In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across our industry.

Today’s edition features new software and product launches, testing of 3D printed engines at a space center and of course 3D printers named after ancient gods.

Read on for the latest news from Sintavia, Sandvik, Xaar, Amaero, 3Diligent, Shining 3D, DP Technology, and more.

Santavia gains Nadcap approval, Sandvik’s superalloys certified

We begin with the latest accreditations, and Sintavia, the metal 3D printing service, has gained National Aerospace and Defense Contractors Accreditation Program (Nadcap) approval for heat treatment at its Hollywood and Davie locations in Florida. Nadcap is an industry-managed certification, which is designed to ensure high standards and quality controls are followed within the aerospace sector. Sintavia announced it is now the sole Nadcap approved enterprise for laser additive manufacturing, electron beam additive manufacturing, and in-house heat treatment. The accreditation is valid until July 31st, 2021.

The company also holds Nadcap approvals for non-destructive testing and chemical processing through its subsidiary, QC Laboratories. Sintavia plans to pursue approval for its in-house metallurgical and mechanical testing laboratory in its Davie facility at a later date.

“[Nadcap approval] will allow Sintavia to provide higher quality production parts more quickly to its customers. Moreover, we are proud of the fact that we are the first manufacturer anywhere in the world to achieve these quality accreditations,” said Brian Neff, Sintavia’s Chief Executive Officer.

Sandvik’s new powder plant for titanium and nickel-based superalloys has recently received ‘AS9100 Revision D’ certification for deliveries to the aerospace industry. Opened in the Sandviken area of Sweden in 2019, the plant has gained the certification for qualifying its Osprey titanium powder with the best possible consistency, morphology, and quality, for use in additive manufacturing. The certification is an internationally recognized Quality Management System (QMS) for the aerospace industry, ensuring that its recipients continually improve, focus on meeting customer requirements, and ensure customer satisfaction.

“Now we are one of few companies that has the new and prestigious ‘AS 9100D’ quality certification for our Osprey titanium powder and nickel-based superalloys used for additive manufacturing. It is a true milestone, which will facilitate many customer collaborations going forward,” said Keith Murray, VP of Global Sales at Sandvik Additive Manufacturing.

Business news: Tevo rebranded, Investment at Xaar, NextFlex funding reaches $100m

In 3D printing business news, Chinese 3D printer manufacturer Tevo has rebranded itself Homers 3D printers. After a quiet start to the year from the manufacturer of budget FDM printers, the company is back with a relaunched website. Sporting a new theme with an apparent homage to Homer’s Greek mythology, the revamped website will not only sell older Tevo stock but also improved versions of older models with mythological names such as the Homers (sic) Poseiden and the Homers (sic) Odysseus.

Three members of senior management at Xaar, the developer of digital inkjet technology have invested in the company, buying a combined 275,000 shares between them. John Mills, CEO, Ian Tichias, CFO, and Andrew Herbert, company chairman, all invested in the company after the announcement of Xaar’s full-year results yesterday for the 12 months ending 31 December 2019.

“2019 was a difficult year for the group as a result of the performance of the printhead business and the decision to end investment in thin film. However, we entered 2020 with confidence in the long-term future of the business and a revised strategy, product roadmap and strong balance sheet to deliver improved business performance and a return to profitability,” said John Mills, Chief Executive Officer of Xaar.

