The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

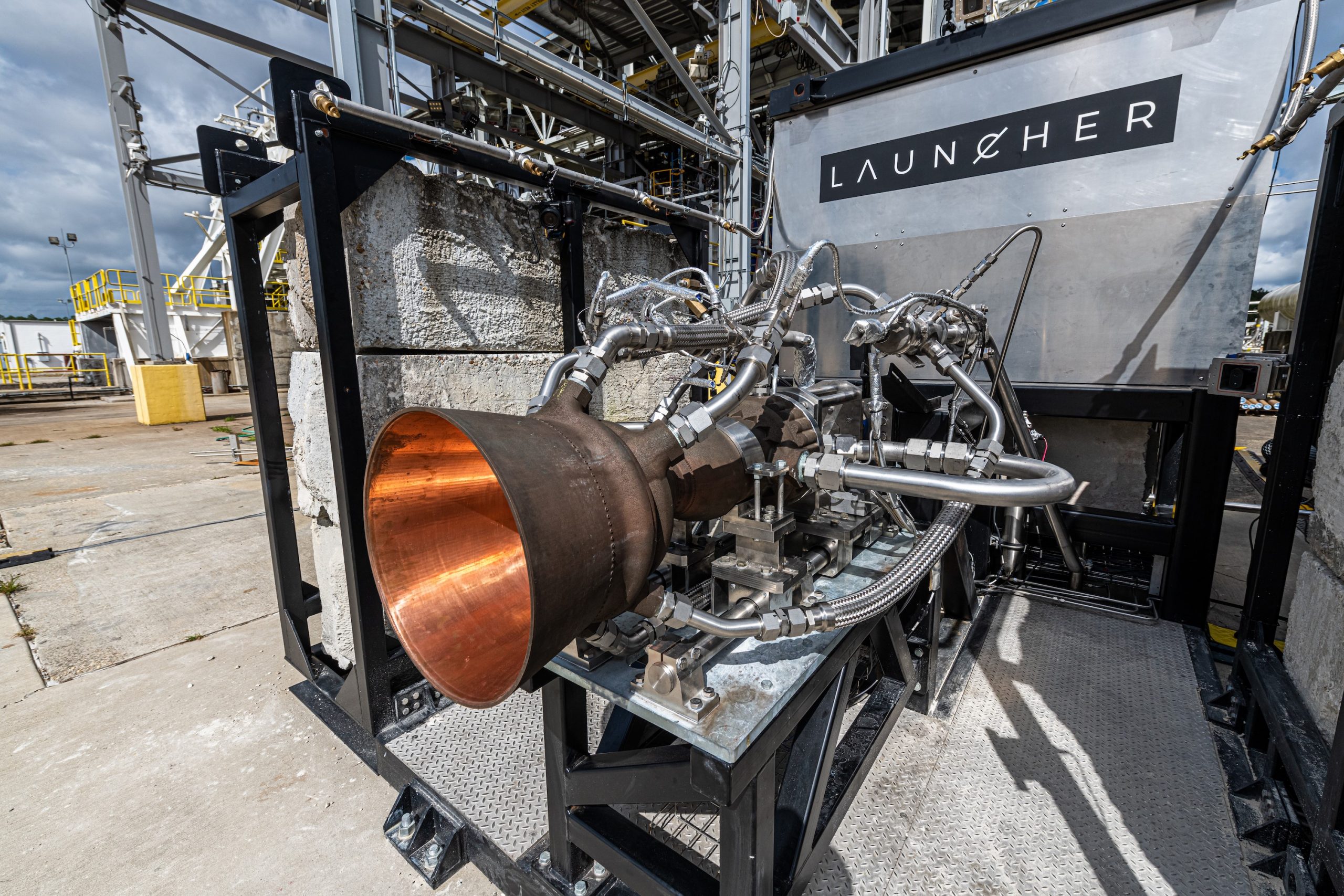

Private US aerospace firm Launcher has hit another milestone in the testing of its 3D printed E-2 rocket engine at NASA’s Stennis Space Center.

