ETH Zurich spin-out Scrona AG has raised $9.6 million towards the development of a novel high-resolution approach to 3D printing electronic devices.

Unlike conventional inkjetting, the firm’s Electrostatic Multi-Nozzle Printing process utilizes a piezoelectric field generated just outside the tip of a printing nozzle, to jet multiple materials onto substrates at a sub-micron level of accuracy, potentially allowing for the creation of PCBs, semiconductors and displays at a 100-times higher resolution than before.

Having gained Series A backing from AM Ventures, TRUMPF Venture, Verve Ventures and Manz Management Consulting and Investment, Scrona now aims to “accelerate the industrialization” of its technology, as it seeks to bring it to market.

“Scrona is enabling customers to digitally print the impossible – on any material, at scale, improving the speed, accuracy and cost of manufacturing,” said Dr. Patrick Galliker, CEO of Scrona. “We are very excited to be supported by this syndicate of expert investors who understand the disruptive potential of Scrona‘s scalable printing technology, which has the ability to reduce manufacturing steps ten-fold, while also significantly reducing material, energy and water usage.”

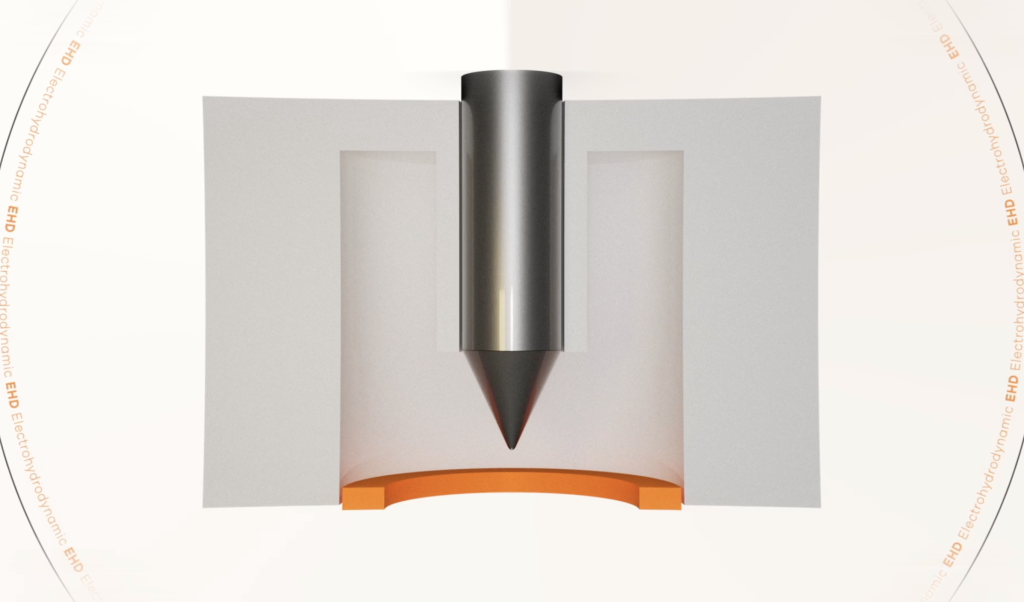

Electrostatic Multi-Nozzle Printing

While the 3D printing of electronics has come on leaps and bounds in recent years, Scrona says that existing technologies still “face limitations” when it comes to meeting growing demand for multi-material devices with tiny feature sizes. In large part, the firm blames the drawbacks of current inkjet approaches, on their reliance on nozzle-based jetting, which only enables the deposition of narrow droplets.

To overcome this perceived drawback, Scrona has therefore come up with Electrostatic Multi-Nozzle Printing, a process in which a piezoelectric field is instead used to ‘pull’ inks from a nozzle. In doing so, the technology effectively focuses all jetting energy at the nozzle’s very tip, enabling the ten times faster deposition of smaller droplets, at resolutions as high as 0.5 μm, layer-by-layer into objects.

With further R&D, the company believes it could be possible to condense thousands of these nozzles into MEMS systems, capable of depositing metals, dielectrics, biomaterials and organic inks that existing processes just can’t handle. The programmable nature of the microfabrication technology behind these nozzles, also allows for their full customization, lending them several potential applications.

“There is enormous potential for Scrona technology in additive manufacturing because its technology can process materials that are simply not processable with other printheads today, “ said Johann Oberhofer, Managing Partner at AM Ventures. “The combination of the highest resolution and the ability to overcome restrictions around high-performance materials of current processes is unique.”

“I expect that Scrona’s technology will enable completely new applications and we are glad to accompany them on their journey together with a strong investor line-up.”

