Rocket engine manufacturer Ursa Major has introduced a 3D printed alternative to the now-unavailable Russian propulsion systems used by US launch firms.

Just like Ursa Major’s previous efforts, its new ‘Arroway’ liquid oxygen and methane-staged combustion engine is being built using 3D printing, in a way that’s said to yield lead time and part consolidation benefits. Once ready, the system is set to be marketed as a rival to the Russian-made RD-180 and RD-181, which are no longer an option for US companies due to rising tensions over the ongoing war in Ukraine.

“Arroway is America’s engine of the future,” says Joe Laurienti, Founder and CEO of Ursa Major. “Medium and heavy launch capacity is what US launchers desperately need right now, and because Ursa Major focuses solely on propulsion, we’re in a unique position to deliver high-performing, reliable and affordable engines.”

Ursa Major’s launch opportunity

Based in Colorado, Ursa Major prides itself on being the USA’s only privately-funded company that focuses solely on the development of rocket propulsion systems. Thanks to its engineering team, composed of experts in combustors, engine cycles and turbomachinery, the firm has built and tested more than fifty staged-rocket engines to-date, and it plans to ship twenty four of these by the end of 2022.

Thus far, Ursa Major’s 5,000 pound-thrust ‘Hadley,’ the first US-made oxygen-rich staged combustion engine to be hot fire tested, is the only one of its products to have made it into initial production. That being said, the company is already developing the ‘Ripley,’ a more powerful 50,000-pound thrust rocket engine that’s capable of continuously burning for over four minutes.

According to Ursa Major, its propulsion systems can be deployed in launch, hypersonic flight and on-orbit missions, but with tensions ramping up between the US and Russia, their addressable market may now increase even further.

Following the full-scale invasion of Ukraine in late-February, the US and its allies announced they’d be imposing sanctions on Russia, which responded in kind in early-March. Russia’s sanctions included a ban on selling rocket engines to US firms, and it was anticipated that this could impact Northrop Grumman and the United Launch Alliance, whose vehicles rely on NPO Energomas’ RD-180 and RD-181.

“Today we have made a decision to halt the deliveries of rocket engines produced by NPO Energomash to the United States,” Head of Roscosmos Dmitry Rogozin reportedly told the Russia 24 TV channel at the time. “Let me remind you that these deliveries had been quite intensive somewhere since the mid-1990s.” He added: “let them fly on something else, their broomsticks, I don’t know what.”

A US-made 3D printed alternative?

Ursa Major’s answer to Russia’s sanctions is the Arroway, an even more powerful rocket engine that, when deployed in a cluster, could displace the Russian-made RD-180 and RD-181. Set to be capable of 200,000 pounds of thrust, the new system is designed so that most of its parts can be 3D printed, enabling its rapid iteration during development, and its future production to be scaled where needed.

The Arroway’s also built around the same fuel-rich staged combustion architecture as its Hadley and Ripley predecessors. As such, Ursa Major says that its latest rocket engine continues to benefit from the same “high-performance specific impulse and thrust-to-weight ratio,” as well as a “high reliability in mass production and long reusable life.”

Although the company is already accepting orders for the Arroway, it’s not expected to be ready for shipping until 2025, with initial hot-fire testing slated for 2023. Once primed for deployment, Ursa Major anticipates that the system will be capable of addressing markets ranging from US security and commercial satellite launches, to serving space stations and even “missions not yet conceived.”

“Launch organizations should consider whether they have the in-house experience, expertise, time, money, test facilities, and organizational fortitude to build their own engines,” said Jeff Thornburg, former SpaceX Propulsion Executive and Ursa Major Advisor. “The growing space industry is just starting to learn how difficult propulsion development can be and how long it really takes to qualify hardware in-house, which presents an incredible opportunity for Arroway to serve the industry.”

“Arroway is the rocket engine that the industry needs, and Ursa Major is the right company to build it.”