The company successfully completed a thrust chamber assembly hot fire test in August, following a string of testing achievements for its E-2 rocket engine at Stennis earlier this year. Launcher has also purchased a second Sapphire 3D printing system from 3DD printer OEM Velo3D capable of printing titanium, which it will leverage to begin printing orbiter pressure vessels for the engine.

“The opportunity to work with a world-class team and facility at Stennis has allowed us to achieve major milestones in the development of E-2,” said Andre Ivankovic, Lead Engineer at Launcher. “The Stennis team works hard to meet our testing needs, and the facility can provide us with large quantities of high-pressure gases and propellants, as well as a data acquisition system.

“These capabilities have been critical for us to achieve multiple test campaigns within the first year of becoming a commercial tenant.”

Optimizing rocket engines with 3D printing

Launcher was established in 2017 with the goal of creating efficient, optimal cost rockets capable of delivering small satellites to space. After receiving a $1.5 million Space Force contract in 2019, the firm began developing 3D printed components to upgrade the performance of its E-2 engine.

The E-2 engine is designed to produce 22,000 pounds of thrust at sea level using RP-1, a highly refined form of kerosene, and liquid oxygen as its propellants. The engine will power the company’s Launcher Light vehicle, which will be able to deliver payloads of up to 330 pounds to low-Earth orbit (LEO) by its first launch slated for 2024.

Among the components printed so far is a rocket combustion chamber, which was reportedly the largest part of its kind measuring 860mm tall, and 3D printed in a single piece. According to Launcher, the chamber will produce the largest thrust, yield the lowest propellant consumption, and offer the lower cost-per-pound of thrust in the small satellite launcher class.

Launcher’s E-2 engines are 3D printed in high-performance copper alloy and are designed to require less propellant to get to orbit. The company hopes this will enable the delivery of more satellite cargo per rocket and therefore allow it to offer a lower price than its competitors.

Testing with Stennis

The Stennis space center is the leading rocket propulsion test facility in the US, equipped with specialized infrastructure, cryogenic propellant, and high pressure gas facilities and laboratories. The center also provides advanced data-gathering technologies to its commercial customers, government partners, and academia.

Launcher decided to test its 3D printed rocket engines at Stennis due to its expertise and flexibility in testing both full-scale rocket engines and components.

“As we scaled from 1,000-lbf thrust liquid rocket engine tests at our own test site to 22,000-lbf thrust engines, we partnered with NASA Stennis due to the surprisingly low cost and incredible facilities we could leverage,” said Max Haot, Launcher Founder and CEO. “At the start, we were wondering if the government organization would be able to work at our startup speed and with our culture.

“Since then we have been shocked at how great and easy it has been to work with the NASA team – to the point we nicknamed Stennis E complex ‘rocket engine testing paradise.’”

In late August, Launcher successfully completed a five-second hot fire test for the rocket engine’s thrust chamber assembly at Stennis, following a string of testing achievements at the site. Back in October 2020, the firm conducted the first full-scale test-fire of its E-2 engine injector and combustion chamber, followed by a series of tests of its 3D printed liquid oxygen (LOX) turbopump, printed in partnership with Velo3D.

Over the next few weeks, Launcher plans to conduct longer duration tests of its thrust chamber assembly. The company plans to conduct full-duration, full-scale testing of its E-2 engine integrated with the 3D printed turbopump by the middle of next year.

“There’s sometimes a misconception that working with the government is expensive,” said David “Skip” Roberts, a NASA Senior Project Engineer overseeing the Launcher test partnership. “However, by choosing to test at Stennis, commercial tenants like Launcher can reduce testing risk, speed up their developmental process, and incur cost-savings.

“One of the main reasons Launcher decided to come to Stennis was because of our test infrastructure and ability of our High Pressure Gas Facility to deliver needed propellants and gases.”

