The UK Space Agency has announced several new milestones for the UK’s thriving space sector, including the first satellite launch on UK soil.

The launch of the European Space Agency’s (ESA) long-awaited Prometheus-2 rocket engine will take place later this summer from Spaceport Cornwall in Newquay, firing two cubesats into low Earth orbit (LEO) to monitor radio signals including GPS and sophisticated imaging.

Meanwhile, British aerospace firm Orbex has unveiled the first full-scale prototype of its Prime orbital space rocket, of which the engine and turbopump systems are 3D printed.

“Space technology is crucial for developing defense capabilities and the launch of Prometheus-2 represents another important step forward for our homegrown space program,” said Jeremy Quin, the UK government’s Defence Procurement Minister.

“This collaboration with In-Space Missions and Airbus paves the way for the UK to become a more resilient, more robust, and more significant global space entity.”

The Prometheus project

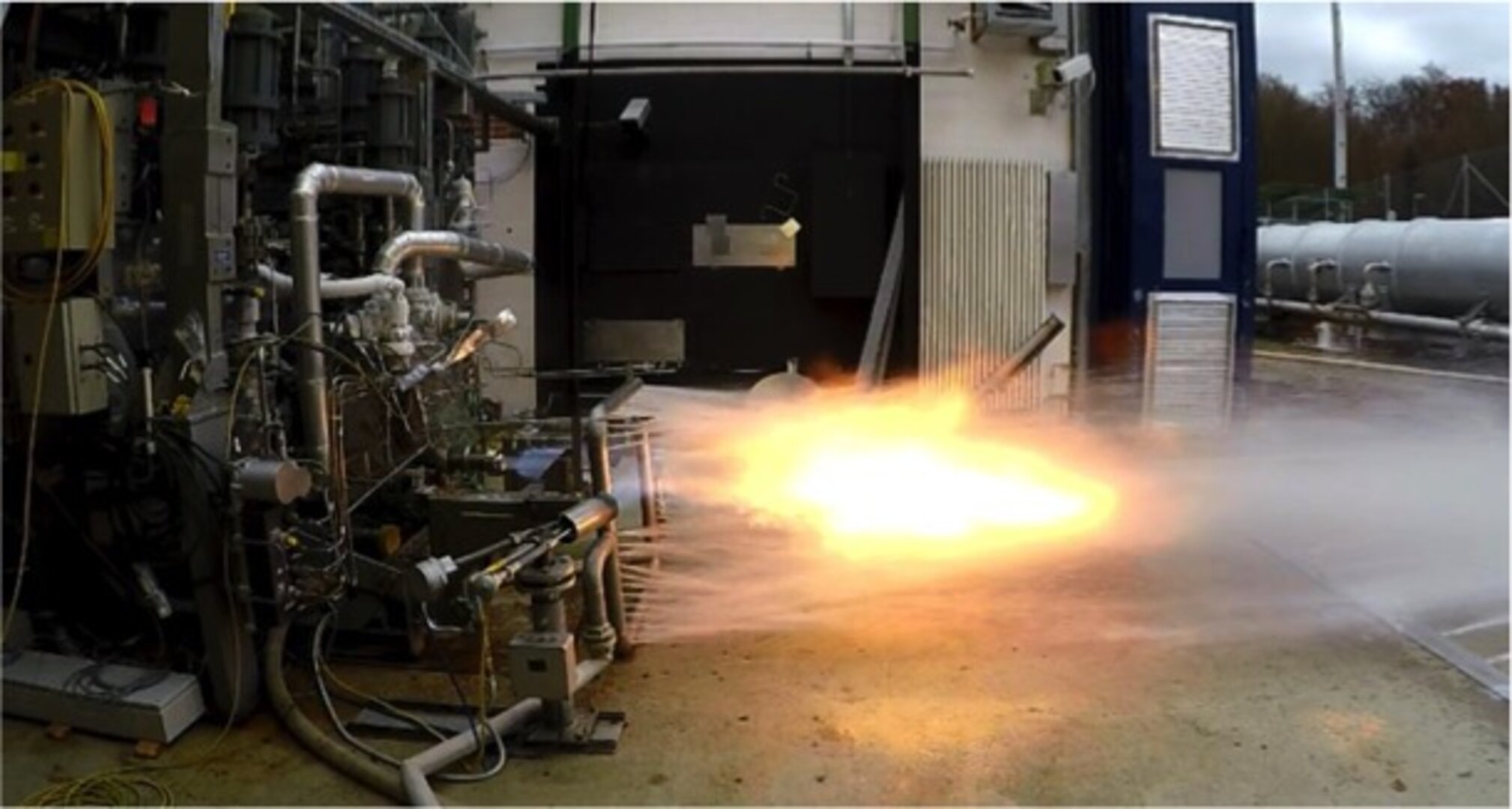

The Prometheus rocket engine has been in development since 2017, when the ESA signed a €75 million contract with the Ariane Group for a reusable, low-cost, next-generation rocket engine that made use of innovative manufacturing technologies such as 3D printing.

