In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features aerospace installations, academic advances, military awards, material launches, an Olympian’s pistol grip and artisanal honeycomb-inspired sound-optimizing structures.

Read on for the most recent updates from Zortrax, Launcher, NIST, Orbital Composites, additive tectonics, ARMOR and more.

Farsoon and Launcher seal 3D printing deals

Starting this week with business news, Chinese 3D printer manufacturer Farsoon has announced its expansion into the Japanese market. The company has struck a deal with industrial equipment supplier Japan 3D Printer Co, that will see it distribute Farsoon’s SLS 3D printers across the country, potentially driving the technology’s uptake there in the process.

“With years of technology innovation and success in the global 3D Printing market, we are confident to offer the Japanese market our high-quality, truly open SLS solutions,” said Vince Zhao, Global Channel Manager (AMEA) of Farsoon. “Our partnership with Japan 3D Printer Co will help keep pushing the industrial application of Farsoon SLS technology.”

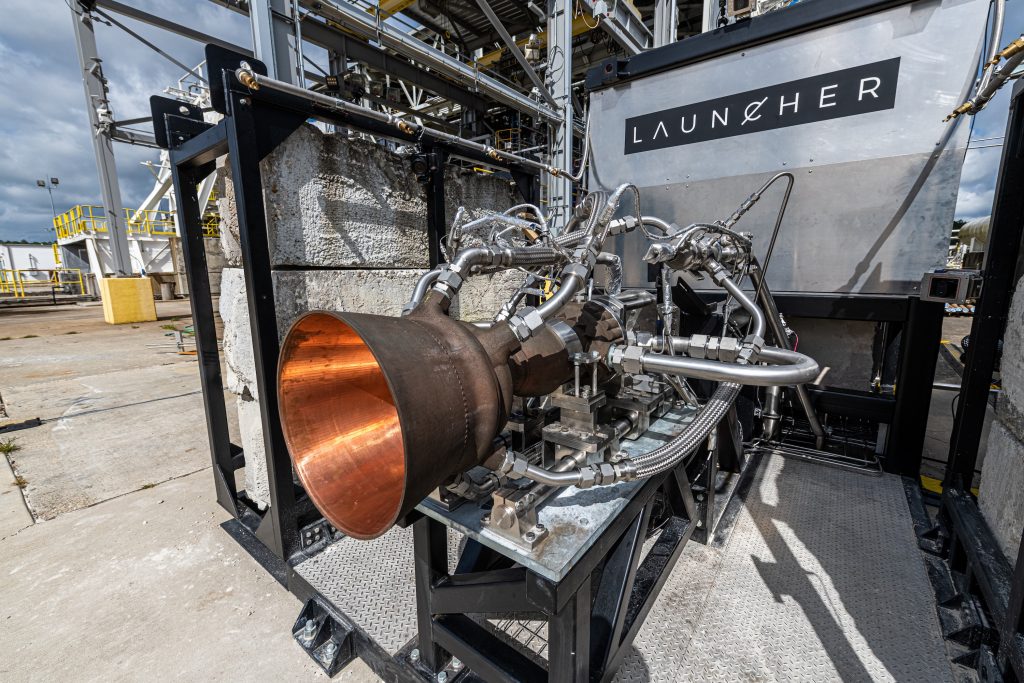

Private U.S-based Aerospace firm Launcher, meanwhile, has announced the acquisition of an M 4K AM 3D printer from EOS subsidiary AMCM. Leveraging its new system, Launcher has created the world’s largest single-part 3D printed copper alloy combustor, which will form part of its fully-printed ten ton-force E-2 rocket engine, and be used to launch small satellites into Low Earth Orbit (LEO).

Adopting additive manufacturing has already provided the firm with the flexibility needed to produce its engine combustion chamber as a single part, while incorporating an optimized cooling channel design. In fact, Launcher first requested that AMCM add copper support to its machine back in 2017, and it’s now leveraging the alloy to give its latest engine part enhanced thermally-conductive properties.

“AMCM’s flexibility and openness to customer requirements, both in machine building and process implementation, is remarkable,” said Max Haot, Founder and CEO of Launcher. “We look forward to continuing our partnership with AMCM as Launcher advances its mission to build and operate the market’s most efficient rockets delivering satellites to orbit.”

Academic updates from America Makes and UMD

On the academic front, U.S. national 3D printing accelerator America Makes has announced the completion of its Virtual Additive Manufacturing Educational Program. During the pilot project, which was backed by the National Institute of Standards and Technology (NIST), middle school students were invited to complete online courses in exchange for mini-badges.

Composed of eleven micro-learning modules, the program featured a series of short interactive lessons, with each designed to introduce students to a different essential element of 3D printing. Launched as part of America Makes’ wider ‘K-to-Grey Superhighway’ project, the web-based exercise was designed to help build the talent pipelines needed to fill the highly-skilled AM positions of the future.

“Exposing students to 3D printing must go well beyond the widget approach of a teacher downloading a file and giving it to the students to send to a 3D printer,” said Josh Cramer, America Makes’ Education & Workforce Development Director. “Students need much more depth than this to take advantage of future 3D printing career opportunities.”

In similarly educational news, automated 3D printing specialist Orbital Composites has announced the shipment of its modular Orbital S 3D printer to the University of Minnesota Duluth (UMD). Under the guidance of Dr. Gireesh Menta, the system is set to assist the UMD in its polymer and composite research, as well as providing students with hands-on experience of robotics and software programming.

The installation agreement marks a milestone for both parties, given that the UMD will now be able to incorporate the Orbital S into its curriculum and teach large-scale out-of-plane robotic 3D printing in practise, while it also represents Orbital Composites’ inaugural commercial shipment of a turnkey robotic system.

