Space technology 3D printing firm X-Bow Systems has closed a $27 million Series A funding round, securing the support of defense contractor Lockheed Martin.

The funding round closes ahead of the firm’s static fire test of its Ballesta solid rocket motor, which will reportedly be the first large-diameter scale motor designed and tested by a non-legacy systems integrator supplier in over three decades.

“We are proud of the support we have received from our investors and appreciate the confidence they signal in X-Bow’s team, breakthrough technology and innovative approach to solid rocket motor development,” said Jason Hundley, X-Bow CEO and Founder.

“Raising a strong round with these high caliber investors allows us to increase our rapid growth and accelerate our plans to disrupt a critical industry.”

3D printing solid fuel rocket engines

Originally founded in 2016, X-Bow Systems specializes in the development of 3D printed solid fuels and rocket motors. Solid fuel rocket engines rely on propellants that come in solid form, and are often used for military applications thanks to their simplicity and robustness.

X-Bow Systems exited stealth mode last month, having created a lineup of small launch vehicles suitable for orbital and suborbital launches. The company has already secured several contracts with US government organizations including the Air force Research Lab, AFWERX, Los Alamos National Lab, Sandia National Lab, and the Defense Research Projects Agency (DARPA).

X-Bow Systems claims its launch vehicles are both more efficient and more cost-effective than traditional rocket engines. Over the last few years, the firm has amassed a growing product line of 3D printed rocket engines, additively manufacture propellants, and end-to-end launch services for its government and commercial clients.

X-Bow’s Series A funding round

X-Bow systems will use the $27 million raised from its Series A funding round to advance its patent-pending additive manufacturing technology for solid rocket energetics and expand its solid rocket motor product portfolio. The new capital comes at a time of significant growth for the firm as it looks to bring its large-scale motor designs and modular boost vehicle architectures to its existing and new customers.

The company will also use the funds to further improve its customer support, grow its teams, and invest in its next generation of product offerings.

The funding round was co-led by Crosslink Capital and Razor’s Edge Ventures, and saw participation from Lockheed Martin Ventures and Broom Ventures. The support of Lockheed Martin is significant for X-Bow Systems due to the firm’s standing as a global technology leader in aerospace, space, and security.

Lockheed Martin has long sought to “print the path to Mars”, and has previously deployed 3D printing to fabricate 3D printed domes for high-pressure fuel tanks onboard satellites and invested in a state-of-the-art satellite production facility. The firm’s 3D printed parts have traveled as far as Jupiter and are currently used in NASA’s Orion crewed spacecraft, military satellites, and missiles.

“X-Bow has a great combination of experienced leadership and a truly innovative additive manufacturing technology for energetics,” said Matt Bigge, Crosslink Capital Partner. “They are the much-needed changemaker poised to disrupt the energetics market with its disruptive technologies.

“Crosslink invested in X-Bow because of its ability to catalyze a critical evolution in the national security, defense and commercial space technology markets.”

The funding round has closed ahead of the planned test fire and launch of X-Bow systems’ 32” diameter Ballesta solid rocket motor, which will take place at White Sands Missile Range in New Mexico.

“The X-Bow team brings a unique perspective and clear vision of the gaps within the traditional ecosystem of solid rocket motor manufacturers,” said Mark Spoto, Co-founder and Managing Partner of Razor’s Edge Ventures. “The company’s proprietary additive manufacturing approach to solid rocket energetics, motors, and architectures will, for the first time, enable rapid, agile, cost-effective solutions to be brought to a market that has always thought about product development in terms of years of development time and tens or hundreds of millions of dollars per product.

“We invest in great management teams with differentiated products that solve large, difficult problems across both national security and the commercial enterprise markets and are extremely excited to partner with X-Bow’s team to help accelerate their growth and product expansion.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

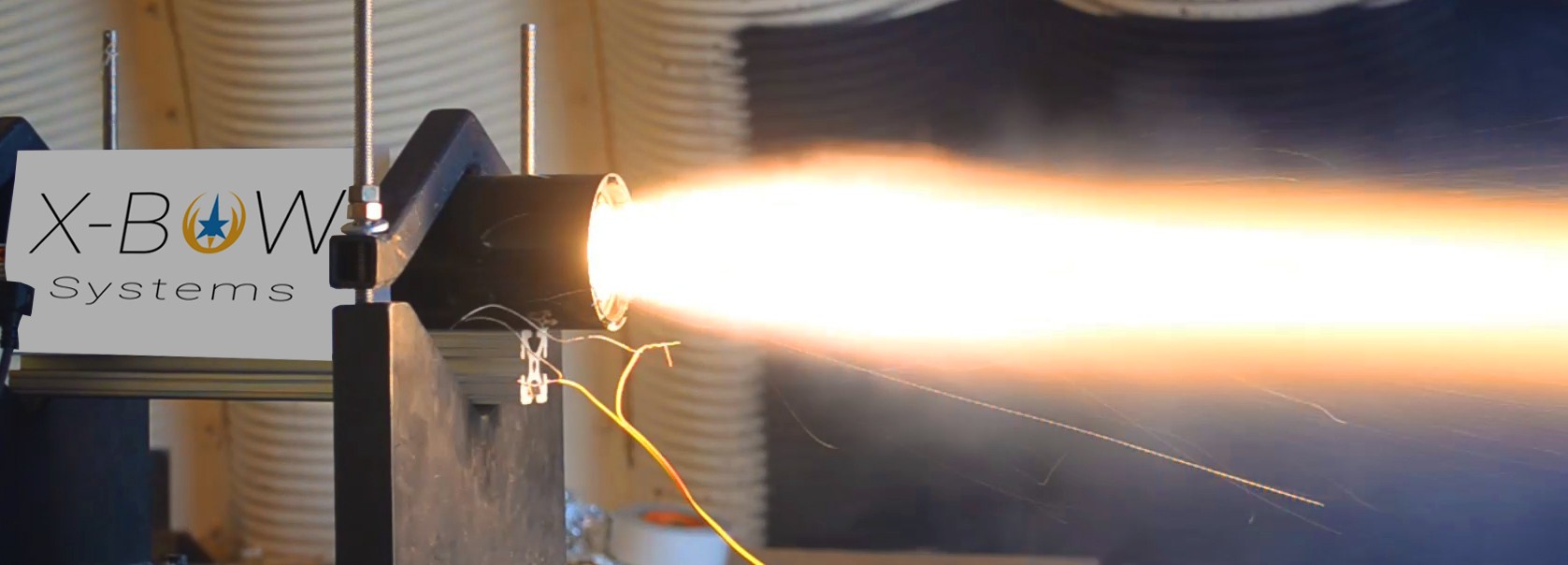

Featured image shows X-Bow testing one of its solid fuel rocket engines. Photo via X-Bow.