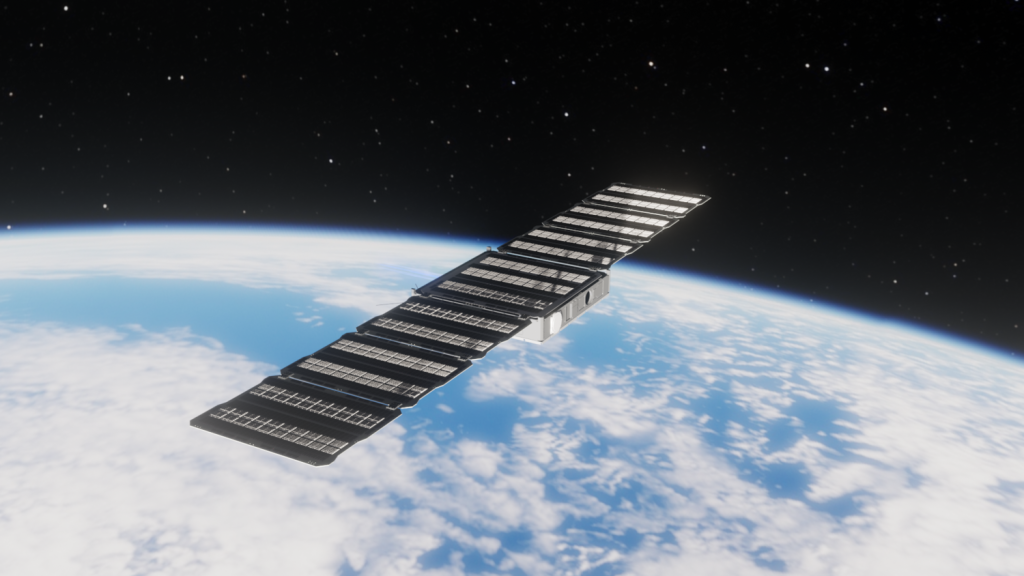

Fleet Space, an Australia-based satellite developer, has successfully launched its new partially-3D printed Centauri 5 satellite on board the SpaceX Falcon 9 Transporter-5 mission.

The next-generation micro-satellite features a set of all-metal patch antennas that were entirely 3D printed, which the company believes is a world-first. Weighing in at just 12kg, Centauri 5 has been placed in Low Earth Orbit (LEO) at an altitude of around 530km.

It joins six other satellites in the company’s existing Centauri constellation, where it’s set to increase data capacity and decrease the latency of its peers. The constellation is operated by both Fleet Space and its partner Tyvak International.

The latest mission was Fleet Space’s third launch with SpaceX, after Centauri 4 was successfully deployed via the Transporter-2 mission back in June 2021.

“We’ve built our business and reputation by consistently delivering on our stated goals, and developing technologies that address real human and commercial needs reliably and cost-effectively,” stated Flavia Tata Nardini, CEO and founder at Fleet Space. “Centauri 5 will bring important new capabilities to our existing constellation.”

Shooting for the stars with Fleet Space

Fleet Space is committing to making a name for itself in Australia’s budding space industry, which the country’s government expects will reach $12 billion by 2030, with an additional 20,000 jobs to boot. The firm first made headlines in 2018 when it launched Australia’s first set of commercial nanosatellites into LEO: the Proxima 1, Proxima 2, Centauri 1, and Centauri 2.

Unsurprisingly, Fleet Space also has a history with additive manufacturing technology. Late last year, the company unveiled plans to launch its Alpha satellites, which it claims is the world’s first entirely 3D printed satellite. Slated for takeoff in 2023, the Alpha constellation will sit among the stars alongside the company’s existing Centauri satellites.

Together, the two satellite systems will aim to provide continuous coverage at data rates of up to 520kbps. Once operational, they will also deliver custom frequency bands to serve a wide variety of advanced IoT devices.

Additionally, the dual constellation will form the backbone of Fleet Space’s ExoSphere system. With the goal of revamping mineral exploration, ExoSphere will leverage ambient noise tomography to pinpoint critical resources up to 100 times faster than traditional methods such as explosives, vibroseis machines, and drilling (all while being far less environmentally damaging).

Nardini adds, “Centauri 5 also supports the development of our forthcoming Alpha constellation, which enables our pioneering ExoSphere mineral exploration tool with transformational benefits for the exploration of critical energy transition materials.”

The new Centauri 5 satellite

Centauri 5’s special 3D printed antennas are defined by their performance. Fleet Space claims the devices can deliver ten times more throughput per kilo of spacecraft than their predecessors, thanks to cutting-edge digital beamforming technology.

With digital beamforming, the firm’s 3D printed antennas offer increased gain, higher data rates, and enable the S-Band frequency channels to be reused across different beams. As a result, Centauri 5’s data capacity is increased by an impressive 2.6x.

Compared to Centauri 4, the new satellite also features defensive upgrades that make it more resistant to radiation in LEO, new direct communication capabilities with Fleet’s ground base, and an improved S-Band range. This allows for uplink to take place at standard ground station frequencies.

The upcoming 3D printed Alpha satellites will also house up to 64 of the advanced all-metal patch antennas.

Despite its myriad of ‘world-first’ claims, Fleet Space isn’t the only company exploring 3D printed satellite components. Just last month, 3D Systems announced that aerospace manufacturer Airbus contracted it to 3D print critical parts for the latter’s upcoming OneSat satellite. Unlike traditional satellites, which are designed for defined missions, Airbus says the OneSat will be fully reconfigurable in orbit for tunable coverage area, capacity, and frequency.

Elsewhere, multinational electronics manufacturer Mitsubishi Electric recently developed a new method of 3D printing freeform satellite antennas in-orbit. The technology revolves around a newly-developed liquid resin, which is not only custom-made for manufacturing in a vacuum, but is capable of photopolymerization via the sun’s UV rays.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Fleet Space Centauri 5 with 3D printed metal patch antennas. Image via Fleet Space.