 lies in its 14 foot-tall 3D printed fuel tank, a part that when created in 2017, was seen as a first step towards printing a full 90-foot rocket.

Since then, Relativity Space has gained significant backing to fund the Terran 1’s development, including the closure of a $650 million funding round last year, which took its total raised to over $1.2 billion. With contractors increasingly confident that the rocket will perform as expected, the firm has also been awarded satellite launch deals, by the likes of Iridium Communications and Telesat.

Likewise, Lockheed Martin chose Relativity Space to facilitate an upcoming cryogenic testing mission back in 2020, and the firm has gained a $3 million NASA launch contract as well, in which the Terran 1 is set to be used to fire several small satellites into orbit.

Despite the rocket’s debut launch being delayed from ‘late-2021’ to ‘summer 2022,’ it now appears to be ready for take-off. While the date of its maiden flight is yet to be revealed, the Terran 1 is understood to be launching from Launch Complex 16 in Cape Canaveral, and this will take place without a client payload, given that it represents a first attempt.

Meeting a sky-high demand for rockets

While the economic climate continues to prove challenging for big business, this doesn’t seem to have harmed demand for advanced rocket-related technologies, with rising global military tensions driving high government-level demand. Aerojet Rocketdyne’s 3D printed scramjet engine, for instance, was recently deployed in a hypersonic cruise missile trial, carried out by US Department of Defense bodies.

In more recent events, Ursa Major has unveiled plans to introduce its own 3D printed rocket engine, capable of replacing the Russian-made RD-180 and RD-181, which are no longer available to US aerospace firms. Set to feature several consolidated 3D printed parts, and deliver 200,000 pounds of thrust, the ‘Arroway’ is expected to facilitate satellite launches as well as missions of US national importance.

Across the pond, in the UK, Orbex has also unveiled the first full-scale prototype of its Prime orbital space rocket. Built with the help of SLM Solutions and EOS company AMCM, the 19-meter-long launch vehicle is understood to be fuelled by a renewable bio-propane, that produces 90% fewer emissions than kerosene-fuelled rockets.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Launcher conducting a hot-fire test of its 3D printed E-2 rocket engine at NASA’s Stennis Space Center. Photo via Launcher/John Kraus Photography.