Interested in reading more about the year’s biggest 3D printing news? You can access our full 3D Printing Industry Review of the Year series here.

In many ways, August was a month in which year-long 3D printing trends persisted. More firms went public via mergers with Special Purpose Acquisition Companies (SPACs), major manufacturers joined the AM Forward program, and high-end automotive and sustainability-focused applications continued to thrive.

While 3D printing implants won’t be news to regular readers, August unveiled several new designs, some commencing human trials.

Read on for more from key industry players like Stratasys, NUBURU, Shapeways, Boeing, Northrop Gruman, Divergent Technologies, Lithoz, BellaSeno, and more.

SPAC merger trend resurfaces

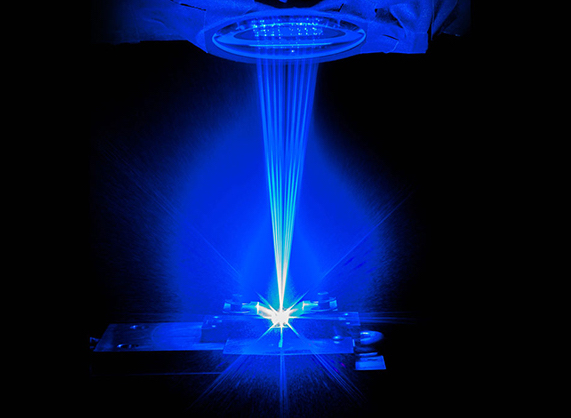

Through the first half of 2022, it had appeared that 3D printing’s SPAC merger trend was stalling, then NUBURU announced a $350 million SPAC merger. Set to be wrapped up in early 2023, the deal will see the firm merge with Tailwind Acquisition to form a $350 million enterprise with an estimated $434 million in funding.

In regulatory news, Shapeways was hit with a non-compliance notice from the New York Stock Exchange (NYSE) after failing to meet the 30-day average closing price requirement at a minimum one-dollar share price. Shapeways’ SPAC merger with Galileo Acquisition, which was concluded in September 2021, saw the company raise significant funding towards its expansion. However, it soon became clear that the firm wouldn’t reach its revenue forecast of $250 million by FY 2024, and its shares dipped to the point that it was threatened by the NYSE with delisting.

