Japanese multinational electronics manufacturer Mitsubishi Electric has come up with a new approach that enables the freeform 3D printing of satellite antennas in-orbit.

Mitsubishi Electric’s technology revolves around a newly-developed liquid resin, which is not only custom-made for manufacturing in a vacuum, but is capable of photopolymerization via the sun’s ultraviolet (UV) rays. With further R&D, the process is expected to allow for the fabrication of high-gain antenna reflectors in space, as well as large-format parts, far bigger than the dimensions of satellites’ fairings.

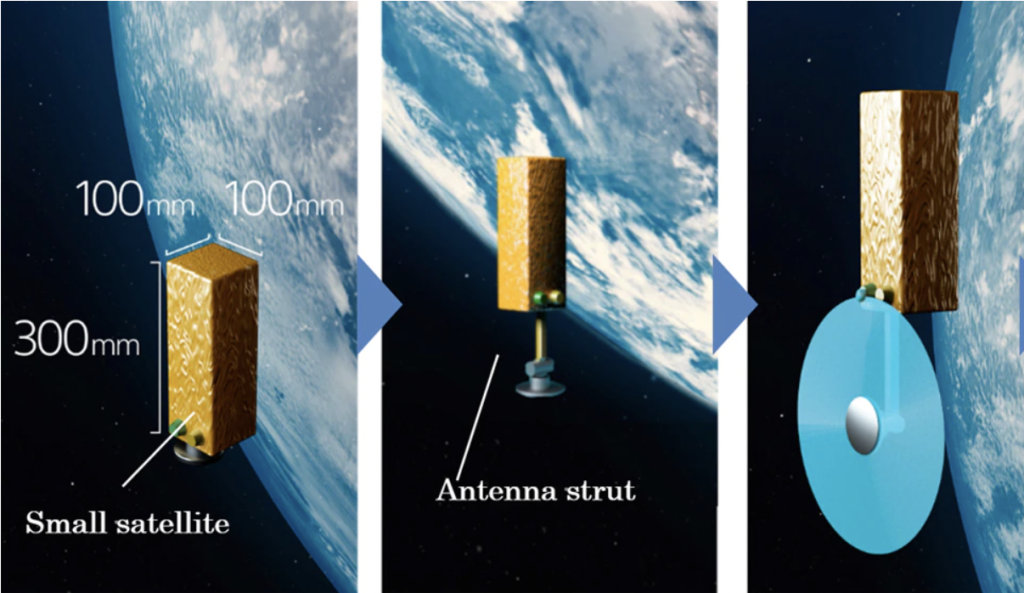

“The technology specifically addresses the challenge of equipping small, inexpensive spacecraft buses with large structures,” says Mitsubishi Electric. “Resin-based on-orbit manufacturing is expected to enable spacecraft structures to be made thinner and lighter than conventional designs, which must survive the stresses of launch and orbital insertion, thereby reducing both total satellite weight and launch costs.”

An alternative to ‘spring-loaded’ satellites?

At present, satellite antennas tend to either be fired into orbit at full-size, or are spring/motor actuated to unfold once in position. While the former naturally take up a lot of space, making them expensive to launch, Mitsubishi Electric says the latter are “mechanically complicated” and prone to failures. Smaller satellites, meanwhile, aren’t able to deploy large high-gain antennas at all, due to size limitations.

Given the growing popularity of such devices, often described as ‘SmallSats’ or ‘CubeSats,’ the company has therefore identified a pressing need for one with enhanced signal-relaying capabilities. While Mitsubishi Electric revealed little about its new solution to this issue during the technology’s recent unveiling, its researchers published a paper on it back in 2019 that does shed some light on its functionality.

In their study, the engineers highlighted how inflatable antennas have been experimented with by teams at the Massachusetts Institute of Technology (MIT) and NASA’s Jet Propulsion Laboratory. Though the team admitted that these devices possess “a high ratio of stowed volume to final deployed diameter,” they add that such satellite antennas “lack the surface quality for frequencies above X-band.”

To realize a truly-optimized SmallSat, the Mitsubishi Electric researchers say that antennas must therefore avoid being compromised by any need for folding or deflating. The team’s alternative to this? a 3D printer and novel resin, designed to be immune to shocks, and once in-orbit, to be polymerized into parts with a submillimeter-level of smoothness and high-frequency capabilities.

Mitsubishi Electric’s 3D printing study

Although it’s likely that the team developing the technology at Mitsubishi Electric’s Research Laboratories (MERL) have made improvements to their methodology over the last three years, their paper does at least indicate how it works.

In essence, the proposed MERL 3D printer is a minimalist hub, complete with an extruder, spin motors and positioning actuators, designed for mounting onto a spacecraft bus. Once installed, the system is built to extrude a custom resin into freeform antenna patterns, which is formulated specifically to be photopolymerized by the sun, and not under other conditions, such as fluctuations in heat or radiation.