Rocket 3D printing in the USA

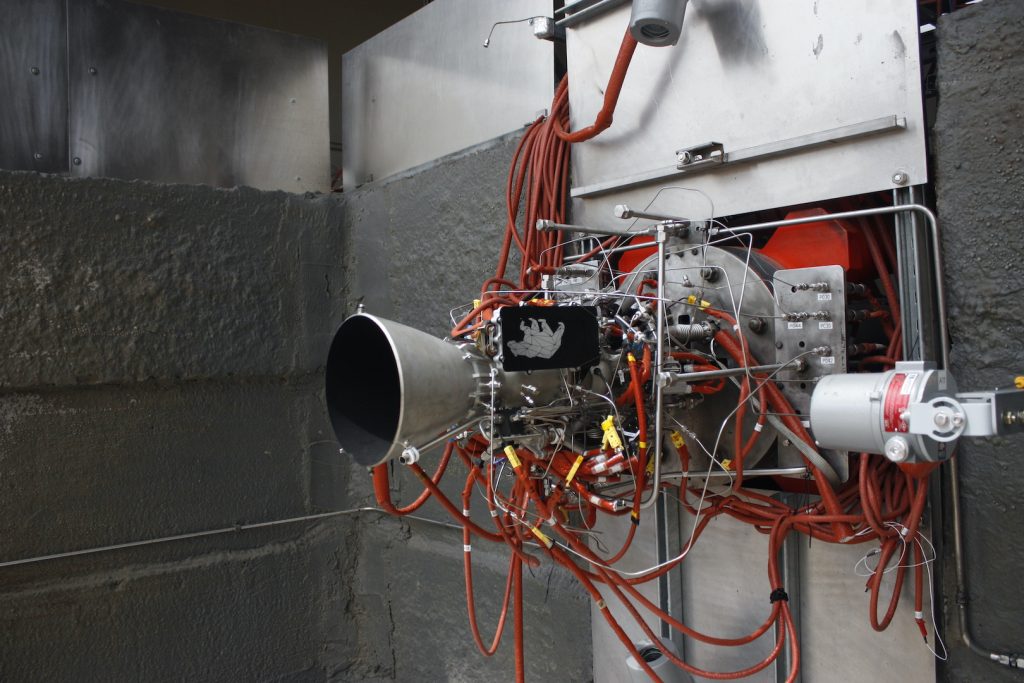

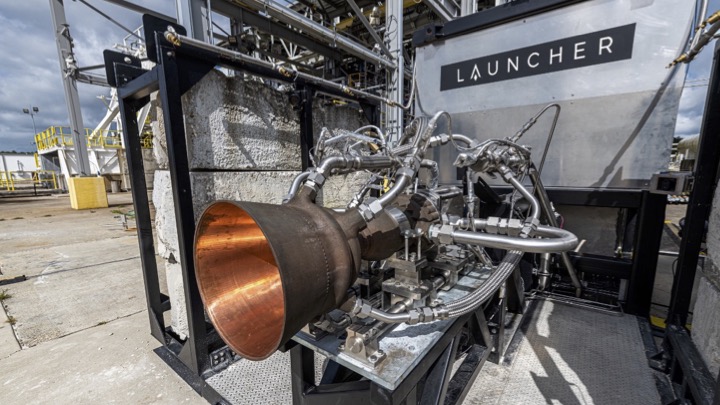

Ursa Major is hardly the only US aerospace firm to deploy 3D printing in the production of its rocket engines, and the country has become a hotbed of innovation in this area. For instance, California-based Launcher continues to make progress in the development of its 3D printed E-2 liquid rocket engine, testing it at the NASA Stennis Space Center in April 2022.

Elsewhere in the Golden State, Aerojet Rocketdyne has also developed a 3D printed scramjet engine, which was deployed in a recent hypersonic missile trial. Using the technology, the firm is said to have been able to reduce the number of parts in the drive system by 95%, before using it to power the Mach 5-capable X-51A Waverider.

Across the pond, meanwhile, Orbex has unveiled the first full-scale prototype of its Prime orbital space rocket. Featuring a 3D printed engine and turbopump systems, the projectile’s development reflects the growing confidence of manufacturers in the UK’s thriving space sector, something that could be beneficial to their US partners in future.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rendering of Ursa Major’s Arroway rocket engine. Image via Ursa Major.