British aerospace firm Orbex has tasked AMCM, an EOS Group company that builds custom additive manufacturing machines, with building the largest industrial 3D printer in Europe to enable Orbex to rapidly print rocket engines in-house.

The multimillion-pound deal will see AMCM deliver a complete printing suite with post-processing machinery and ‘machine vision’ systems that will facilitate the printing of more than 35 large-scale rocket engine and main stage turbopump systems every year. These components will be critical parts of Orbex’s 19-meter long “microlauncher” rocket, designed to deliver small satellites into polar orbits around the earth.

“Although our rocket engines and other critical systems are already quite mature after years of testing a large-scale in-house 3D printing system like this gives us far greater speed and agility as we ramp up production,” said Chris Larmour, CEO of Orbex. “It means we can continue to iterate and drive up performance even further. Longer term, as we get ready for multiple launches per year, it will give us greater control over our costs and supply chain.”

Orbex’s Prime rocket

Orbex is planning to launch its Prime launch vehicle at its spaceport on the A’Mhoine peninsula in Sutherland in the Scottish Highlands, which was granted planning permission in August 2020. With Construction due to begin this year, the A’Mhoine site is currently the only UK spaceport to receive planning permission and will commence its first orbital launch in 2022.

The Prime rocket is fueled by a clean-burning, renewable fuel, bio-propane, which reduces CO2 emissions by 90 percent compared to the kerosene-based fuels used by most commercial rockets. Designed to be re-usable, the rocket will not leave any debris in orbit around the earth once launched, and features a novel recovery and reusability system.

Orbex Initially operated in stealth mode for several years after its launch in 2015 as it worked on launching a series of commercial CubeSats into orbit. The company burst onto the scene in 2018 after announcing it had raised £30 million ($40 million) in funding. Orbex has previously worked with German metal 3D printer manufacturer SLM Solutions on its 3D printed rocket engines, which were tipped to be the “world’s largest” in 2019.

Large-scale rocket part printing

Over several months, Orbex has carried out a series of trials with AMCM to print a range of large-scale rocket components as it looks to scale up its production capabilities for launches.

“After exhaustive trials, the results we’ve seen from AMCM were very successful and we’re confident that we’ve made the right choice of partner,” Larmour confirmed.

AMCM will custom-build and install what the companies claim to be the largest industrial 3D printer in Europe at Orbex’s facility, which will be expanded by 1,000 square meters in order to accommodate the machinery. Included in the multimillion-pound 3D printing system will be post-processing machines and ‘Machine Vision’ systems, which will provide automatic imaging-based inspection of the printed rocket components.

