Interested in reading more about the year’s biggest 3D printing news? You can access our full 3D Printing Industry Review of the Year series here.

Russia’s invasion of Ukraine shook the western world in February 2022, and the 3D printing industry was not immune from the aftershocks of the following events. Not only have manufacturers been impacted by worsening supply chain issues, but some have been forced to relocate to avoid the fighting, and the technology has aided the medical and war-fighting efforts of either side.

In more positive news, the month did see advances in 3D printing sustainability, additively manufactured electronics, and 3D bioprinting. SLM Solutions’ strong FY 2021 performance also saw its reputation continue to grow, and strong demand for its technologies ultimately tempted an electronics powerhouse into buying it.

Read on for more from the Massachusetts Institute of Technology, GREENFILL3D, CollPlant, CELLINK, NextFlex, In-Q-Tel, Scrona, Nuclera, Volumetric Biotechnologies, Harvard Medical School, Sichuan University, and more.

3D printing in Russia’s Ukraine war

As with many other industries, talk in 3D printing during February was very much focused on the impact of Russia’s full-scale invasion of Ukraine. While some industry firms fled the fighting, others were left contemplating what the war would mean for the global markets still reverberating from the shock of COVID-19. In one use case, Russia was even found to be developing 3D printing-enhanced MiG-31 fighters, which have been retrofitted to extend the performance of their jet engines.

As the war has waged on, the 3D printing community has also united to find ways of deploying the technology to aid Ukraine’s defensive efforts. Much of the 3D printing sector embargoed Russia over its war in March 2022, and the likes of 3YOURMIND, Sygnis and TeenCrunch launched the Tech Against Tanks initiative, which saw medical, tactical, and protective gear 3D printed for Ukraine.

Sustainability drive gains momentum

Improving the sustainability of 3D printing may have been in many firms’ crosshairs for some time now, but there was evidence to suggest this push progressed in February. At the Massachusetts Institute of Technology (MIT), for instance, researchers revealed they’d come up with a plant-based 3D printing material that’s both “tougher than some types of bone and harder than typical aluminum.”

Taking a different approach to reaching its sustainability goals, CD3D spin-out GREENFILL3D launched a spaghetti filament for 3D printing displays. Made from wheat bran, the waste left over from pasta production, PLA and other biodegradables, the ‘Branfill3D’ material was said to be flexible but resilient.

Earlier that month, scientists at Johannes Kepler University Linz also investigated the eco-friendly 3D printing of soft robotics. Capable of stretching to six times their original length, the team’s test parts were designed to address the sustainability concerns around developing soft robots made from non-biodegradable materials.

Backing electronics 3D printing R&D

Another emerging field that continues to be the focus of extensive R&D is electronics 3D printing. In February, NextFlex’s $11.5 million project call saw funding offered to projects across several categories, with each designed to advance US flexible hybrid electronics (FHE) and the interests of the US Department of Defense.

In one of several other US government-backed electronics initiatives, CIA investment arm In-Q-Tel provided backing to Electroninks. Using the capital, it was said the firm would be able to scale the production of its particle-free silver aerosol jet printing (AJP) inks so that it’d be better able to meet demand from both commercial and industrial clientele.