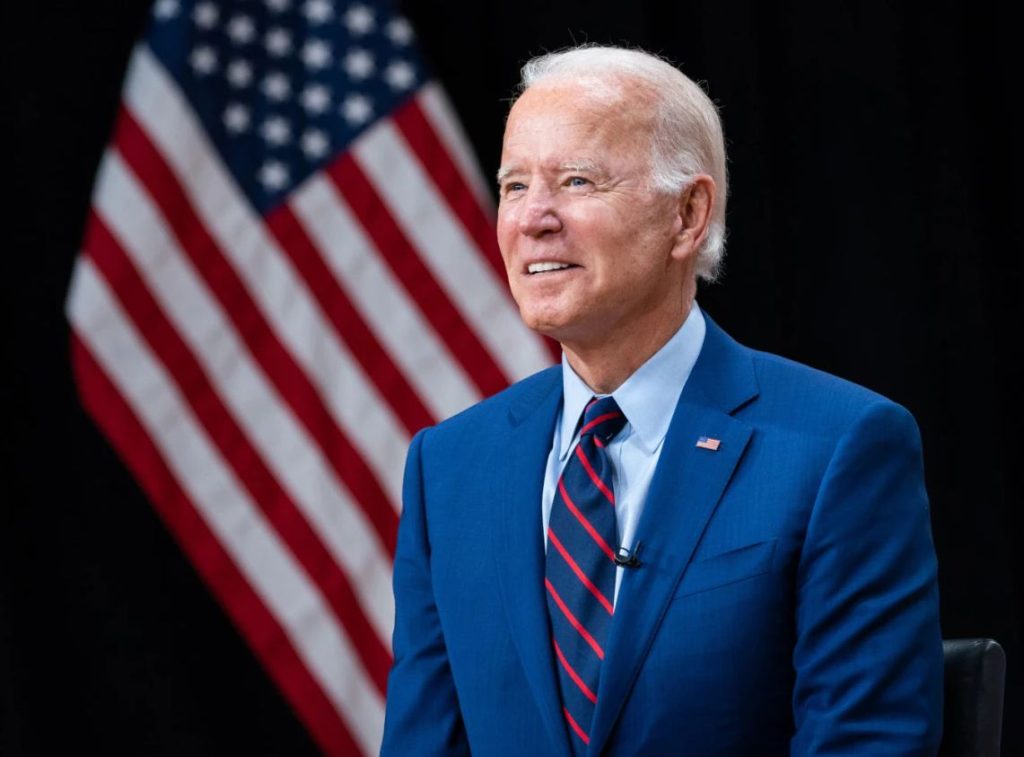

Biden’s AM Forward program expands

Another trend that gained momentum was the growing enthusiasm of multinational contractors to join US President Joe Biden’s AM Forward initiative. Initially launched in May 2022, the project is designed to promote 3D printing’s uptake by SMEs as a means of helping secure their supply chains and revitalizing US manufacturing.

During August, Boeing and Northrop Grumman joined AM Forward as well. In doing so, the firms committed to buying more 3D printed parts from US suppliers, as well as providing them with technical support to aid their qualification efforts.

“We know the competitiveness of the US industrial base, including Boeing, relies on the capability of a wide spectrum of suppliers producing and post-processing critical aerospace parts,” said Dr. Melissa Orme, Vice President of Boeing Additive Manufacturing. “Through AM Forward, we are confident we can collaboratively accelerate AM adoption at scale; increase the agility, capacity, and resiliency of US supply chains; and support and expand good-paying jobs across the US.”

High-end automotive adoption continues

Following the UK track debut of its 3D printed Czinger 21C hypercar at the Goodwood Festival of Speed, Divergent Technologies unveiled two more use cases of its Divergent Adaptive Production System in August. Not only was an Aston Martin with a Divergent-3D printed rear assembly rolled out, but the follow-up to the 21C was introduced, the partially 3D printed four-door Czinger Hyper GT saloon.

A month later, it was revealed that McLaren 3D prints up to 9,000 F1 parts each year using Stratasys’ technologies. Specifically, leveraging its five Stratasys Neo 800 3D printers, the outfit is said to have created aerodynamic parts across its front and rear wing R&D programs, as well as large elements of its 2022 car’s side bodywork and top body.

“Wind tunnel testing is still the gold standard when assessing how every surface works together, either as an assembly or as a complete car,” the team’s Head of AM Tim Chapman, explained at the time. “Our Neo series of 3D printers have helped us to dramatically reduce the lead times of our aerodynamic wind tunnel components and projects.”

Paving the way for clean energy

3D printing continues to be deployed in pursuit of new clean energy solutions, and August saw it applied in several novel projects in this area. In the early days of September, Cornell University, alongside its start-up Dimensional Energy and Lithoz, was awarded a grant to develop novel ceramics that could be used for the 3D printing of clean energy reactor parts.

Since raising $50,000 in funding, researchers at the firms have attempted to develop a new type of ceramic that’s better able to withstand the high temperatures of thermocatalytic reactors in operation. At the time, the team said it could be possible to use 3D modeling and 3D printing to layer their material into structures shaped specifically to improve both resilience and reactor CO2 conversion rates.

A team at the Hebrew University of Jerusalem also developed a novel wood-based 3D printing material that proved capable of morphing into pre-designed shapes. According to its developers, the eco-friendly feedstock could shapeshift due to the fiber orientations in its wood content, which caused it to warp as it dried. With R&D, it was said the material could be used to create self-assembling furniture.

Medical devices make it to human trials

In August, researchers also made significant progress in the development of implantable 3D printing devices. Scientists at the L V Prasad Eye Institute, Indian Institute of Technology (IIT) Hyderabad and the Centre for Cellular and Molecular Biology managed to test India’s first 3D printed cornea on animals for the first time, leading them to claim that it could soon “be used in human beings.”

That month, BellaSeno’s 3D printed breast implants also entered human trials. The firm’s breast scaffolds are fully-resorbable in that they’re designed to be implanted during breast regeneration, augmentation, or revision surgeries before being slowly absorbed by the body. Following the success of initial trials earlier in 2022, BellaSeno unveiled plans to use its implants to treat further breast deformity patients.

“This trial is a very important step for us to demonstrate that our approach is not only safe but leads to substantial improvements in terms of long-term safety, health, and quality of life,” said Dr. Tobias Grossner, CMO of BellaSeno. “We very much hope the trials once more confirm our scaffold-guided tissue reconstruction concept.”

2022: 3D Printing Industry review of trends and news

2021: 3D Printing Industry review of trends and news

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a NUBURU blue laser. Photo via NUBURU.