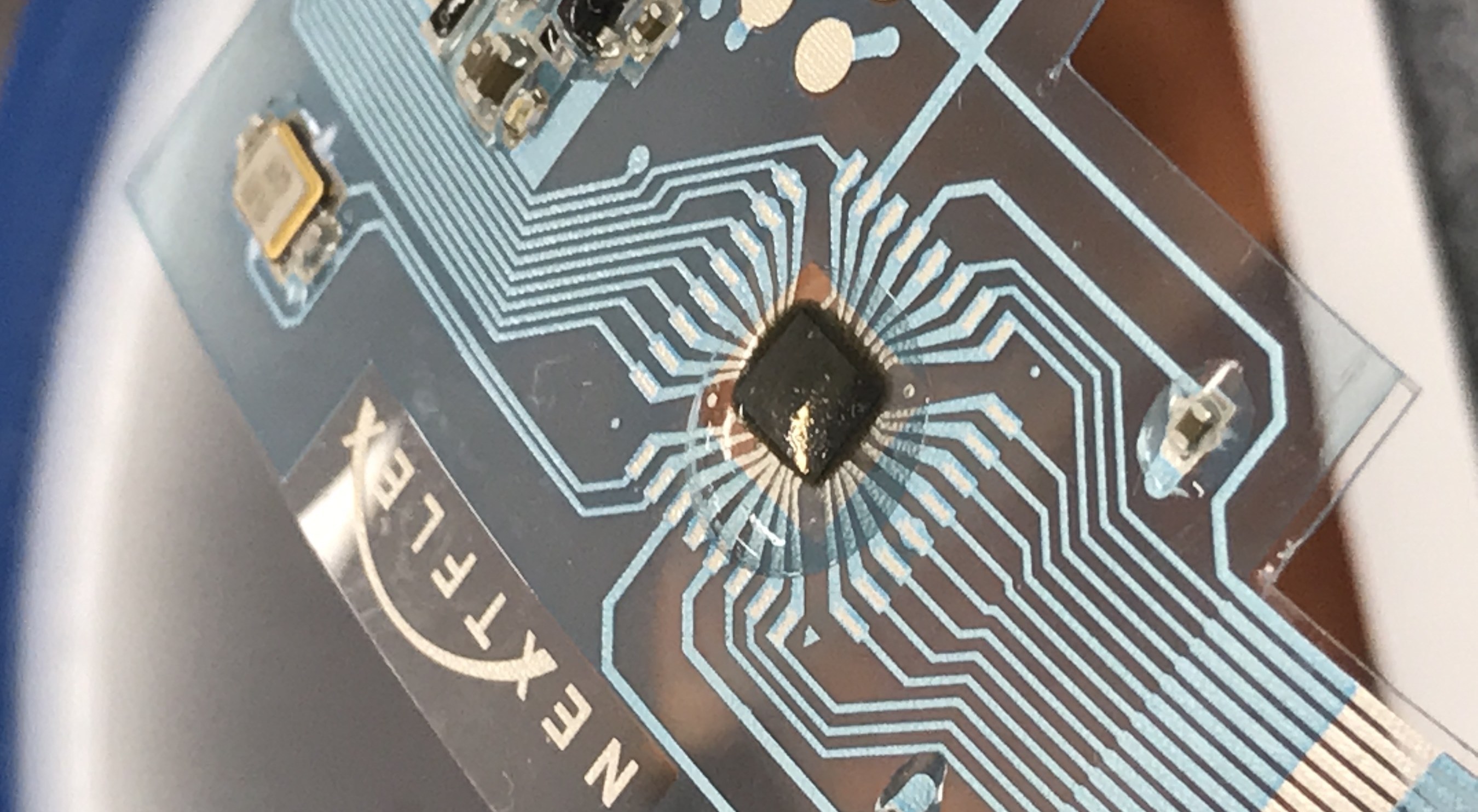

NextFlex, a U.S consortium of companies seeking to advance the manufacture of Flexible Hybrid Electronics (FHE) in the U.S, has announced $11.5 million in funding for new projects. The latest round of funding brings the total amount invested by NextFlex in FHE developments to over $100M. The money will go to 12 projects, with applications focusing on aerospace, structural health monitoring and sophisticated array antennas to help move FHE technology closer to volume manufacturing and commercialization.

“With several projects focused on the manufacturability and reliability of FHE systems and devices, this current round of funded projects demonstrates an overall maturation of FHE technology. This showcases the considerable progress and investment occurring within the advanced manufacturing sector, despite aspects of the economy that might be temporarily stalled,” said Malcolm Thompson, Executive Director at NextFlex.

New materials for Makerbot and Rapidshape customers

MakerBot, the Brooklyn-based manufacturer of the METHOD 3D printer, has expanded its materials portfolio with the additions of PC-ABS and PC-ABS FR. PC-ABS (polycarbonate-acrylonitrile butadiene styrene) has high heat resistant properties and tensile strength, while PC-ABS FR is a flame-retardant material that meets the UL-94 V0 standard, an important fire safety specification. The materials are ideal for applications such as automotive and rail parts, LCD panels, appliances, adapters, chargers and portable handheld devices. In addition, because PC-ABS is often used to create end-use injection molded parts, Makerbot engineers will now be able to better produce functional prototypes in order to carry out representative checks.