Ariane Group is a joint venture of multinational aerospace firms Airbus and Safran, and had begun prototyping the engine with metal 3D printing methods in 2015. One of the predecessors to the Prometheus, the Vulcain 2.1, contained 3D printed structural components. The project has since focused on producing the Prometheus at costs ten times lower than conventional rocket engines through the extensive use of additive manufacturing.

In 2018, GKN Aerospace was contracted by Ariane Group to 3D print two full-scale turbines for the liquid oxygen-methane propelled Prometheus engine. According to GKN, leveraging additive manufacturing technologies enabled higher performance, lower lead times, and a 90 percent cost reduction for critical components within the turbines.

Countdown to launch

After years of development, the Prometheus-2 rocket engine will be launched for the first time this summer to send two cubesats into LEO. The Prometheus-2 was built by Hampshire-based In-Space Missions and designed with Airbus Defence and Space, the UK Ministry of Defence (MOD), and other international partners.

The cubesats will provide a test platform for monitoring radio signals, GPS, and sophisticated imaging as the UK Space Agency works towards developing a more connected space communication system with its allies. In particular, the mission will help the MOD to better understand how the UK and its international partners can work together to create a more capable, flexible, and low-cost system for operating satellites and data processing.

“We’re putting the UK at the forefront of small satellite launch, providing world-leading capability for commercial customers and governments within a global market, opening new opportunities and inspiring the current and next generation of British space scientists, engineers, and entrepreneurs,” said Ian Annett, Deputy CEO at the UK Space Agency. “These satellites showcase the UK’s strengths in designing and building satellites.

“Being able to launch from the UK and across Europe for the first time will boost our satellite industry further, create high skilled jobs across the country and deliver a key ambition of the National Space Strategy.”

The cubesats will be fired into LEO on Virgin Orbit’s Launcher One rocket and operate around 550km above the earth. One cubesat is equipped with a hyperspectral imager, laser detector, and GPS receiver to capture higher definition images of the Earth, while the other includes two optical imaging cameras to offer a 180-degree view of the Earth’s surface and to observe the first cubesat.

“This is a great example of the power of international collaboration – a key tenet of our Defence Space Strategy,” said Air Vice Marshal Harv Smyth, Director Space at the MOD. “Prometheus-2 will deliver immense value to the UK MOD’s future space program and, thanks to our partners in the National Reconnaissance Office, this highly capable satellite will launch from UK soil this summer.

“I am hugely proud of what we have achieved together and this is just the beginning.”