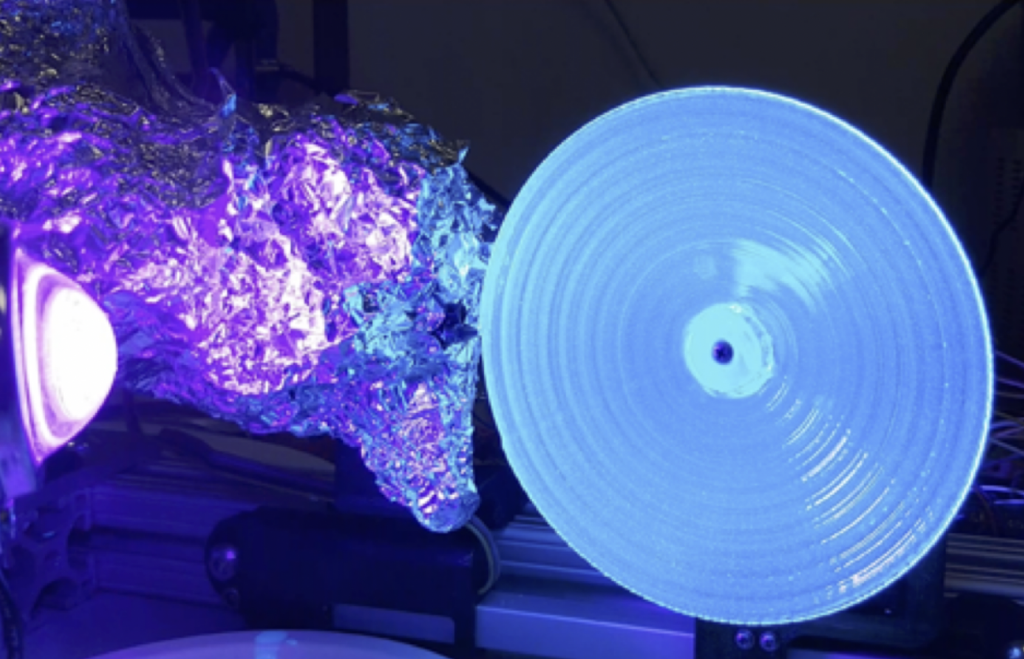

To validate their in-orbit 3D printing approach, the MERL team established an experimental test setup, in which an Arduino-controlled extruder was used to eject material into a 500mm spherical vacuum chamber. Even though the chamber’s dimensions limited the size of the researchers’ initial builds, they found it possible to remotely print 160mm-wide paraboloid reflectors, via an extrusion control software.

During later experiments, the resulting parts were then subjected to radio frequency (RF) characterization, in tests that saw 10, 13.5 and 20 GHz waves fired at them in an anechoic RF test chamber. While results showed that the components offered a weaker gain than that needed by a conventional CubeSat, the team maintained that with a better dipole feedpoint, they could focus wavelengths as short as 1mm.

Back in 2019, the engineers concluded that their work had demonstrated a “proof of concept of some, but not all” the technologies needed to carry-out freeform 3D printing in-orbit, but given Mitsubishi Electric’s recent revelation that its method is ready for action, it appears that any obstacles to this have now been overcome.

“Mitsubishi Electric’s innovative approach—resin-based on-orbit manufacturing—efficiently realizes high-gain, wide-bandwidth, large-aperture antennas deployed from a lightweight, vibration-resistant launch package,” concludes Mitsubishi Electric. “By developing a 3D printer that extrudes a custom ultraviolet-curable resin formulated for vacuum, resin-based low-power freeform additive-manufacturing in space has now become possible.”

Advancing in-orbit additive manufacturing

The idea of 3D printing advanced parts from a liquid resin in space using only the power of the sun, may sound more science fiction than science fact, but it’s not the first time this has been proposed. As long ago as 2016, Part Time Scientists worked with Audi to develop the ALINA lunar lander and the Audi Lunar Quattro rover, in a project that moved lunar microwave 3D printing a step closer to reality.

When it comes to additive manufacturing satellites in-orbit, the technology has also come on leaps and bounds since then, with researchers at the Munich University of Applied Sciences developing a novel Low Earth Orbit 3D printer. Built last year as part of the ‘AMIS-FYT’ project, the team’s extrusion system is specifically designed to construct solar panels or antennas in zero-gravity conditions.

More recently, engineers at the University of Sydney and University of Science and Technology of China have even managed to design an in-orbit FFF 3D printer with high-temp capabilities. Using Proportional Integral (PI) controllers, the system is capable of operating at up to 400°C in a vacuum, potentially making it ideal for carrying out orbital repair missions.

More on Mitsubishi Electric’s technology can be found within its study on the subject, entitled: “On-Orbit Additive Manufacturing of Parabolic Reflector via Solar Photopolymerization.” The paper was co-authored by Avishai Weiss, William S. Yerazunis, Patryk Radyjowski and Richard Cottrell.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows one of the researchers’ initial paraboloid reflector builds being 3D printed. Photo via Mitsubishi Electric.