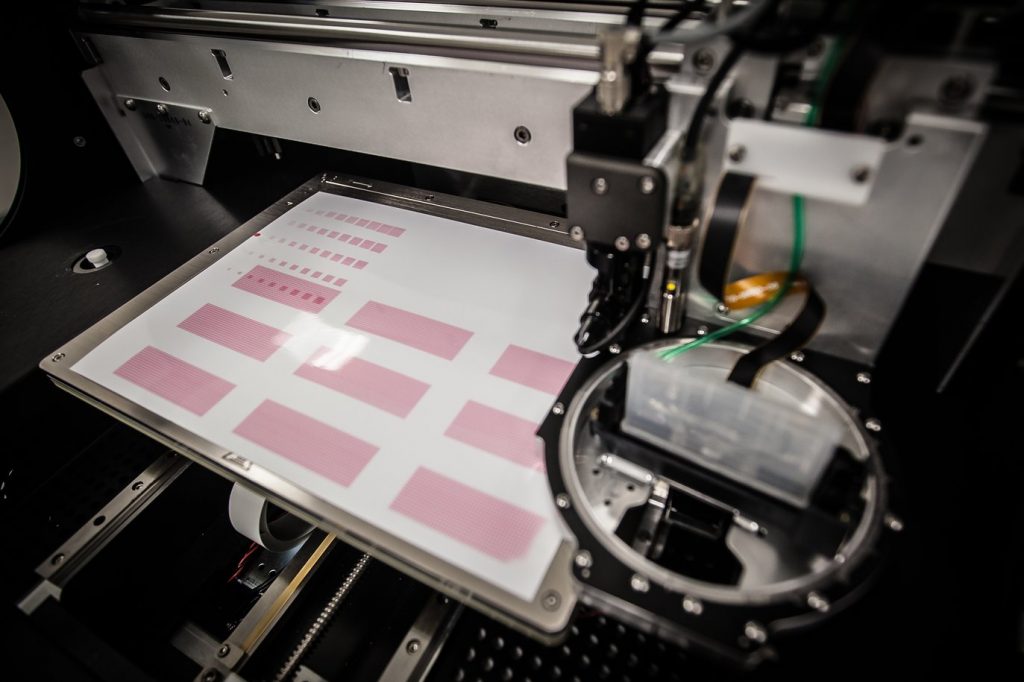

From private investors, ETH Zurich spin-out Scrona AG also raised $9.6 million towards the development of a novel high-resolution approach to 3D printing electronics. Unlike ordinary inkjetting, the firm’s Electrostatic Multi-Nozzle Printing process utilizes a piezoelectric field generated just outside the tip of a nozzle, to jet multiple materials onto substrates at a sub-micron level of accuracy. The firm’s backers included stalwarts like AM Ventures, TRUMPF Venture, and Verve Ventures.

Bioprinting advances on several fronts

Though implantable 3D bioprinted organs and tissues remain some way from end-usage at scale, the technology behind them did make small steps forward in February 2022. That month, scientists at Utrecht University announced the development of volumetric 3D bioprinted livers, capable of performing key toxin elimination processes akin to those that natural livers perform in our bodies.

At Harvard Medical School and Sichuan University, researchers also developed a means of 3D bioprinting live human muscle tendons. Known as ‘cryo-bioprinting,’ the team’s process sees cells frozen and stacked vertically, in a way that allows for the creation of more robust and versatile freestanding, mixed-cell tissues with regenerative medicine, drug discovery and custom therapeutic potential.

In February, CollPlant partnered with BICO firm CELLINK as well, in an effort to ramp up its production of 3D bioprinted breast implants. Said to be undergoing preclinical trials at the time, the grafts are designed to degrade over time and be replaced by native tissues, in a treatment that’s designed to be safer than traditional augmentation procedures.

Another big player joins the AM party

During the month, SLM Solutions beat its FY 2021 guidance in a result that reflected the strong performance of its offering in the aerospace and automotive industries. As the year went on, it was revealed that the company’s offering had been adopted by Divergent Technologies, maker of the Czinger 21C 3D printer hypercar, and it was later contracted to build the ‘world’s largest metal 3D printer.’

Undoubtedly, this demand attracted the attention of investors, and Nikon bid $622 million for SLM Solutions later in the year. Though Nikon has previously held minor stakes in 3D printing firms, the size of the investment suggests that it now intends to play a bigger role in the industry once the deal is wrapped up in the new year.

2022: 3D Printing Industry review of trends and news

2021: 3D Printing Industry review of trends and news

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Russian Air Force Mikoyan-Gurevich MiG-31 fighter jet. Photo via Wikipedia Commons.