“PC-ABS is another example of METHOD’s ability to support […] materials that print more successfully with a heated chamber. This improves the success rate and efficiency of the prototyping process, reducing time to market for new products,” said Johan-Till Broer, VP of Product Development at MakerBot.

German 3D printing manufacturer Rapid Shape has announced a partnership with dental materials specialist VOCO. Rapid Shape has brought a series of 3D printing systems to market designed specifically for dental professionals, and the deal will see VOCO’s portfolio of dental 3D printing materials become available to users of Rapid Shape machines.

Amaero launches SP500 and SP100 3D printers in the US, Shining 3D launches the ‘Inspec’

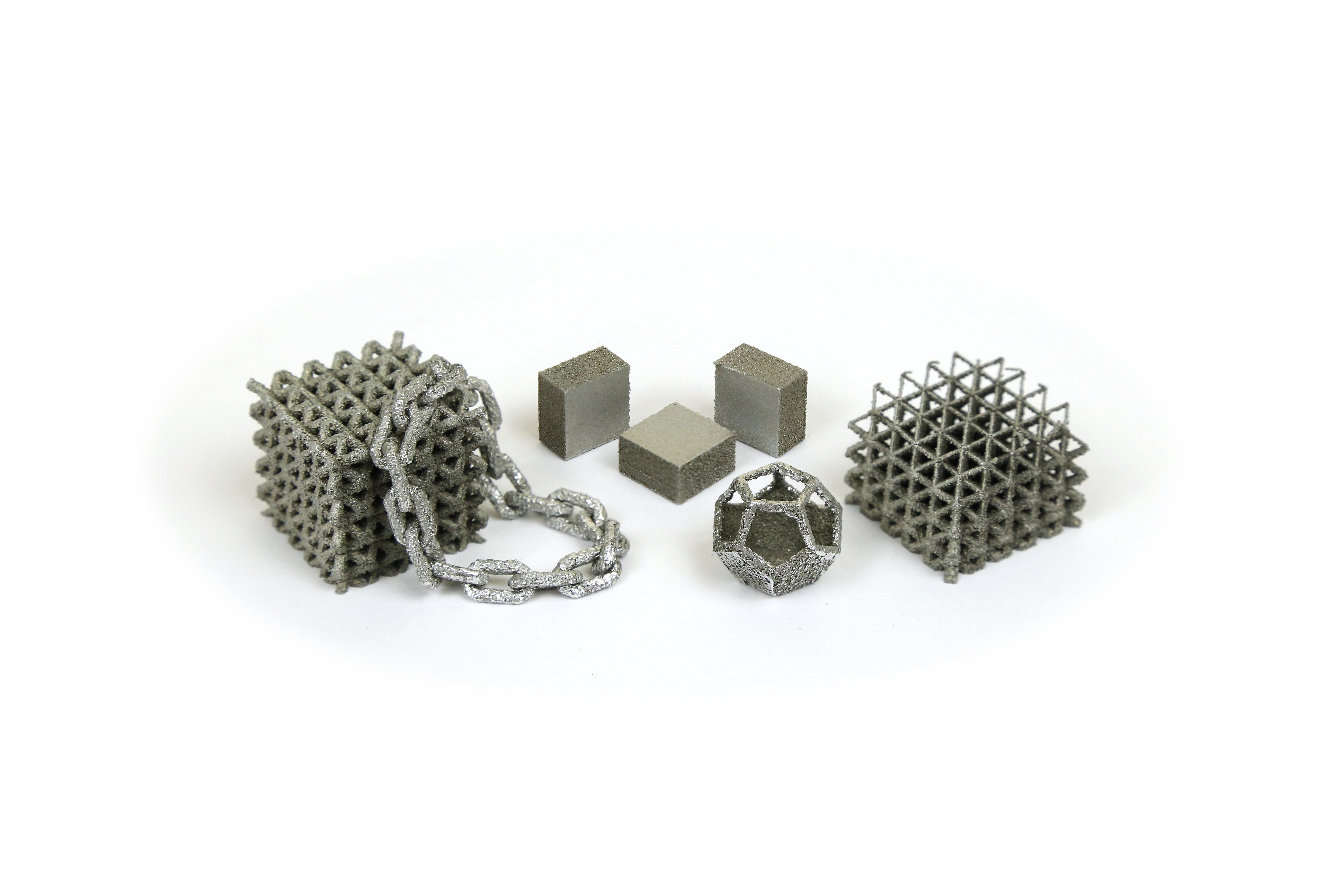

Australian metal additive manufacturing service provider Amaero has celebrated the release of its first AmPro SP500 and SP100 machines in the United States at its new facility in El Segundo, California. The AmPro SP500 3D printer is particularly suited to the manufacture of steel tooling. With a large build area of 500 x 250 x 250 mm and features such as removable build cartridges, it has minimal factory floor impact compared to traditional machine tool options.

