Private US aerospace Launcher has successfully completed another testing milestone for its 3D printed E-2 liquid rocket engine at NASA Stennis Space Center.

The firm’s rocket engine achieved nominal thrust, pressure, and oxidizer/fuel mixture ration for the first time, and was reportedly in “perfect condition” after 40 seconds of test firing.

Launcher will now turn its attention to increasing the rocket’s combustion (C*) efficiency from 90 percent to its 98 percent target during further tests in May.

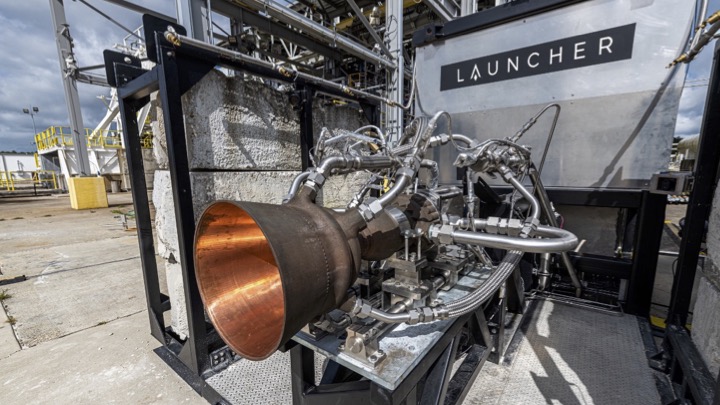

Launcher’s E-2 rocket engine

Launcher was founded in 2017 was the aim of creating efficient, cost-effective rockets capable of delivering small satellites to space. The firm began developing 3D printed components to enhance the performance of its E-2 engine after receiving a $1.5 million US Space Force contract in 2019.

The E-2 is a closed-cycle 3D printed high-performance liquid rocket engine that will power the firm’s Launcher Light launch vehicle, scheduled for launch in 2024. Once completed, a single E-2 engine will be capable of boosting the Launcher Light to low Earth orbit (LEO) with a 150kg payload.

So far, the engine contains multiple 3D printed components, which are 3D printed in high-performance copper alloys in order to require less propellant to get into orbit. The engine is comprised of a combustion chamber printed in a single piece that is reportedly the largest part of its kind at 860mm tall, and a 3D printed engine injector.

Launcher has worked with EOS Group company AMCM to develop a custom large-format 3D printer for produce its engine components, while its combustion chamber is produced using AMCM’s M4K machine. The firm conducted the first full-scale test-fire of its E-2 engine injector and combustion chamber in 2020, followed by a series of tests of its 3D printed liquid oxygen (LOX) turbopump, 3D printed on a Velo3D Sapphire printer.

In August last year, Launcher completed a successful thrust chamber assembly hot fire test at NASA’s Stennis Space Center and a few months later purchased a second Sapphire 3D printing system from Velo3D capable of printing titanium, with which the firm will begin printing orbiter pressure vessels for the E-2.

Most recently, Launcher selected post-processing systems manufacturer Solukon as its preferred supplier for powder removal systems. The firm has integrated Solukon’s SFM-AT1000-S depowdering machine to post-process its 3D printed rocket parts and further automate its production process.

Achieving full thrust

Launcher has now reached another testing milestone with its E-2 engine. The engine successfully demonstrated a full thrust of 10 metric tons during the test firing alongside achieving 100 bar of combustion pressure. The engine also saw the highest performance of oxidizer to fuel mixture ratio of 2.62 propellant mixture ratio for LOX at 100 bar of pressure.

After 40 seconds of total test firing time, the 3D printed copper alloy combustion chamber remained in “perfect” condition, demonstrating its reusability.

Going forwards, Launcher will test the E-2 again in early May with the same chamber and injector, although the components will be lightly reworked to remove all film cooling in order to further increase performance. The firm aims to increase C* efficiency from 90 percent achieved in its most recent test to 98 percent, which is its ultimate target.

The firm is also hoping to see its trademark blue Mach diamonds for the LOX/kerosene-based engine during the May tests, which it says would be a global first.

Regarding the development of its LOX turbopump, Launcher successfully tested the component in boost mode at 130 percent nominal flow. As a next step, the firm expects to demonstrate a full-duration, three-minute test of the turbopump in closed cycle configuration in Q4 2022.

Recent rocket testing achievements

While Launcher is making significant progress in the development of its E-2 rocket engine, other players in the sector are also making significant process with their own engines. Well-known names in the field like Rocket Lab, SpaceX, Orbex, and Relativity Space are all leveraging additive manufacturing as the race to space continues to ramp up, while several newcomers are also joining the contest.

In the last few months alone, propulsion system manufacturer Aerojet Rocketdyne has successfully tested a scramjet system as part of a US hypersonic missile research project. By 3D printing the engine’s drive system, the company says it can construct the component using 95 percent fewer parts than were needed to build its previous iteration.

Elsewhere, space technology 3D printing firm X-Bow Launch Systems exited stealth mode last month with a lineup of small launch vehicles suitable for both orbital and suborbital launches, while Chinese start-up SpaceTai announced plans for the first suborbital test flight of its 3D printed rocket to take place next year.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows Launcher E-2 thrust chamber assembly on its test stand at NASA Stennis Space Center. Photo via Launcher/John Kraus Photography.