Aerospace and defense contractor Lockheed Martin has enlisted the help of California-based rocket-building firm Relativity Space to 3D print projectiles for an upcoming experimental NASA mission.

The contract, which has been awarded as part of NASA’s Tipping Point program for advancing new technologies, will see several different cryogenic fluid management systems launched into orbit and tested. Utilizing Relativity’s 3D printing technology, Lockheed aims to construct complex rockets to carry the potentially-dangerous cargo with reduced lead times, for a launch date in 2023.

Tim Ellis, Relativity’s Founder and CEO, explained that the company’s top-to-bottom additive manufacturing approach is an ideal fit for the NASA mission: “We’re building a custom payload fairing that has the specific payload loading interfaces that they need, as well as custom fittings and adapters,” said Ellis. “It still needs to be smooth of course, and to a lay person it will look like a normal rocket.”

NASA’s Tipping Point Program

As part of its Tipping Point Program, NASA has awarded fixed-term contracts worth over $370 million to fifteen companies that are pursuing potentially transformative space-faring technologies. Many of these contracts will eventually be combined, forming three overall space demonstrations, involving closed-loop descents, exploring lunar surfaces and cryogenic fuel management.

Lockheed received $89.7 million, the highest amount of funding given to any participant in the cryogenic category, in a section that also included aerospace veterans such as Eta Space, the ULA, and SpaceX. NASA has stated that managing cryogenic fluids is crucial to ensuring a permanent presence on the Moon, and Lockheed will now play its part in developing a rocket for in-orbit testing.

The mission itself is set to involve conducting evaluations on a dozen different cryogenic fluid management systems, including liquid hydrogen, a potentially flammable and difficult to contain material. What’s more, the tests are set to take place on a single craft in orbit, which will require a both a complex design process, and parts that can be manufactured with a high degree of accuracy.

Lockheed plans to work with NASA and its partners to design and build the cryogenic systems itself, but the company will need to work closely with its launch provider during development. In order to optimize the design flexibility of the rocket, and build it in the quickest time possible, the firm has opted to sub-contract Relativity Space, to 3D print the projectile in one single piece.

Relativity’s role in the experimental mission

Relativity Space has been developing a fully-3D printed launch vehicle since 2015, and it has reached several milestones in that time. The company successfully printed a 14-foot-tall fuel tank for the Terran 1 rocket in October 2017, and since then, it has conducted more than 200 hot-fire tests of its AEON engine.