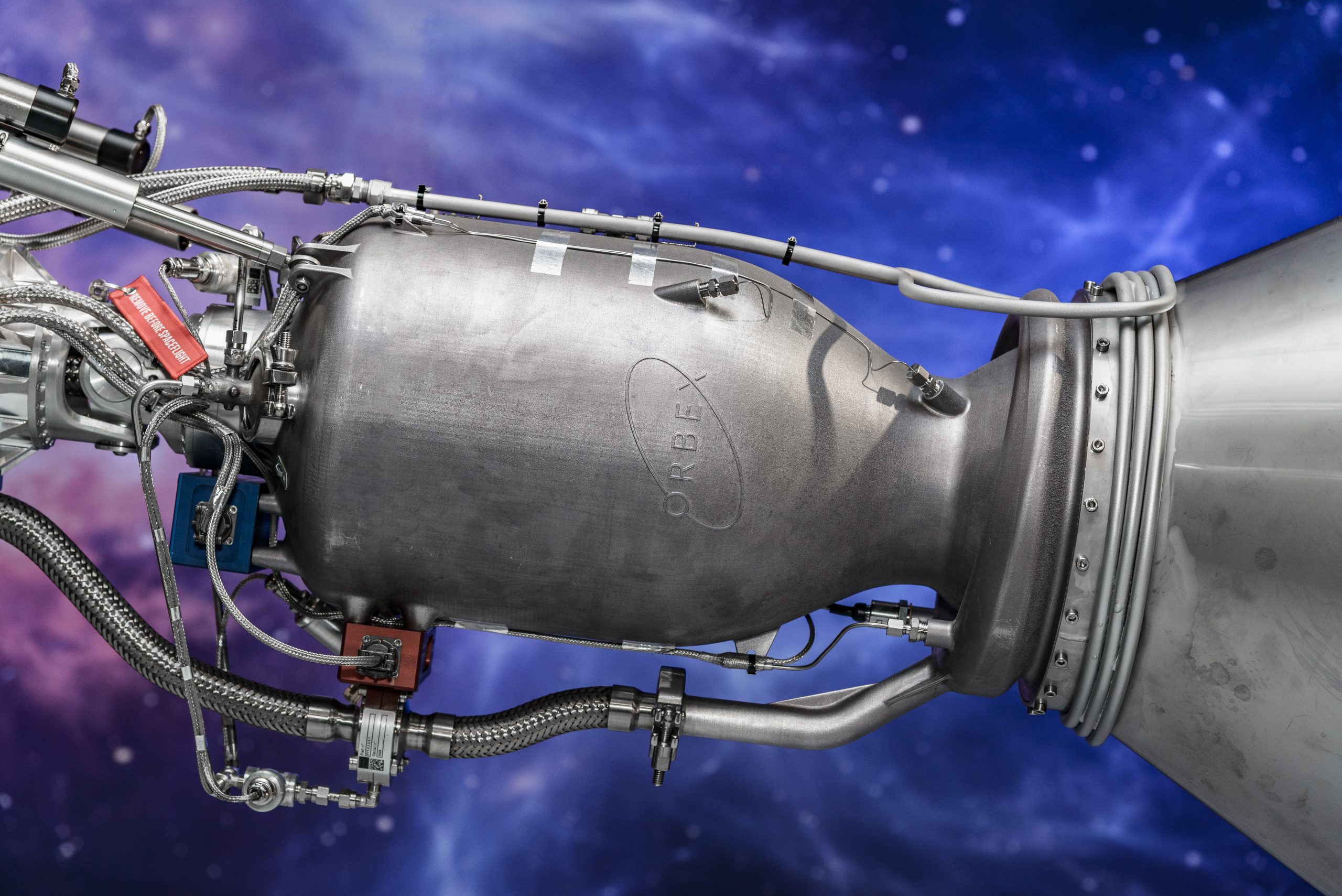

In order to eliminate weaknesses that can arise from joining and welding components together, Orbex’s rocket engine parts will be printed in a single piece. The components will be printed using a custom blend of metals, including titanium and aluminum, to ensure the system will be both lightweight and durable enough to withstand the extreme temperatures and pressures of spaceflight.

“Investing in a large-scale 3D printing system like this says a lot about Orbex’s ambition in the European flight sector,” said Martin Bullemer, Managing Director of AMCM. “If they are to lead the European market, they need the production reliability and speed that a large-scale 3D printing system like this will give them. And although this is a major purchase, it will allow for significant cost control for Orbex in the years to come.”

Orbex estimates the new printing system will deliver more than 35 rocket engines and turbopump systems each year and, as the first to launch from the new A’Mhoine Space Hub, it could become the first to ever successfully fire a commercial rocket into orbit from British soil.

Advancements in commercial 3D printed rockets

Additive manufacturing technologies have been used in the development and production of commercial aerospace rockets for some time, and this is becoming an increasingly competitive field for private aerospace companies.

One company which has been at the forefront of this sector is rocket-building firm Relativity Space, which has the ultimate goal of producing “the world’s first fully 3D printed rocket.” After securing a new headquarters in the hub of the aerospace community in Long Beach, California, the company was tasked with 3D printing projectiles for an upcoming experimental NASA mission. Relativity Space has since secured another contract with NASA to launch several small satellites into Low Earth Orbit via its Terran 1 rockets in 2022.

Elsewhere, California-based aerospace company Rocket Lab’s 3D printed Electron Rocket entered final testing ahead of the firm’s upcoming mission with the U.S. Space Force, and U.S. start-up Rocket Crafters has concluded testing of its Comet Series hybrid 3D printed rocket engine.

Earlier this month, Indian space startup Agnikul successfully test-fired its semi-cryogenic rocket engine, which it claims is the first to be 3D printed as a single component in one run. The engine was produced at just a tenth of the cost of conventional manufacturing means and can be printed in less than four days.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Orbex’s Stage 2 Prime rocket. Image via Orbex.