NextFlex, a consortium dedicated to advancing US flexible hybrid electronics (FHE) production, has issued a call for projects that advance its cause.

Through its latest $11.5 million project call, the organization is seeking out innovative approaches to the creation of FHEs that both address advanced manufacturing issues, and the priorities of the US Department of Defense.

“We are delighted to announce this new round of funding for advanced manufacturing developments in the US,” said Malcolm Thompson, PhD, Executive Director of NextFlex. “The benefits of FHE – additively manufactured electronic systems that are lightweight, thin, and conformable, are transforming our perceptions of how ubiquitous electronics can truly be.”

“With each successive project call, the NextFlex member community moves the technology closer to commercialization and wide adoption.”

NextFlex’s DoD-backed initiatives

Launched in 2015 under an Air Force Research Laboratory (AFRL) Cooperative Agreement, NextFlex is essentially a group of electronics firms, academic institutions, nonprofits and government partners, with the shared goal of facilitating FHE innovation, both as a way of making their production more sustainable and informing workplace practices.

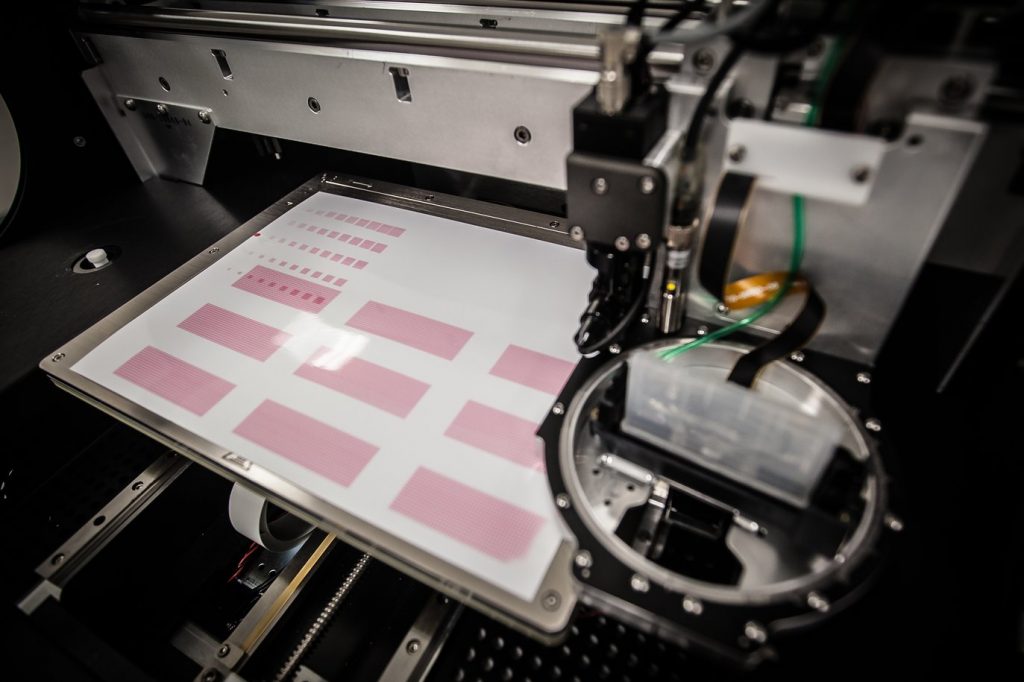

One way NextFlex has sought to encourage such advances is via its own pilot-scale manufacturing line. Known as the Technology Hub, this facility is fitted with two ITAR and FDA Quality Systems Regulation-compliant cleanrooms as well as inkjet, aerosol jet and extrusion systems, and lab space for device production, integration and testing.

Under its initial arrangement with the AFRL, the consortium also gained $75 million in funding, which it has since redistributed to those developing lightweight, stretchable FHEs. Over the last seven years or so, NextFlex has made a particular habit of backing those focused on the conformal 3D printing of electronics onto existing surfaces, awarding $3 million to Optomec in 2017 with this in mind.

Other beneficiaries of the organization’s support include Lockheed Martin, which gained a share of a $12 million NextFlex investment a year later, in return for compiling a database of 3D printed antenna and microwave elements, with another 12 projects being awarded $11.5 million during May 2020, taking its total spending to over $100 million.

Since then, the group has gone on to enter into a cost-sharing agreement with the AFRL, that has seen the DoD commit to providing it with up to $154 million, in order to give it the spending power necessary to support the development of advanced electronics, which can truly address US defense needs.

“We are excited to continue our partnership with NextFlex and its members,” AFRL Chief Scientist Dr. Richard Vaia said at the time. “The Flexible Hybrid Electronic manufacturing ecosystem did not exist five years ago. Today these technologies are not only providing component solutions to our current platforms, but are revolutionizing our design concepts for future transformation capabilities for 2030.”

$11.5M on offer to FHE innovators

As part of its latest call-to-action, its seventh in seven years, NextFlex is making an initial $11.5 million in funding available, although it expects actual project investment to be higher, once cost-sharing is taken into account. As far as entries go, the consortium says it’s seeking projects that propose FHEs which address “high-priority US manufacturing opportunities” and “areas of emerging importance.”

Specifically, NextFlex is encouraging applications with automotive or packaging potential, as well as those involving the R&D of novel approaches to FHE fabrication, dielectric materials or production methods, the addition of integrated circuits to electronics, making such devices more eco-friendly, the creation of soft, stretchables and wearable manufacturing.

Alongside its project call, the organization has also made its FHE Technology Roadmap public for the very first time. Designed to inform NextFlex’s funding priorities, the documents are packed with information on the current market opportunities, needs and stakeholders in the world of printed electronics, in addition to a five-year roadmap, focused on filling the ‘technical gaps’ it has identified.

Through this roadmap and its latest project guidebook, the group suggests that entries should be “industrially-led” where appropriate, have a “significant US presence” and a “clear path towards commercialization.” In terms of the actual content of submissions, NextFlex says that they need to include enough detail to make methods replicable at its Technology Hub, while funding must be split 1:1.

More details about project call 7.0 are set to be revealed at the Proposer’s Day and Teaming Event on March 1, 2022, at NextFlex’s Winter FHE Symposium, where attendees can pose questions and form proposal teams if desired. The consortium’s deadline for applications is April 14, 2022.

Those interested in attending the event can find out more here.

Investing in innovative electronics

Despite still being at a relatively early stage of commercialization, the field of electronics 3D printing continues to attract a significant amount of investor interest. Earlier this month, ETH Zurich spin-out Scrona AG raised $9.6 million towards the development of a high-resolution electronics 3D printing approach, from high-profile backers such as AM Ventures.

Nano Dimension, one of the early leaders in this area, has also poured a huge amount of funding into R&D. In one such initiative, the firm co-founded the $6 million J.A.M.E.S venture with sensor specialist HENSOLDT in June 2021, which has seen the formation of a designer community, working to advance additively manufactured electronics (AMEs).

On a more commercial level, nScrypt continues to invest in the development of its Factory in a Tool (FiT) systems, and late last year, it launched a toolhead that enables the 3D printing of multi-axis electronics onto curved or irregular surfaces. To demonstrate the microdispensing capabilities of this ‘SmartPump’ device when it first came out, the firm 3D printed its own n-shaped logo onto a computer mouse.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printing process used by one of NextFlex’s members to produce FHE components. Photo via NextFlex.