In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across our industry.

Today’s edition features the winners of the 2020 Design for Additive Manufacturing Challenge, Artec 3D’s latest class of gold certified partners, four 3D printed UAVs and even a 3D printed replacement bill for an injured goose called Bruce.

Read on for the latest news from Sonda SYS, Kingsbury, Sintratec, TANIOBIS, Nanofabrica, DMG MORI, PostProcess, RPS and more.

Awards given virtually to 3D printing proteges

3D printing service provider K3D and student Younes Chahid have been revealed as the 2020 winners of the Additive World Design for Additive Manufacturing Challenge. All six finalists pitched their designs via video link for the 6-member jury, with Younes’ ‘hip implants stem’ design winning the student award and K3D’s’ laser welding head winning the professional award.

Younes’ hip implants design is intended to shorten operation times and recovery times. The design of the structure is fully optimized with varying lattice densities and thicknesses for optimal bone ingrowth. K3D’s laser welding head design won the professional award for the second year in a row. The judges were impressed with its strong business case and the applications of the design.

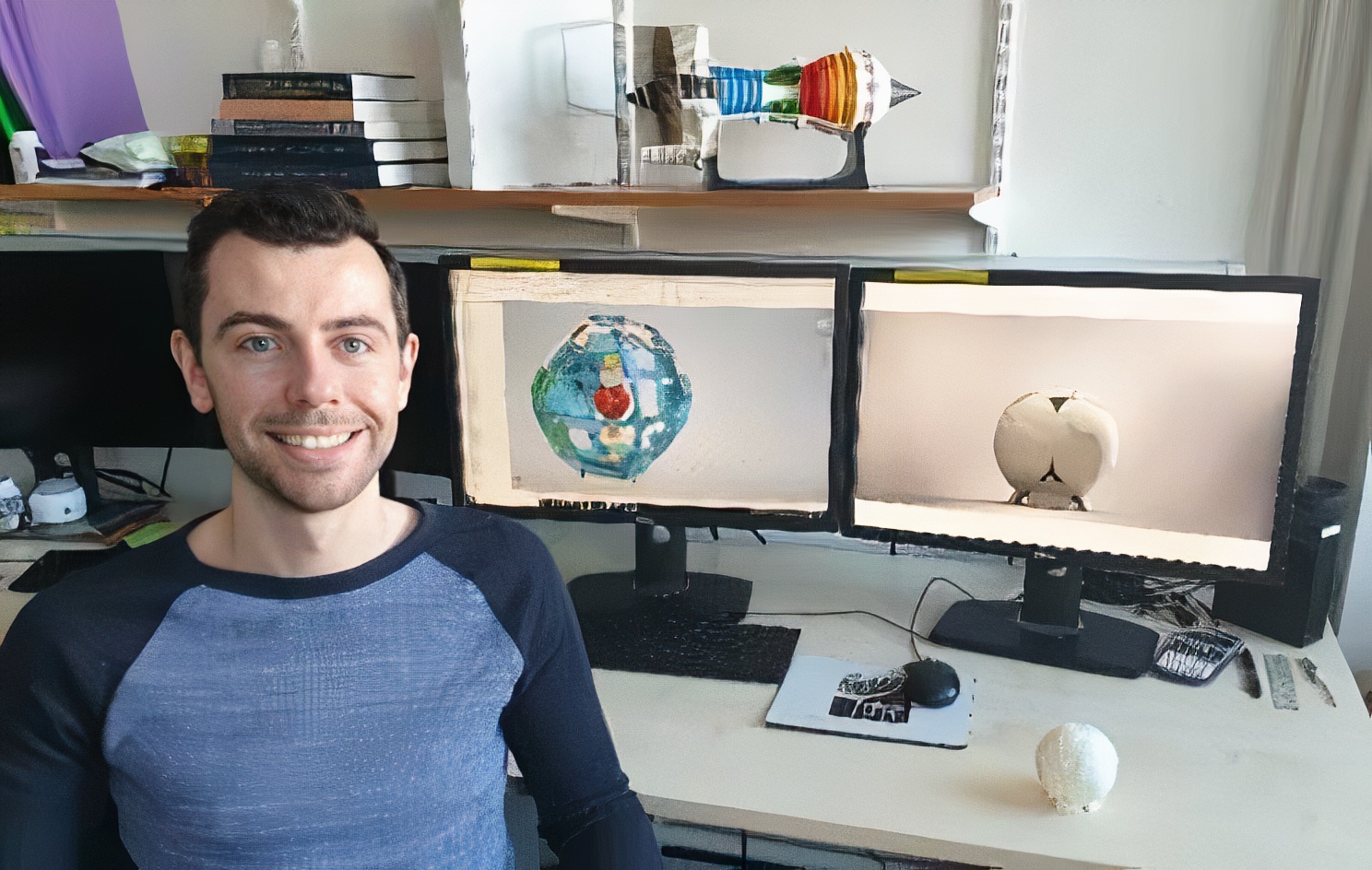

Carrying on with good news stories, Irish PhD student Daniel Fahy won first place in Stratasys‘ annual Extreme Redesign Challenge Awards. Fahy took first place in the ‘art, jewelry and architecture’ category winning a $2,500 scholarship, a free Stratasys FDM 3D printer for his university for a year and a printout of his winning design. Having previously won the same category in 2017, for this year’s competition he utilised 3D printing to recreate a Hoberman Sphere from scratch within just a few weeks.

“I feel privileged to have won this competition. The main reason I entered was because it allowed me to be creative and explore my passion for engineering and design via a project of my own. I’m particularly delighted to have won a Stratasys FDM 3D printer for our university. Having utilized 3D printing throughout the latter years of my education, I believe all students should have access to this technology,” he said.