The SP100, on the other hand, is a simple to use, easy to maintain alternative, which is ideal for low volume production. It has a smaller laser powder bed fusion platform, with a build envelope of 100mm diameter and 80mm in build height, which are ideal for research and development purposes.

“This is a significant milestone in our company’s overall growth strategy as we are now able to really accelerate our sales strategy. Having the AmPro SP500 and SP100 operational for the first time, marked the start of our machine sales in the United States, [and] machine sales form an important part of our business plan and strategy,” said CEO, Barrie Finnin.

Hangzhou-headquartered 3D printer manufacturer Shining 3D, has launched its new automatic desktop 3D inspection system, the Autoscan-Inspec (or Inspec for short).The system integrates 3D scanning with 3D inspection, and is designed to improve the efficiency of scanning small and complex parts. Featuring the company’s blue-light 3D scanning technology, the system enables users to scan within 10μm to ensure a high level of accuracy, and its 5MP dual-camera provides precisely detailed 3D scans of small and complex objects. According to Shining 3D, applications include inspection and quality control, reverse engineering and product design.

DP Technology releases software update, 3Diligent relaunches ProdEX

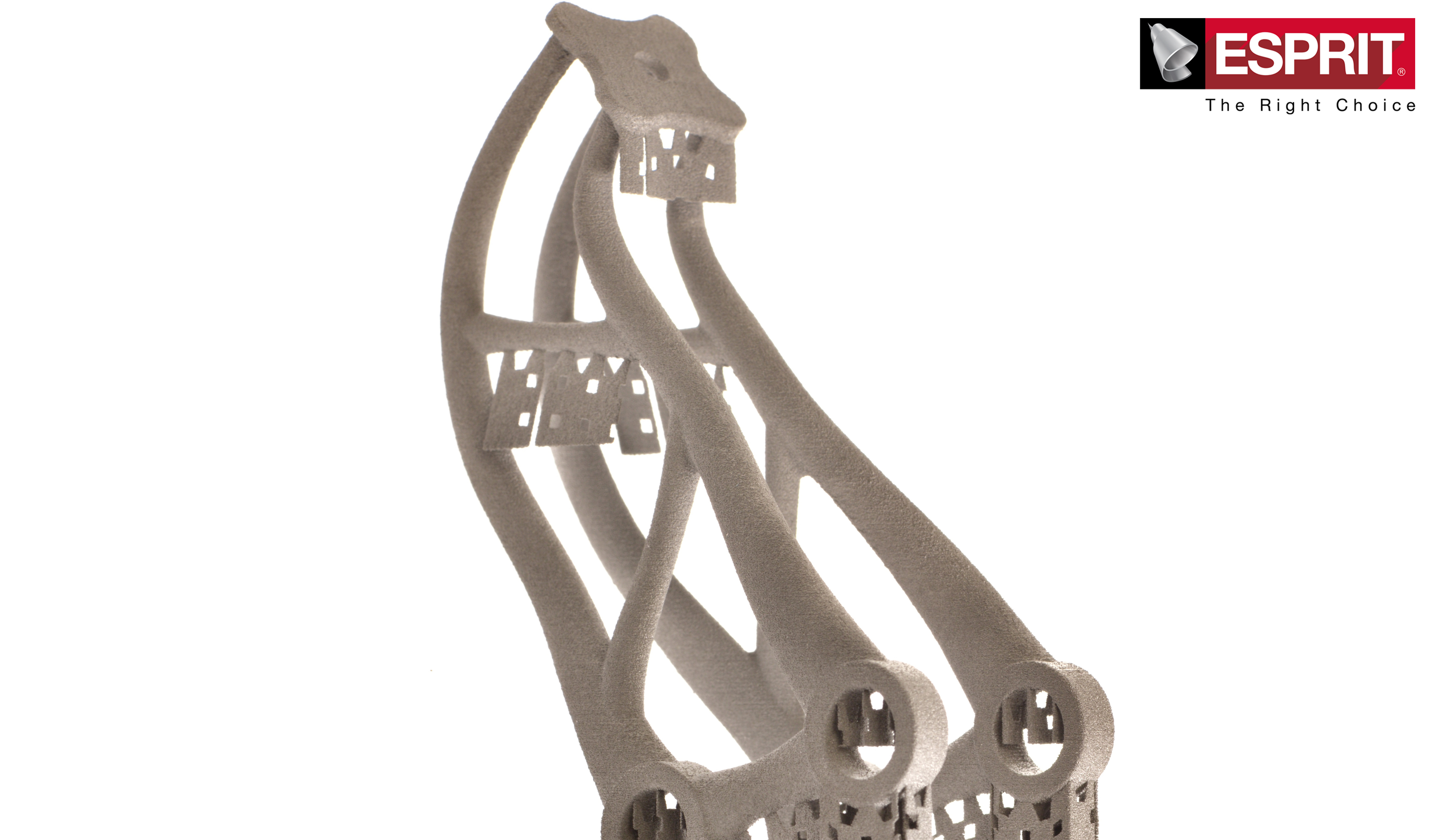

In the latest software developments, DP Technology, the developers of Computer-Aided Manufacturing (CAM) software, has announced a new update to its ESPRIT CAM system. The update includes new features such as a balanced turning cycle, in addition to enhancements to existing features such as probing and additive Directed-Energy Deposition (DED). The balanced turning cycle enables users to use two tools to make simultaneous cuts to the same workpiece and reduces cycle times by taking heavier cuts with pinch turning. The new ESPRIT also brings expanded probing features, which uses a 4th-axis measurement, 5-point rectangle, angled surface and angled web/pocket, to improve the intelligent cycle selection by supporting more advanced scenarios.

“Although each new feature offers a discrete set of benefits to users, combining them into one large release helps keep our software on the cutting edge and minimize disruptions in our customers’ shops. In this version, users can enjoy features including coolant improvement, drilling interrupted holes, collinear axes, and other ways to expand their capabilities,” said Tania Campanelli, Director of Research and Development for DP Technology.