Expanding the partnership with Velo3D

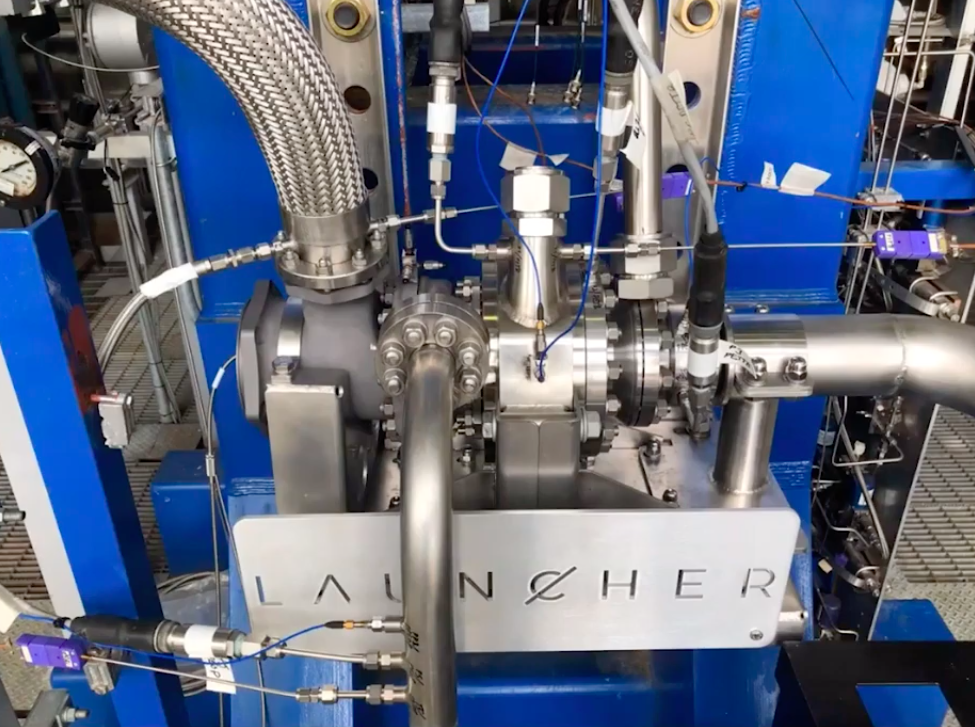

Launcher first partnered with Velo3D in May earlier this year to optimize the design of a performance-critical heritage LOX turbopump component within its E-2 rocket engine. Key components of the turbopump were 3D printed using a Velo3D Sapphire 3D printing system, including a pump outlet housing printed in Inconel, and a LOX pump inlet housing printed in aluminum.

The turbopump’s performance was evaluated at Stennis in a series of tests in April, including a liquid nitrogen cold flow test, made up of a total of seven tests lasting 211.2 seconds, and a liquid oxygen cold flow test consisting of eight tests for a combined 162.6 seconds.

Following the success of the tests, Launcher is now expanding its partnership with Velo3D through the purchase of a second Sapphire metal AM system capable of printing titanium. The partners will work together to 3D print the fuel pump and turbine housing parts of Launcher’s E-2 engine, with the second Sapphire machine used to 3D print the engine’s orbiter pressure vessels.

“Velo3D really delivered on our turbopump, including its 3D printed rotating impeller, all of which functioned perfectly the very first time at 30,000 rpm, using the first prototype,” said Haot. “Rocket engine turbopump parts typically require casting, forging and welding. Tooling required for these processes increases the cost of development and reduces flexibility between design iterations.

“The ability to 3D print our turbopump – including rotating Inconel shrouded impellers, thanks to Velo3D’s zero-degree technology makes it possible now at a lower cost and increased innovation through iteration between each prototype.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Launcher conducts a hot fire test for its 3D-printed Engine-2 rocket engine in the E Test Complex at NASA’s Stennis Space Center. Photo via Launcher/John Kraus Photography.