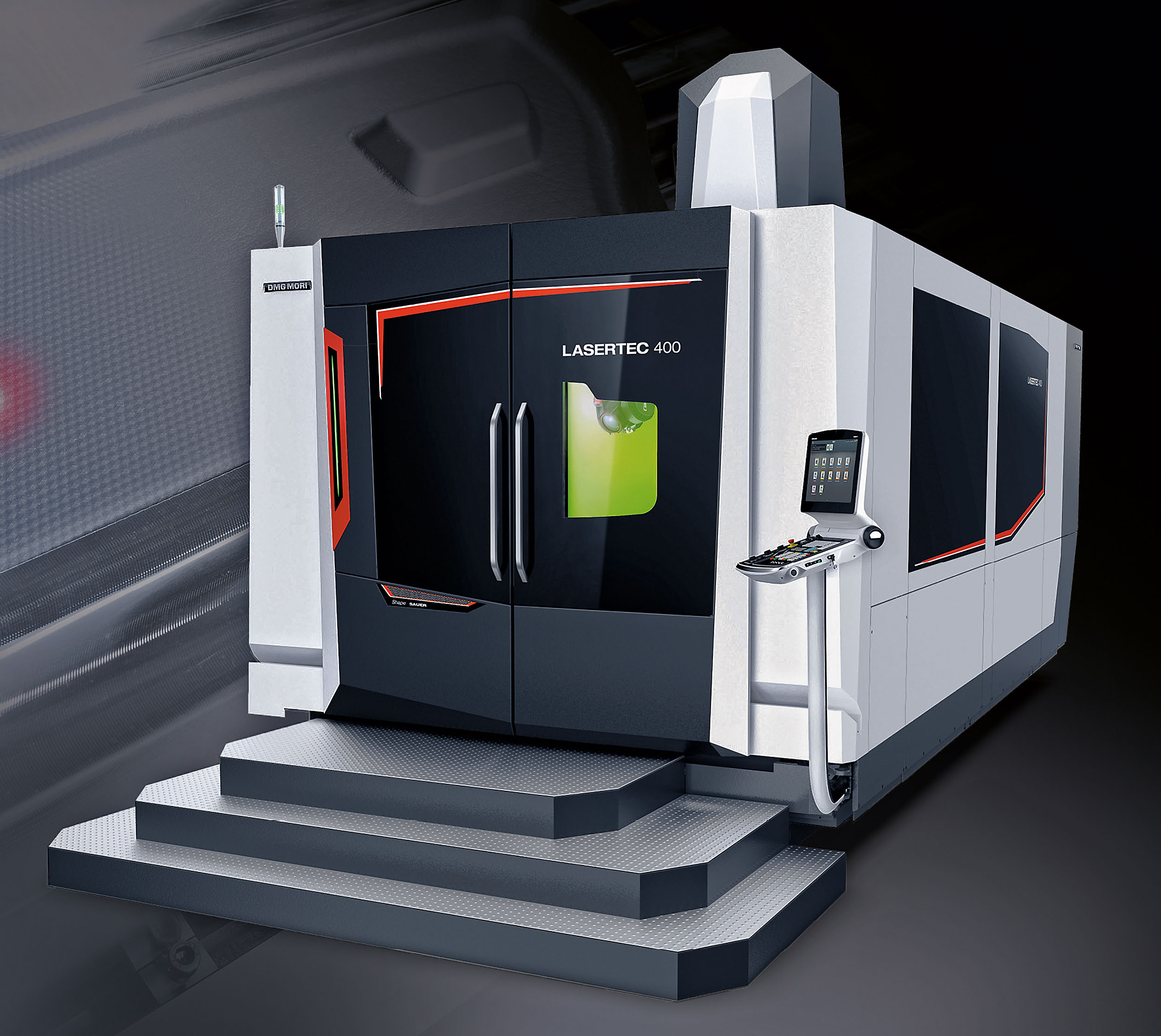

DMG MORI introduce new CNC machine

Leading machine tool manufacturer DMG MORI has launched a new gantry-type 5-axis CNC machine. Designed for the laser texturing of 3D freeform surfaces of moulds, and tools weighing up to 20 tonnes, the LASERTEC 400 Shape is the largest model in its range of four laser ablation machines. It comes equipped with a newly developed additive manufacturing laser head. Designed by DMG MORI to be narrow and compact, it offers accessibility even if a component has deep and narrow features.

Its laser produces 100W of power with a switchable pulse length and a frequency of up to 1 kHz, and a F-Theta scanning lens provides the system with 3D processing optics, allowing it to apply features onto existing 3D surfaces. The printhead has two degrees of movement with ± 200 degrees rotation and a swivel range of -100 to +135 degrees, allowing it to process undercuts. DMG MORI plan to release a further mid-range version of the machine with a 2,000 mm X-axis, the LASERTEC 200 Shape at a later date.

New names and partnerships in additive manufacturing

Materials manufacturers H.C. Starck Tantalum & Niobiu, is being renamed TANIOBIS, with the change effective from July 1st 2020. The change won’t impact on operations at their German, US or Japanese production sites. The company produces materials, powders, and alloys based on tantalum and niobium for a variety of markets including automotive, energy and aviation.

“Our new name is a combination of the two key raw materials used in our production operations, tantalum and niobium. The characters ‘i’ and ‘s’ at the end stand for innovative solutions” explained Masakazu Kanzaki, Vice Chairman & CEO at H.C. Starck Ta & Nb. Polish.

3D printer manufacturer SondaSYS, which specializes in SLS technology, has partnered with Canadian automation company LeoSparq. LeoSparq will now be the first and sole distributor of SondaSYS 3D printers in the US, Canada and Mexico, while also being responsible for all service and maintenance there.

Machine tool specialists Kingsbury has signed a deal with GEFERTEC, the German WAAM (wire arc additive manufacturing) equipment builder, to become the sole supplier of its technology in the UK, Ireland and the Gulf. GEFERTEC develops new methods for producing metallic parts, specifically where parts extend beyond conventional production processes such as in the aerospace and rail sectors.

“We share with them the same vision of long-term cooperation and of offering our customers more than just hardware but efficient production solutions for quantities down to a batch size of one. With Kingsbury’s expertise and passion for manufacturing, we will make the benefits of our award-winning 3DMP technology a success for customers in the UK, Ireland and the Gulf,” said Tobias Röhrich, CEO of GEFERTEC.

