UK-based biomaterials start-up Modern Synthesis has raised $4.1 million in seed funding to develop its microbial textile platform which could help the fashion sector to lower its carbon footprint and reduce waste.

Operating in much the same way as 3D bioprinting, the firm’s microbial weaving process is capable of creating a customizable biomaterial that grows over the course of 10-14 days to form objects of a desired shape. The company’s goal is to replace materials derived from animals and petrochemicals with its biodegradable alternative, having so far successfully produced and delivered a shoe upper to a key sportswear customer.

“What we’re trying to do is build this new class of materials that is more sustainable but also allows us to design and create in new ways, which is really exciting for the fashion industry,” Modern Synthesis Co-founder and CEO Jen Keane told AFN.

The microbial weaving process

Modern Synthesis’ platform is based on its patent-pending microbial weaving process, which leverages bacteria to ‘weave’ customizable biotextiles and composites. The technique uses bacteria to transform sugar from agricultural waste into nanocellulose, which is not only biodegradable but is also valued for its abundance and strength.

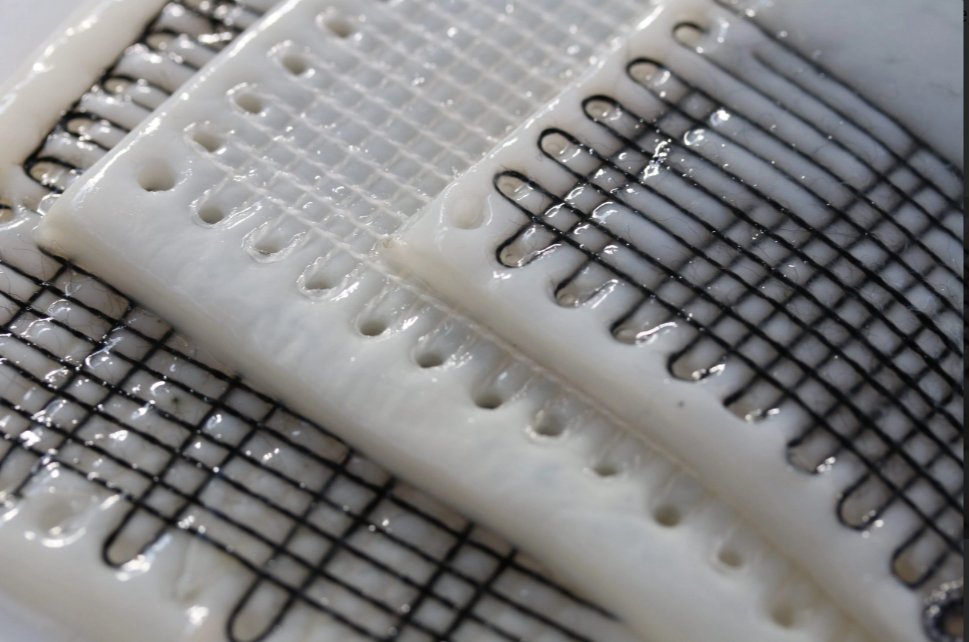

The process works by creating a scaffold and using robotics to place fibers around which the bacteria grow to form a strong, lightweight cellulose-based biomaterial with limitless customization potential.

Called k.rhaeticus, the bacteria in question is one of those often found in kombucha tea and which has previously been used to produce more sustainable 3D printable wood substitutes. Within the material, the bacteria act as ‘tiny weaving shuttles’ that leave a tiny trail of fibers in their wake similar to the waft-and-weft weaving technique. Once grown, the semi-transparent gel material is made up of a tightly packed mesh of fibers.

Modern Synthesis compares its microbial weaving process to 3D printing due to its ability to produce objects of a desired shape and size without waste, and its additive rather than subtractive nature.

A $4.1 million boost

The $4.1 million seed funding raised by Modern Synthesis will help the company to build on its microbial textile platform and build its pilot facility. Housing a lab, sampling, and pilot production capabilities, the planned site in London will enable the company to scale up the production of its materials.

The new facility is expected to be operational by Q3 2022, with additional funds from the round also being used to build the company’s team and increase its R&D activities.

The funding round saw participation from AgFunder, Collaborative Fund, Acequia Capital, Petri Bio, Ponderosa Ventures, Possible Ventures, IMO Ventures, Taihill Venture, Parley for the Oceans, Climate Capital Collective, and the former CEO of designer footwear brand Jimmy Choo, Pierre Dennis.

According to Keane, the goal is to get Modern Synthesis’ materials out into the world as “quickly, widely, and responsibly” as possible. The ultimate goal is to replace many of the animal and petrochemical-based materials currently used within the fashion industry, making the sector as a whole more sustainable in line with the principles of a circular economy.

“At the end of the day, we’re trying to build a circular manufacturing system with these microbes,” Keane told AFN. “That enables us to leverage agricultural waste and use the microbes as manufacturing units and transfer them into more viable materials.

“On the flip side, we see the opportunity to have new-class materials that are fully cellulosic, so we can recycle them back into silos and recycling streams.”

Printing cellulose-based materials

Cellulose has garnered much attention within the 3D printing space due to its potential as a natural sustainable, and versatile replacement for a range of synthetic materials. In fact, cellulose has been utilized in the formation of more sustainable 3D printing feedstock for several years already.

In March last year, the EU-funded NOVUM project was initiated to 3D print components from cellulose-based materials for use in the automotive, marine, and electrical insulation sectors. The aim of the project is to address global awareness around resource sufficiency, climate change, and the circular economy by exploring cellulose as a substitute for fossil-based materials.

Elsewhere, Oak Ridge National Laboratory (ORNL) and the University of Maine are creating bio-based materials for large-scale 3D printing, including the use of cellulose nanofiber, while the University of Bristol and the University of Bath have explored the potential of 4D printing cellulose to produce structures that transform in response to water.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows a shoe upper fabricated via the microbial weaving process. Photo via Tom Mannion/Modern Synthesis.