“Our team is very excited to receive the Orbital S,” said Dr Menta, “It not only enables us to conduct research in this exciting next-generation manufacturing technology, but also allows us to bring true interdisciplinary instruction to our classrooms. We expect this technology to improve UMD’s competitiveness in the AM field and result in job opportunities.”

SPEE3D wins National Defence Award

Metal 3D printer manufacturer SPEE3D has revealed that it’s set to take home this year’s edition of the ADMA Foundation’s Land Forces SME Innovation Award. The firm has been recognized for the ability of its high-speed machines to augment military supply chains, by providing them with on-demand part 3D printing capabilities.

The wider awards are designed to recognize Australian groups and individuals at the forefront of defensive innovations, and SPEE3D’s technology has been deployed twice during field tests over the last year, initially demonstrating portability in the outback, before being used as part of a more intensive two-week long trial in August 2020.

“SPEE3D is delighted to receive this award,” said Byron Kennedy, CEO of SPEE3D. “For defense, getting spare parts through regular supply chains to sustain and repair equipment can be difficult, and also very expensive. Our technology’s innovative qualities completely eliminate these issues, allowing the defense industry to take complete control of their own supply chain.”

Farsoon and BCN3D make material advances

In material news, Farsoon has partnered with German specialty chemicals company Evonik to develop novel powder formulations that unlock large-scale 3D printing applications at high temperatures. Using Farsoon’s ST252P and HT403P machines, the firms have already tested Evonik’s INFINAM PA 6005 P material, and they now have a further six new polyamide 6 powders in the pipeline.

“Close collaboration between material and machine manufacturers is essential to open up new 3D applications,” said Wolfgang Diekmann, Director of Innovation Management, AM at Evonik. “The results of our test series are clear: INFINAM PA 6005 P with its higher melting point of 215 °C, can not only be excellently processed on Farsoon’s ST252P and HT403P machines, but also reused. We have thus achieved a market-ready synergy.”

Spanish 3D printer manufacturer BCN3D, meanwhile, has launched its new Smart Cabinet. Designed to store filaments for the firm’s Epsilon W27 and W50 3D printers, the system uses smart drying technology to ensure that materials are kept at optimal humidity levels, providing users with protection against potential print failures or nozzle clogging.

Essentially the Smart Cabinet functions using humidity-absorbing alumina-based pellets and an absorption dryer method, which alternates between drying and regeneration cycles to maintain a dry environment around stored spools. As an added benefit, the machine also features an Uninterruptible Power Supply (UPS), that protects jobs by eliminating the risk of losing a print due to power outages.

“As 3D printers increase in terms of volume printing times also grow, so in industrial or lab contexts, where power outages or micro-cuts are quite frequent, the Smart Cabinet offers life-saving protection to reduce waste and improve efficiency,” said Eric Pallarés, CTO of BCN3D. “As a result, any customer aiming both with technical materials will benefit from this new product.”

Novel Olympic, acoustic and sealing applications

Finishing this week with novel AM applications, fastening and plastic technology specialist Hänssler has worked with ARMOR’s 3D printing subsidiary Kimya to design 300 sealing parts for one of its customers. The resulting components were designed to feature anti-electrostatic properties, enabling them to safely provide thermal protection between two assembled elements inside a machine.

Initially, Hänssler deployed Kimya’s ABS-ESD filament to 3D print low-volume batches of the complex parts, but they exhibited delamination and flow defects. In order to help its client overcome this barrier to production, ARMOR stepped in and helped develop a custom printing profile that eliminated part imperfections, enabling Hänssler to finally enter small-batch production runs.

“Our partnership with ARMOR has been very rewarding,” said Adrian Heinrich, Marketing Manager at Hänssler. “The teams have demonstrated their reliability and skills, especially in such a challenging project. They were also very responsive in designing a print profile to achieve the expected level of quality, and we were able to produce the parts on time.”

“We are confident that this type of cooperation will continue in the future and that we will use their 3D filaments for other projects.”

Elsewhere, German 3D printing bureau FIT AG subsidiary additive tectonics has collaborated with esteemed artist Peter Lang to create a sound-absorbing sculpture. Inspired by the nests of wasps and hornets, Lang worked with experts at the Rosenheim Technical University of Applied Sciences, to 3D print a series of small tubes into a ceiling-mounted sound element.

To recreate the artist’s hand-drawn sketches, a robotic arm-mounted FDM 3D printer was programmed using an algorithm that enabled its nozzles to traverse the entire object without ever crossing its own path. The resulting biocompatible plastic and beer adhesive-based piece, incorporates multicolored granules, different textures and a complex honeycomb-style geometry, to reportedly provide a ‘sound-optimizing’ effect.

Finally, multiple-time world shooting champion Céline Goberville has revealed that she will compete at this year’s European Shooting Championships using a Zortrax 3D printed pistol grip. Produced by Athletics 3D using an M300 Dual 3D printer, the ABS-based ergonomic grip has been customized through multiple design iterations, in order to make it perfectly fit Goberille’s specifications.

“When it comes to fitting a pistol grip, some athletes go for a heavily scientific approach. Me and my sister [who is also a competitive shooter], shoot on feel,” said Goberville. “The pistol is right when it feels right on the shooting range. This is why we tested multiple prototypes. I believe that technology is responsible for 30% to 40% of the final result in competitive 10-meter air pistol shooting.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our Facebook page.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of a photo of Peter Lang and his 3D printed acoustic artwork. Photo via FIT AG.