In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across our industry.

Today’s edition features an update on Formnext, a change in leadership at 3D Systems, America Makes’ new AXIOM project, Electron Beam (EB) welding guns, and a ‘Dream Bus’ full of desktop 3D printers.

Read on for the latest news from 3D Systems, Kingsbury, Amaero, Farsoon, Digifabster, Complete 3D, Sciaky, Karmen and Elementum 3D.

The latest partnerships in additive manufacturing

Beginning with the most recent collaborations in 3D printing, engineering firm Visagio and digital supply chain service provider DiManEx have agreed to combine their services into one offering. Integrating Visagio’s supply chain services with DiManEx’s end-to-end platform, will help businesses to optimize their supply chain through digitized inventory, producing parts on demand via 3D printing and delivering them worldwide. The partnership represents a change of approach for both companies due to the Covid-19 pandemic, and they’re now seeking to pool their skills in supply chain, inventory and Maintenance Repair and Overhaul (MRO) spare parts management.

“Companies are increasingly looking for ways to optimize their supply chains and mitigate risks, such as those brought about by pandemics or geo-political tensions,” said Tibor van Melsem Kocsis, founder and CEO of DiManEx. “Our platform embeds 3D printing in supply chains easily. Coupled with Visagio’s industry and management expertise, this is a winning combination for supply chain optimization,” he added.

Amaero, the metal additive manufacturing service provider, has signed a research agreement with the Australian insulation company Fletcher Insulation. The deal will see Amaero test and develop a new tooling production technique at Fletcher’s manufacturing facilities, with the companies planning to commercialize the new methods after testing is complete. The agreement will see Amaero continue to expand the applications of its technology at Fletcher Insulation’s two manufacturing plants, and fourteen branches across Australia.

“We are very pleased to have entered this Agreement with Fletcher Insulation. In the coming months we will print tooling that will be tested at full operational load. If successful, Amaero expects to win supply agreements for tooling to be manufactured in our Melbourne and Los Angeles facilities,” said Amaero CEO, Barrie Finnin.

Formnext 2020 announces plans will go ahead

Organizers have confirmed that the Formnext 2020 exhibition will go ahead as planned, with updated health and safety precautions in place, and additional virtual offerings to cater for those that cannot attend. Mesago Messe Frankfurt GmbH is working on measures to safeguard the health of all attendees, after the German federal government ruled that trade shows don’t pose a particular health risk to the public. Measures being considered include reducing visitor density, guaranteeing high hygiene standards and introducing contact tracing. The event is also being designed with consideration for the wider economic environment, the economic situation in the AM sector, and developments in the European and global travel industry. Formnext 2020 remains scheduled to go ahead as planned in Frankfurt from 10-13 November 2020.

“We remain convinced of the unique value and advantages of a physical exhibition, and although digital interaction will never be able to replace face-to-face contact, it does offer more scope than previously thought possible only a few weeks ago.” explained Sascha F. Wenzler, Vice President of Formnext, Mesago Messe Frankfurt GmbH.

Business news in 3D printing

3D Systems has revealed that Dr. Jeffrey A. Graves will be its new President and CEO, effective May 26th. Graves joins 3D Systems from MTS Systems, the global manufacturer and supplier of simulations and testing systems, where he served as CEO for the past eight years. He replaces Vyomesh Joshi (VJ), who announced his retirement in February, and brings with him 17 years of CEO experience in addition to a proven track record for leading and operating technically complex businesses.

“I am incredibly excited about the opportunity at 3D Systems. Digital manufacturing will play a key role in the transformation of manufacturing, and 3D Systems is uniquely positioned to help companies benefit from this transformation,” said Graves.

Elementum 3D, the Colorado-headquartered additive manufacturing material developer, has achieved ISO 9001 certification for quality management. Issued via the management certification firm Platinum Registration Inc, the certification includes the design and manufacture of advanced metals, superalloys, and composites, in addition to manufacturing processes and prototype parts. Established by the International Organization for Standardization, ISO 9001:2015 is a globally recognized standard for quality management systems and practices.

“This is an important milestone for Elementum 3D,” said Dr. Jacob Nuechterlein, Elementum 3D President and Founder, “It’s a rigorous process to become ISO 9001 certified. Our staff worked very hard with Platinum Registration’s auditors to demonstrate we meet the requirements of the standard. Not only does that make us feel confident we’re the most efficient that we can be, it assures our customers that we have a completely transparent and robust management system,” he added.

The Auckland-based 3D prototyping company Complete 3D, has become a certified reseller of DigiFabster software in New Zealand. As a platinum reseller partner, Complete 3D will be responsible for all aspects of marketing and implementation of DigiFabster’s software to machine shops and 3D printing service bureaus in New Zealand. Digifabster’s reseller scheme assists equipment, material, and software resellers looking for a way to boost their recurrent revenue, through offering SaaS products such as theirs.

Materialise celebrate milestone for its Dream Bus

Belgian software and 3D printing service provider Materialise, has revealed that over 50,000 students have had the opportunity to board its Dream Bus since the project began in 2015. Working together with the Adream Foundation, the Dream Bus was launched to enable school kids across Western China to learn about and explore what 3D printing can do. Aimed at children aged 7-15 and staffed by volunteers, the high-tech classroom on wheels provides a basic knowledge of 3D printing to students living in remote areas. The volunteers hope to use the bus’ onboard desktop 3D printers to inspire a whole new generation of young people to experiment with the technology. The 17 meter long, 27 ton Dream Bus, has now visited 190 schools in 250 Chinese provinces, covering a total of more than 120,000 kilometers in the process.