Orbex unveils full-scale Prime prototype

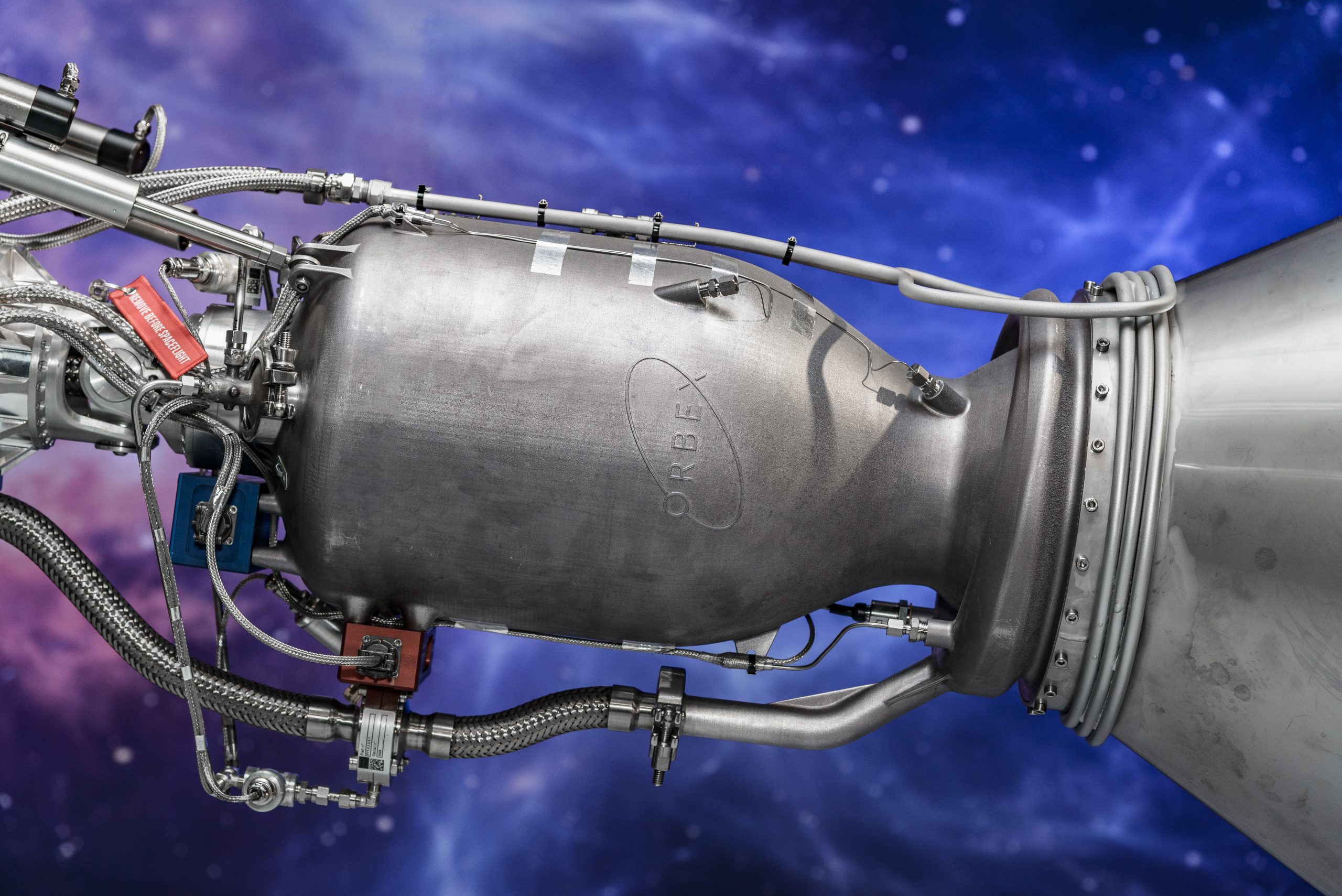

Meanwhile, Orbex has revealed the first full-scale prototype of its Prime micro-launcher rocket. Initially operating in stealth mode after its launch in 2015, the company burst onto the scene in 2018 after raising £30 million in funding. Orbex has previously worked with SLM Solutions on its 3D printed rocket engines, tipped to be the world’s largest in 2019.

In February last year, Orbex commissioned EOS Group company AMCM to build Europe’s largest industrial 3D printer to enable the rapid printing of rocket engines in-house. The multimillion-pound system will facilitate the printing of more than 35 single-piece large-scale rocket engine and main stage turbopump systems each year, which are critical parts of Orbex’s 19-meter-long Prime rocket.

The Prime rocket is fueled by renewable bio-propane fuel which reportedly reduces CO2 emissions by 90 percent compared to the kerosene-based fuels that power most current commercial rockets. The rocket is designed to be reusable so as to not leave any debris in orbit around the Earth and is equipped with a novel recovery and reusability system.

