Oak Ridge National Laboratory (ORNL), Tennessee, and the University of Maine (UMaine) have been granted $20 million in U.S. federal funding to create bio-based 3D material for large-scale additive manufacturing.

In the past three years alone, Maine has witnessed the closure of several paper mills, including a Madison Paper Industries facility which closed down in May 2016 costing 214 jobs. Using locally sourced wood as a base for the material, the hope is that this project will assist the declining forest products industry in the state. The initiative also hopes to foster a new generation of bio-based 3D printable materials that can be used to make boats, turbine blades, shelters and construction materials.

Investing in wood based materials

ORNL and UMaine’s new program, funded by the Department of Energy’s (DOE) Advanced Manufacturing Office, was officially announced in Washington D.C. last week. At launch it was supported by representatives from both partners, as well as three U.S. Senators, Susan Collins, Lamar Alexander and Angus King. Daniel Simmons, the U.S. DOE assistant secretary for energy efficiency and renewable energy was also present.

Sen. Collins, who is Senior United States Senator for Maine and an advocate for the paper mill industry, said, “This exciting initiative is a win-win that will bolster the cutting-edge research performed at the University of Maine as well as support job creation in our state.”

The research will be conducted at UMaine’s Advanced Structures and Composites Center housed in a 100,000 ft laboratory with more than 150 full and part time employees. Together, ORNL and UMaine scientists will investigate several areas relevant to the new wood based feedstock, including cellulose nanofiber (CNF) production, drying, compounding with thermoplastics, multi-scale modeling and sustainability life-cycle analysis. This will culminate in the manufacture of a boat mold using ORNL’s Big Area Additive Manufacturing machine (BAAM).

The power of nanocellulose

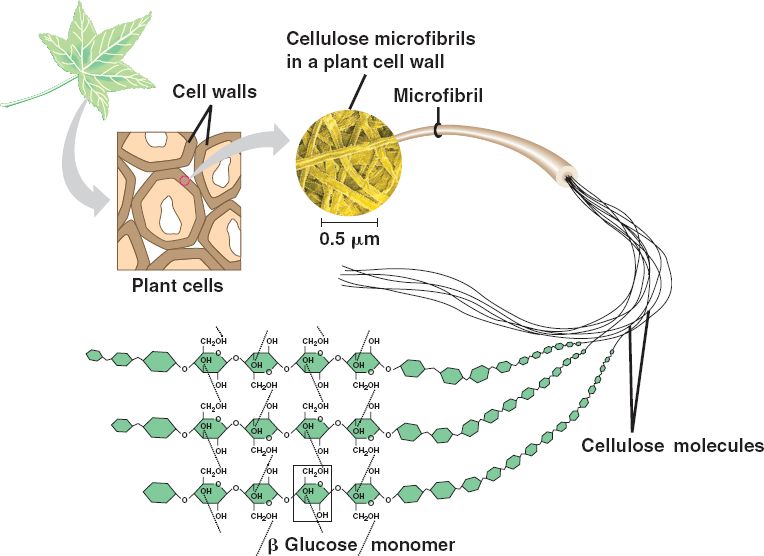

The base material used to make ORNL and UMaine’s new feedstock is nanocellulose. Developed in the late 1970s at the ITT Rayonier Labs in New Jersey nanocellulose is a fibrous, crystalline form of cellulose – the primary building block in the cell walls of green plants. The organic material has a tensile strength similar to that of aluminium, it is also electrically-conductive and non-toxic. More significantly, the raw material it originates from – cellulose – is the most abundant polymer on Earth.

Due to its high strength, biological and renewable potential, nanocellulose has been used in the fabrication of smart-dressings that heal and monitor skin wounds, as well as wood-based filaments for desktop 3D pritners. One of the features that makes the DOE funded project significant is its plan to produce large scale objects using a nanocellulose-based material.

Making a strong, universal bioplastic

Habib Dagher is executive director of UMaine’s Advanced Structures and Composites Center. According to Dagher the end material of this project could contain up to 50% cellulose fiber. Going into more detail about the filament composition he said “The material is nanocellulose, basically a tree ground up to its nano structure. These materials have properties similar to metals. We are taking those and putting them in bioplastics so we can make very strong plastics that we can make almost anything with.”

As the largest DOE science and energy laboratory, ORNL will be able to bring significant resources and expertise to the program. ORNL is well placed to assist with this particular project after setting a world record for the largest solid object ever 3D printed with its BAAM, as well as its experience creating reinforced composite FFF filament with lignin, the essential structural tissue of tree bark and wood.

Prior research at UMaine’s Advanced Structures and Composites Center, includes the development of nano and micro-cellulose reinforced thermoplastic composites for 3D printing, and a $500,000 award in October 2018 for developing ways to 3D printing large scale boat structures.

In October of this year ORNL’s BAAM 3D printer will be installed at UMaine, and will begin fabricating a boat mold using the bio-based feedstock

Vote for your 3D Printing Innovation of the Year in the 2019 3D Printing Industry Awards.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook. Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows UMaine Advanced Structures and Composites Center students and staff lift a boat roof from a mold 3D printed with a new biomaterial, nanocellulose reinforced polylactic acid (PLA). Image via the University of Maine.