“Some children tell us that they want to 3D print human organs to help sick people. Some say they want to print spaceships and flying houses. Some have even said that they want to 3D print vegetation to plant in deserts. Although they may not yet fully understand the principles of this technology, they all have the belief that it can change the world,” according to volunteers from Fujian province, China.

RPM installs two Farsoon 3D printers, Sciaky delivers welding machines to MERRILL

3D printing company Rapid Product Manufacturing GmbH (RPM) has installed two new Farsoon polymer laser sintering (SLS) machines. The 3D printers, installed exactly 23 years to the day since RPM was founded, will produce prototypes and small series parts for German OEMs and their tier supplier network. The Farsoon SS403 3D printer offers the stable but fast production of series parts for direct use applications and quicker prototype iterations. The HT403 3D printer meanwhile, adds high temperature shielding and thermal controls, which are important for applications in the automotive and logistics industries.

RPM will keep some of their old machines to produce parts with special material blends, and to produce models and cores for their plastic casting operations, but they will not feature in the company’s daily production chain.

“When we started RPM in 1997, we were focused almost exclusively on rapid product development using additive and other production methods. Over the years, we have moved further down the production chain, so that now RPM is a single contact point for bringing plastic parts from idea to reality. As soon as they are online and calibrated, the new Farsoon machines will begin printing small series parts,” said Dr. Jörg Gerken, Technical Director at RPM.

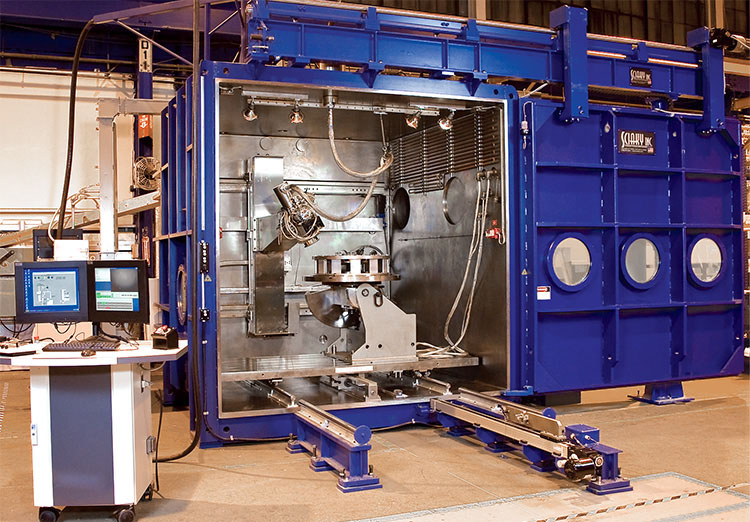

Chicago-based metal 3D printer manufacturer Sciaky Inc, has announced that it will supply Electron Beam (EB) welding guns to the Michigan-based solutions provider MERRILL. The guns’ multi-axis motion operates at half the chamber volume of fixed/external gun systems, providing beam access for unusual joint configurations, and simplifies part tooling. Sciaky’s welding technology is typically used to manufacture items such as airframes, landing gear, jet engines, guided missiles and vehicle parts.

America Makes launches AXIOM Project

America Makes, the Ohio-based national accelerator for additive manufacturing, has announced its next project call to support the U.S. Air Force (USAF). The Additive for eXtreme Improvement in Optical Mounts (AXIOM) project, is seeking novel 3D printing designs to enhance the readiness of high-precision optical components used in sensors, space systems, and other applications. The U.S Air Force Research Laboratory (AFRL) funded project is aiming to award $560K to all the winning designs, with an additional $280K to be awarded to the winning project team, taking the prize total to $840K. The competition is seeking to fund designs that mitigate the costs and delays caused by producing products with complex geometric features, through innovative approaches that leverage AM.

“The AXIOM Project Call represents an incredible opportunity to advance both AM design and materials technologies given the geometric complexity and performance requirements of high-precision optical components,” said America Makes Technology Director Brandon Ribic, Ph.D.

Fragaria’s software turns ordinary 3D printers into ‘smart printers’

Czech software developer Fragaria has launched its Karmen software with the aim of making 3D printers more accessible and convenient to use. The software turns ordinary 3D printers into “smart” printers according to the company, enabling users to manage their 3D print jobs from anywhere in the world. The cloud service is being developed as an open source solution, allowing customers to control their printers from a web browser running on any computer, tablet or smartphone. The software can be used to schedule print jobs, inspect print progress or distribute jobs among printers. It’s compatible with printers featuring a Wi-Fi network adapter or webcam, and the company offers its Karmen Pill controller as an alternative for those that don’t. The Karmen Pill is a tiny box (measuring only 77 x 34 x 12 mm) which enables customers to connect their printer to the local network or to the internet, and to link it up with the Karmen cloud service.

“Unfortunately, the majority of current printers force their users to stick around when they’re not connected to any network and have to be managed and controlled locally. dealing with more demanding print jobs that require multiple hours to finish, this limitation turns out to be rather impractical. More often than one would like, this results in print jobs having to be repeated over and over from the beginning. Thanks to the Karmen cloud service and Karmen Pill controller, this problem becomes a thing of the past,” said Martin Burián, Fragaria’s Chief Executive.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on a Sciaky Electron Beam Additive Manufacturing unit. Photo via Sciaky.