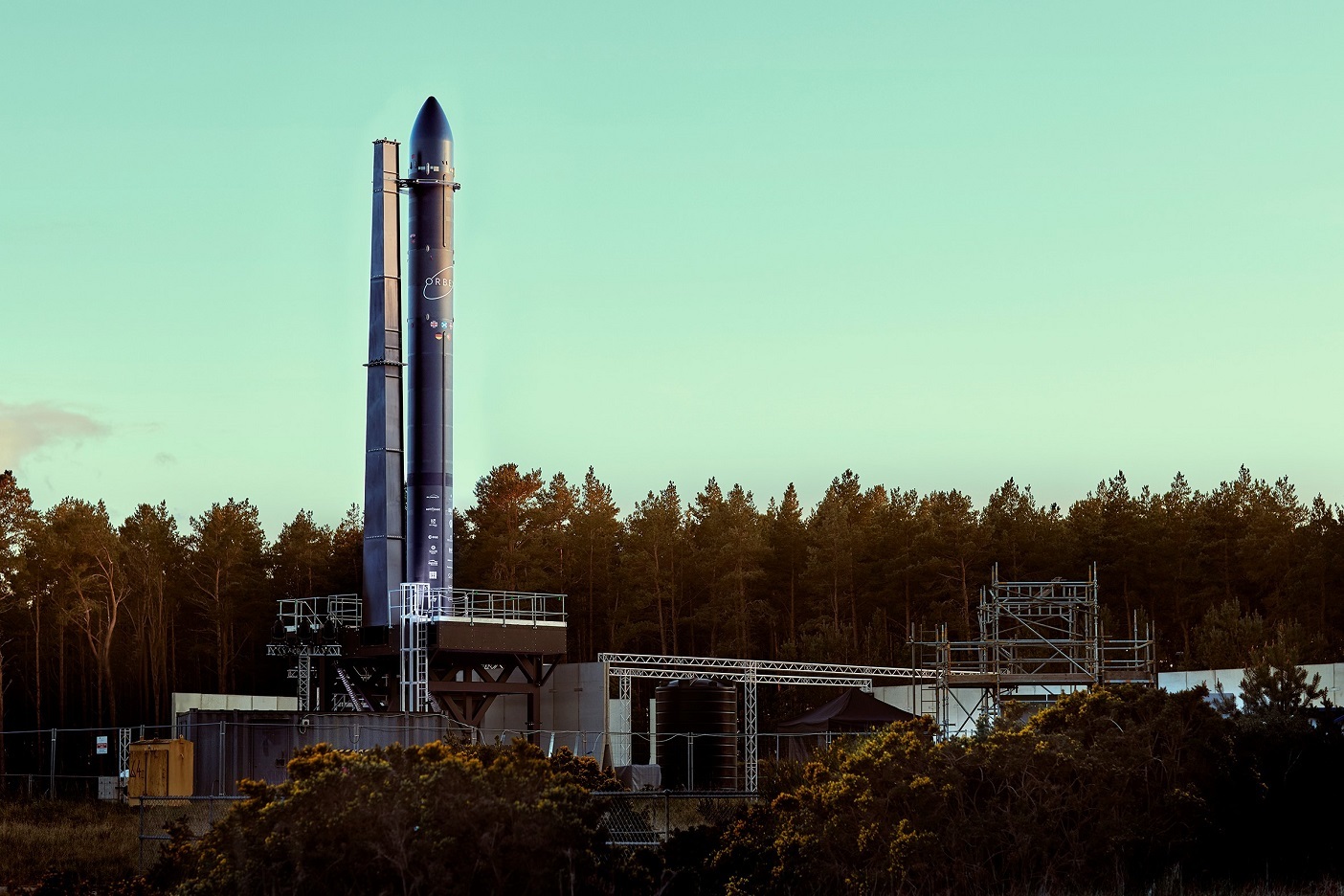

Now, Orbex has successfully integrated its first full-scale prototype Prime rocket onto the launch pad of its first test launch platform in Kinloss, Scotland. The firm will now look to conduct integrated testing, including ‘dress rehearsals’ of rocket launches and the development and optimization of launch procedures.

“This is a major milestone for Orbex and highlights just how far along our development path we now are,” said Chris Larmour, CEO of Orbex. “From the outside, it might look like an ordinary rocket, but on the inside, Prime is unlike anything else.

“To deliver the performance and environmental sustainability we wanted from a 21st century rocket we had to innovate in a wide number of areas – low carbon fuels, fully 3D printed rocket engines, very lightweight fuel tanks, and a novel, low-mass reusability technology.”

The Prime rocket will officially launch from Space Hub Sutherland, a new spaceport under development on the North Coast of Scotland. Space Hub Sutherland was the first vertical spaceport to receive planning permission in the UK back in August 2020.

“We are on the cusp of a historic moment, with Orbex playing a leading role in generating a brand-new launch capability in the UK, while creating opportunities for people and businesses across the country,” said Annett. “I can’t wait to see Prime lift off from Space Hub Sutherland.”

The UK’s thriving space scene

Employing some 47,000 people, the UK’s space sector currently generates an income of £16.5 billion. The UK government’s National Space Strategy is seeking to make the UK the leading European country to offer small satellite manufacturers a direct end-to-end route to launch, while simultaneously creating skilled jobs local to UK spaceports.

Space Hub Sutherland is one of seven potential spaceport sites across the UK, and once complete is expected to generate more than 600 jobs in the surrounding region.

“This is a hugely exciting time for the UK space and satellite sector as we count down to the first satellite launches from UK spaceports later this summer,” said Science Minister George Freeman. “Orbex Prime is a remarkable feat of engineering from a British rocket company, pioneering more sustainable and innovative fuels that cut carbon emissions.

“It is also fantastic to see Moray-based Orbex creating more high-quality jobs, demonstrating the value of our thriving space sector to support emerging clusters of innovation to help level up the whole of the UK.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the Orbex Prime rocket prototype on its launch pad. Photo via Orbex.