Interested in reading more about the year’s biggest 3D printing news? You can access our full 3D Printing Industry Review of the Year series here.

While the return of an in-person Rapid+TCT was undoubtedly one of the highlights of May 2022, the month also saw significant shifts in the 3D printing business world, material sustainability, textile production, and the automotive industry.

Read on to find out how the likes of Polymaker, Reiten Cheng, Braskem, BMW, Ferrari, Sauber, 6K, Morf3D, Dyndrite, Essentium, Formlabs and Stratasys helped these advances happen.

Mystery over F1 applications lifted

Though Formula 1 teams have long applied 3D printing up and down the grid, the competitive nature of the sport means these don’t always see the light of day. This changed somewhat with Pat Warner’s 3D Printing Industry interview, in which the Alpine stalwart revealed that up 70% of F1 wind tunnel-tested bodywork is additively manufactured.

Later in May, General Motors (GM) engineer Andrew Cunningham highlighted how Ferrari is using 3D printed parts to hold performance-tracking sensors in place, while EOS and Sauber signed up to a three-year partnership, through which the former agreed to 3D print everything from production aids to end-use race parts.

In more mainstream automotive 3D printing applications, BMW’s IDAM project was concluded successfully. The initiative saw BMW work with partners to establish two digitally-connected 3D printing production lines, capable of churning out 50,000 parts per year while operating independently without needing manual inputs.

Business shakeups across the industry

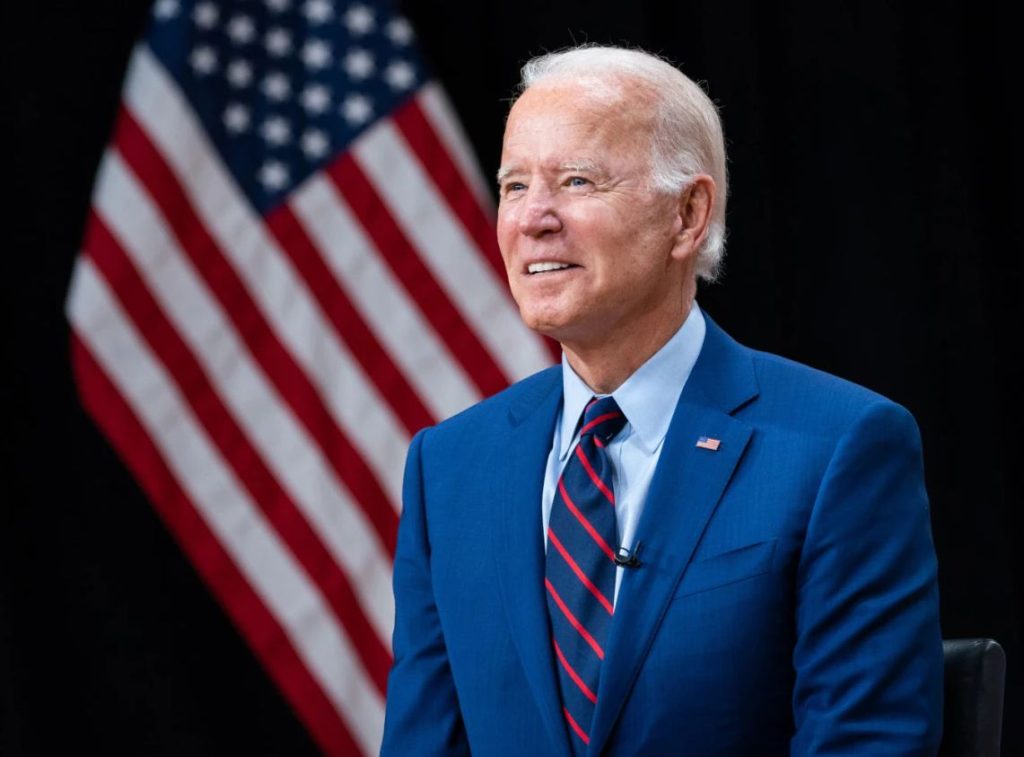

May was marked by one of the highest-profile 3D printing initiatives of the year: President Biden’s AM Forward program. The ongoing project, which has seen heavy hitters like GE Aviation, Honeywell, Lockheed Martin, Raytheon, and Siemens Energy commit to tapping more 3D printing firms for contracts, was later followed by a string of other significant business moves across the industry.

Following Essentium’s shelved SPAC merger, it was announced that the firm was developing a new blue-laser metal 3D printer. Set to be powered by NUBURU’s proprietary blue laser technology, it’s said the wire-fed machine will be capable of 3D printing parts with applications in critical industries such as automotive, aerospace, and defense.

After 6K raised $102 million in funding, in the first part of an initial investment worth up to $150 million, it committed to building on its powder and cathode production capacities. As part of 3D Printing Industry’s 6K facility tour later in the year, the company explained the key drivers behind its growth and the areas in which it planned to expand.

Material sustainability advances

Another interesting trend seen in May was the unveiling of several new eco-friendly material advances at once. While researchers at Bath University developed a means of using sugar to make PLA biodegradable, Reiten Cheng launched the Polyformer, a device capable of turning discarded plastic water bottles into functional 3D printing filaments.

This shift towards eco-friendly feedstocks was seen at Rapid+TCT as well, where Braskem released its first sustainable filaments. At the time, the firm said its range of bio-based ethylene vinyl acetate (EVA), recycled polyethylene (PE) and polypropylene (PP) materials reflected its ‘commitment to a more circular, carbon neutral future.’

Polymaker also exhibited a variety of its filaments at the show, which are now packed onto cardboard rather than disposable, environmentally damaging plastic spools. The firm’s efforts in this area later saw it nominated by readers within the Sustainability in Additive Manufacturing category of the 2022 3D Printing Industry Awards.

Textile 3D printing on the red carpet

It may not be the first application that comes to mind when readers think of 3D printing, but the technology continues to make progress in custom textile production. In May, fashion designer Iris van Herpen’s latest 3D printed gowns were worn at this year’s Met Gala by actress Dove Cameron, singer-songwriter Teyana Taylor, model and activist Winnie Harlow and Swedish actor Fredrik Robertsson.

The garments’ debuts were followed by a number of textile additive manufacturing advances across the year. Shortly afterwards, for instance, UK start-up Modern Synthesis raised $4.1 million towards its microbial textile platform. Designed to help the fashion sector lower its carbon footprint and reduce waste, the firm’s microbial weaving process enables materials to be ‘grown’ into shape over 10-14 days.

Rapid+TCT returns in Chicago

Last, but certainly not least, Rapid+TCT returned to strength in May 2022, where more than 400 exhibitors descended upon the venue to showcase their latest launches. Formlabs introduced two new resins at the show, while Morf3D and 6K unveiled plans to qualify metal powders for aerospace and automotive customers.

Elsewhere, Materialise introduced Magics 26, an updated version of its popular print preparation software, complete with native CAD-based workflow support. This newly-added functionality enabled users to modify and iterate on CAD files directly in Magics, something that wasn’t previously possible prior to the firm’s update.

In software, meanwhile, Dyndrite signed three new partnerships with 3D printer OEMs Azul 3D and Impossible Objects, as well as printhead technology provider Meteor Inkjet. Freemelt also debuted its Pixelmelt software, a process optimization tool designed to help Freemelt ONE users modify process parameters across several parts in a single build.

2022: 3D Printing Industry review of trends and news

2021: 3D Printing Industry review of trends and news

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows US President Joe Biden. Image via the White House.