3Diligent, a Californian digital manufacturing service provider, has launched its updated procurement service ProdEX, along with 3Diligent Shopsight, a new manufacturing shop management software. Working as part of 3Diligent’s Industry 4.0 offering, ProdEX allows procurement buyers and engineers developing products to source custom parts on-demand through a secure web portal. The service includes dynamic assessment, quoting, and fulfillment of requests using proprietary algorithms, in addition to search tools that allow customers to search for and identify solutions from the ProdEX database.

Shopsight meanwhile, allows manufacturing shop operators to streamline and enhance their pre-production and production operations. With its pre-production solution, suppliers can leverage 3Diligent tools to assess which technology-material combinations are viable for a job. 3Diligent’s production package also enables fabricators to ensure consistent quality and efficiency once an order has been received with integrated task lists, job routing, and audit trails.

Nano AL scoop 3D printing award for its Addalloy powder

NanoAL, LLC has been revealed as the winner of a Gold Edison Award for 3D Printing Enhancements for their proprietary Addalloy aluminum powder. The award, which has been running since 1987, recognizes the best in 3D printing innovation, and Nano AL’s aluminum powder was chosen as the 2020 Gold Award winner by a panel of over 3,000 leading business executives.

The aluminum alloy powders are specifically designed and developed for selective laser melting (SLS). The proprietary compositions take advantage of the atomization and SLM printing processes, to create advanced microstructures with non-traditional strengthening mechanisms that enhance the performance of 3D printed components.

“After a thorough review, the Edison Awards Judges recognize NanoAL Addalloy Powder as a game changing innovation, standing out among the best new products and services launched in their category,” said Frank Bonafilia, Executive Director of the Edison Awards.

Launcher to test 3D printed engines at Stennis Space Center

Finally, American private aerospace company Launcher has signed an agreement with the Stennis Space Center to test 3D printed engines at its Mississippi facility. The deal allows Launcher to use the E-1 test stand at the center to test its engine, which it is developing for a small launch vehicle. The agreement is a long-term one, and Launcher plans to perform full-scale E-2 engine tests at the site, with the stated goal of fully testing the engine there by the end of 2021.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on the Metal 3D printing process by Shining 3D. Photo by Michael Petch.