Scrona’s $9.6m funding boost

The majority of Scrona’s newly-raised funding has come from a $6.7 million Series A funding round led by AM Ventures, a company with a track record of helping emerging businesses bring their technologies to market. In the past, the firm has backed the now-industry stalwart DyeMansion, and having set up a €100 million venture capital fund last year, it continues to support start-ups across the sector.

Likewise, fellow backer TRUMPF Venture has an eye for emerging technologies itself, as it recently acquired TRUMPF SISMA, a joint venture it established alongside SISMA in 2014 to hone the Laser Metal Fusion process, while the Swiss Secretariat for Education, Research and Innovation (or SERI) has also lent its support to Scrona, pledging to provide the remaining $2.9 million in the form of a grant.

Using the capital raised across these investment channels, Scrona anticipates being able to bring its technology to market much more quickly, and test its efficacy within new applications such as the creation of micro-LED displays and AR glasses. Although the firm hasn’t set a timescale for its commercialization, it’s reported to be seeking collaborations with Tier 1 equipment manufacturers by 2024.

“A broad spectrum of materials can be printed at industrial scale with Scrona’s advantageous technology,” adds Michael Blank, Head of Verve Ventures’ investment team. “This is a quantum leap for a wide range of industries from semiconductors to molecular printing in biotechnology.”

Interest in 3D printed electronics surges

With 3D printing beginning to emerge as a viable alternative to traditional electronics production processes, those developing such technologies are also starting to attract the attention of investors. Earlier this month, Q5D Technology secured $2.5 million in funding to support the development of its 5-axis CU500 wiring and electronics 3D printer.

Similarly, on the military front, BotFactory has gained US Air Force funding to develop a fully-automated desktop electronics 3D printer. Designed to be capable of 3D printing and assembling printed circuit boards (PCBs) on-site and on-demand, it’s thought that once ready, the system could save the US military millions in procurement costs.

As one of the early leaders in the electronic 3D printing sector, Nano Dimension has also poured a huge amount of funding into the R&D of related technologies. In one such initiative, the company co-founded the $6 million J.A.M.E.S venture with sensor specialist HENSOLDT in June 2021, which has seen the creation of a designer community, working to advance additively manufactured electronics (AMEs).

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

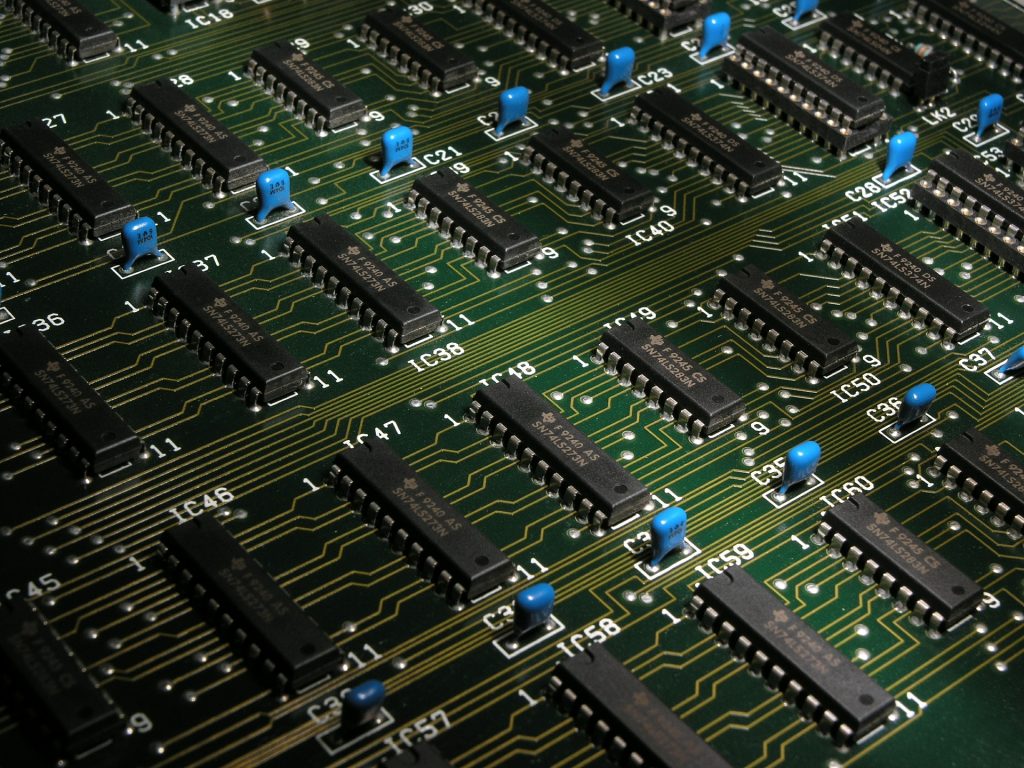

Featured image shows a set of integrated circuit boards. Photo via Magnascan, Pixabay.