Propulsion system manufacturer Aerojet Rocketdyne has received its largest RL10 contract to date from space launch firm United Launch Alliance (ULA).

As part of the deal, Aerojet Rocketdyne will deliver 116 of its partially-3D printed RL10C-X engines to ULA for use in the latter’s new heavy-lift Vulcan Centaur rockets.

ULA will use its new 3D printed engines to support the launch of e-commerce giant Amazon’s upcoming Kuiper satellite constellation. Competing with SpaceX’s Starlink, the initiative is set to increase global broadband access via a constellation of 3,236 satellites in low Earth orbit (LEO). Project Kuiper is said to be the world’s largest commercial launch contract in history, with Amazon awarding up to 83 launches over a five-year period.

“The RL10 is the highest performance upper-stage rocket engine flying today,” said Tory Bruno, ULA President and CEO. “We’re proud to be launching the Kuiper constellation with the next generation of this incredibly reliable and high-performance engine.”

Sixty years of Aerojet Rocketdyne

Based in California, Aerojet Rocketdyne has built a name for itself by developing propulsion and energetics systems for both defense agencies and private enterprises. The company’s original rocket engine, the RL10, was first introduced in 1963. In the past 60 years, more than 500 RL10s have been launched into space and the engine currently powers the upper stages of ULA’s Delta IV and Atlas V rockets.

In order to streamline manufacturing, slash costs, and improve performance, Aerojet has started turning to 3D printing to produce some of the components in its rocket engines and strategic missile systems.

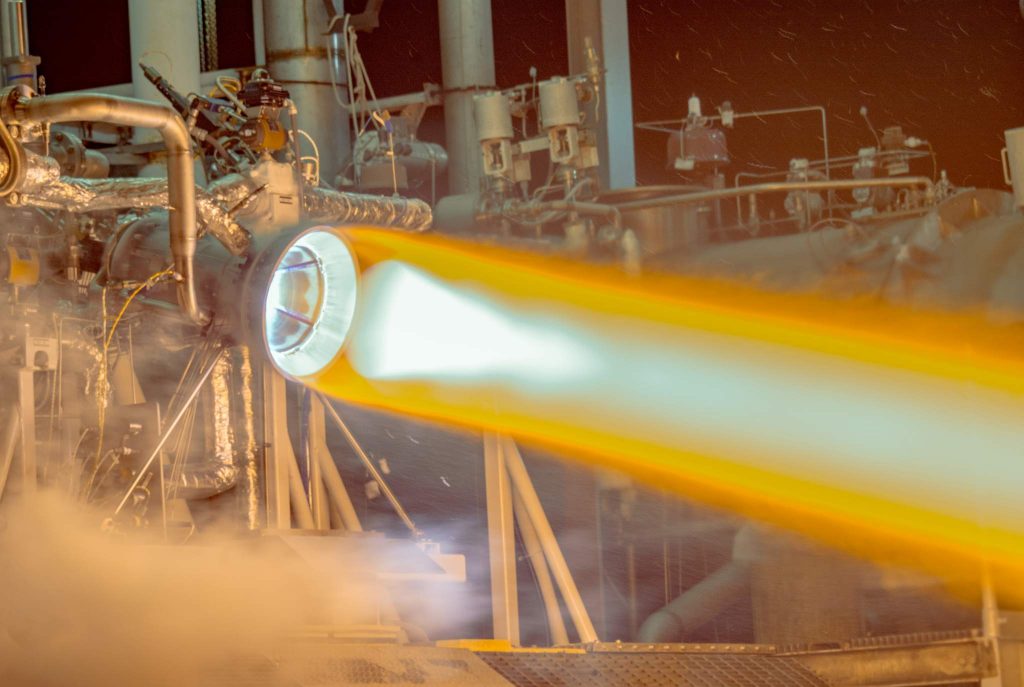

In 2017, Aerojet Rocketdyne announced the successful hot-fire testing of a 3D printed thrust chamber for its RL10 rocket engine. The component was 3D printed in copper using selective laser melting (SLM).

The RL10C-X, which is an upgraded version of the RL10, successfully passed NASA hot-fire testing procedures in May 2021. Featuring a set of critical 3D printed parts, the engine managed to demonstrate ignition and long-term durability within in-space simulations.

More recently, Aerojet Rocketdyne also used 3D printing to optimize a key component of its Reaction Control System (RCS) quad thruster with the help of nTopology’s engineering software. The component is now 67% lighter and helped reduce the overall production cost of the thruster by 66%.

The RL10C-X engine

Designed, manufactured, assembled, and tested at Aerojet’s West Palm Beach facility, the next-generation RL10C-X leverages a 3D printed injector and combustion chamber. The engine also comes equipped with a 94” monolithic carbon-carbon composite nozzle.

With a specific impulse (Isp) of 461 seconds, it’s one of the highest-performance rocket engines in the Aerojet Rocketdyne lineup. Isp is a measure of thrust per unit of propellant consumed per second.

“The RL10 engine is the nation’s premier upper-stage engine and a true workhorse in the industry,” said Eileen P. Drake, Aerojet Rocketdyne’s CEO and President. “With the RL10C-X, we’ve leveraged our industry-leading 3D-printing technology to significantly reduce the cost of the engine while at the same time increasing its performance to provide our customer with enhanced mission capability.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an artist’s rendering of the Vulcan Centaur rocket. Image via ULA.