New York-based automated post-printing developer PostProcess has announced a new channel partnership with Russia-based 3D printer distributor Z-axis. The deal will expand PostProcess’ network of resellers in Russia, Belarus, Kazakhstan, Kirghizia and Armenia. Israeli-based 3D Alliances will also work with PostProcess to support their recruitment of new European sales partners.

“To better service this expanding market and help us identify strong partners, we are pleased to have the opportunity to work with 3D Alliances. They have already helped us secure a strategic agreement with Z-axis.” said Bruno Bourguet, Managing Director of PostProcess Technologies International.

Industrial 3D printing specialist RPS has partnered with Wisconsin-based service bureau Midwest Prototyping, to bring its flagship NEO800 large-format stereolithography system to North America for the first time.The system has been installed at Midwest Prototyping, and while the machine is an open material system, DSM will be its materials supplier for the machine.

“Moving into the North American market is a key focus of the RPS development strategy. We have been very clear that we wanted to make this step with partners who share our commitment to service excellence and quality,” said David Storey, Director at RPS.

Swiss 3D printer manufacturer Sintratec has announced that it is strengthening its presence in Western Europe by signing a distribution deal with Bender Additive Manufacturing B.V. (Bender AM). The deal with Sintratec will allow the Netherlands-based additive manufacturing subsidiary of Bendertechniek B.V, to distribute Sintratec compact selective laser sintering (SLS) systems throughout the Benelux region. Bender AM will now offer Sintratec’s compact S2 machine in addition to industrial-grade metal and polymer machinery from EOS, Gefertec, Lithoz and 3D-MicroPrint.

Artec 3D has announced its newest Gold Certified Partners. The applicants had to demonstrate extensive knowledge of Artec’s product range to gain the accreditation, and join the other 140 global accredited resellers. Fifty new resellers were accredited, with four companies exceeding customer expectations to achieve ambassador status.

Nanofabrica’s fight against Covid-19, Xometry pledge to go carbon neutral

Israeli 3D printing company Nanofabrica is continuing to support the fight against Covid-19, with additive manufacturers across the industry pledging their assistance.

Nanofabrica says its technology could be used to build structures with ultra-small holes, with the potential to be used in microfluidic applications. The technology achieves high resolution surface textures which can be used to create surfaces that defend against virus transmission. It could also be used to accelerate the production of testing equipment for infection or antibodies.

In environmental news, to celebrate Earth day 2020, U.S. based on-demand manufacturing marketplace Xometry has launched a carbon offsetting initiative. For every custom part its customers order, Xometry has pledged to reduce or completely offset the associated carbon emission, with 100% of any proceeds going to a wind farm in Texas.

Additive manufacturing applications from around the world

A Chinese goose named Bruce made the news this week, after its bill was partially torn off by a raccoon attack. Staff at the animal rescue centre he was taken to, worked with the nearby Bridgeland Technical College to create a 3D printed replacement bill. The students created 3D models to test on the Goose, before using a 3D printer to produce different versions of the bill with Acrylonitrile Butadiene Styrene filament.

In other applications, Panerai’s new limited edition PAM 768 watch not only sports an eye catching bright green flange, it also features a case that was produced using direct metal laser sintering (DMLS). Constructed using grade 5 titanium, the case is 40% lighter than a conventional titanium case.

In India meanwhile, Four 3D printed UAVs (Unmanned Aerial Vehicles) were showcased at the ‘Wings 2020’ event at a prototyping centre in the city of Hyderabad. The UAV was printed and assembled by the government-funded T-Works team, who are now developing the heavy lift aircraft for a government medicine scheme.

Finally, Liverpool-based supercar manufacturer Briggs Automotive Company (BAC) has revealed it is 3D printing parts for its vehicles on an Ultimaker desktop platform in partnership with 3DGBIRE. The collaboration has enabled BAC to print over 40 parts for its single-seater supercars including prototypes and end-use parts.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows two BigRep STUDIO G2 3D printers. Image via BigRep.