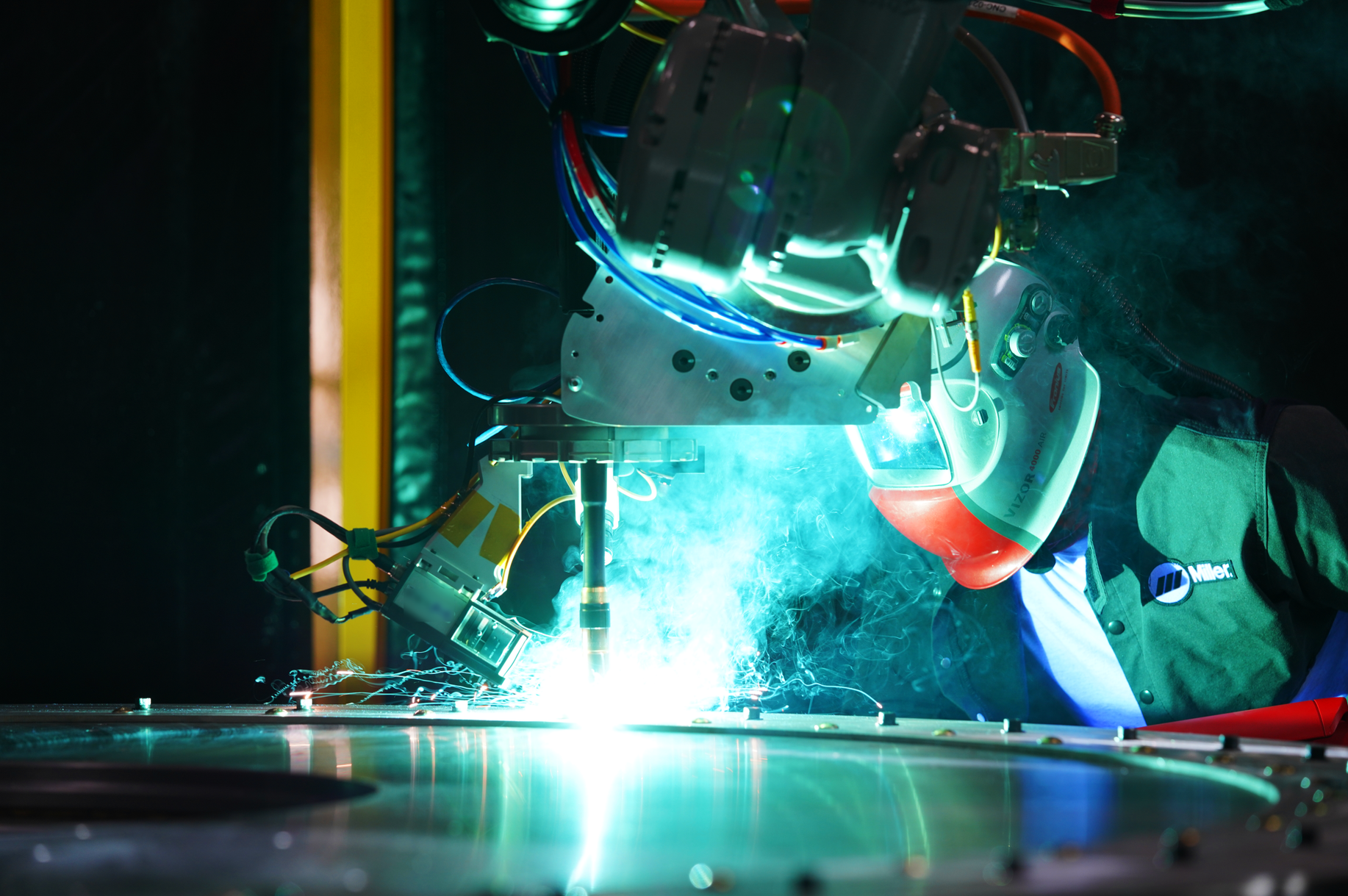

At the center of Relativity’s production process is its Stargate 3D printer, which operates using multiple mechanical arms, and is reportedly capable of producing an entire Terran rocket in just 60 days. According to Ellis, the technology could revolutionize the designs that can be achieved with space-faring vehicles, while drastically reducing the time taken to construct them.

“If you look at the manufacturing tools being used today, they’re not much different from the last 60 years,” explained Ellis. “It’s fixed tooling, giant machines that look impressive but only make one shape or one object that’s been designed by hand, and it’ll take 12-24 months to make it. With our 3D-printed approach we can print the entire fairing in under 30 days.”

Within the upcoming cryogenic NASA mission, Relativity will deploy its Stargate system as a means of developing a complex rocket which could require parts to be reconfigured right up until launch. Using traditional manufacturing techniques to introduce such changes could take up to two years, but Relativity’s software-defined process enables dimensions to be rapidly adapted when needed.

“For this particular object we have some custom features that we’re able to do more quickly and adapt,” added Ellis. “Even though the mission is three years out, there will always be last minute changes as you get closer to launch, and we can accommodate that. Otherwise you’d have to lock in the design now.”

Having got the nod from Lockheed Martin, Relativity will now get to take part in its first NASA-contracted mission, and the firm sees it as an opportunity to showcase its AM technology. By the time the NASA mission is concluded in 2023 though, the company will already have made its first private orbital test, which is scheduled for late 2021.

Additive manufacturing in space exploration

Numerous aerospace firms have made significant progress in the production of 3D printed rockets in recent years, and many of them even have launch dates scheduled in the near future.

British aerospace company Orbex has announced that its 3D printed rockets will be the first to launch from the UK’s new spaceport in early 2022. The projectiles’ single-piece engines are set to be fabricated by the German manufacturer SLM Solutions.

Rocket Lab, meanwhile, has seen its 3D printed Electron Rocket raised onto its launchpad ahead of the company’s upcoming mission with the U.S. Space Force. The rocket, powered by two fully-fabricated Rutherford engines, is scheduled to launch microsatelites into orbit in Q3 2020.

Elsewhere, the US-based start-up Rocket Crafters Inc. (RCI), has concluded testing of its Comet Series hybrid 3D printed rocket engine. Having completed 49 lab tests, the evaluations were designed to be a large-scale proof of concept, ahead of a planned test flight later this year.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows concept art of a Relativity Space rocket taking off. Image via Relativity Space.