Particle-free metal ink producer Electroninks has received investment from In-Q-Tel, the strategic investment arm of the US Intelligence community founded by the CIA, which will help the firm deliver its particle-free conductive inks at scale to its government and commercial partners.

The company doubled up the announcement with the unveiling of its new enhanced particle-free silver ink specifically engineered for use with aerosol jet printing (AJP) processes.

“At Electroninks, we are committed to providing our customers with the highest performing products and solutions to meet the demands of their emerging manufacturing technologies and products,” said Melbs LeMieux, Electroninks Co-founder and President.

“Our new enhanced particle-free silver ink product is compatible with aerosol jet printing technology and allows our partners and commercial customers to meet difficult specifications.”

Electroninks’ particle-free ink capabilities

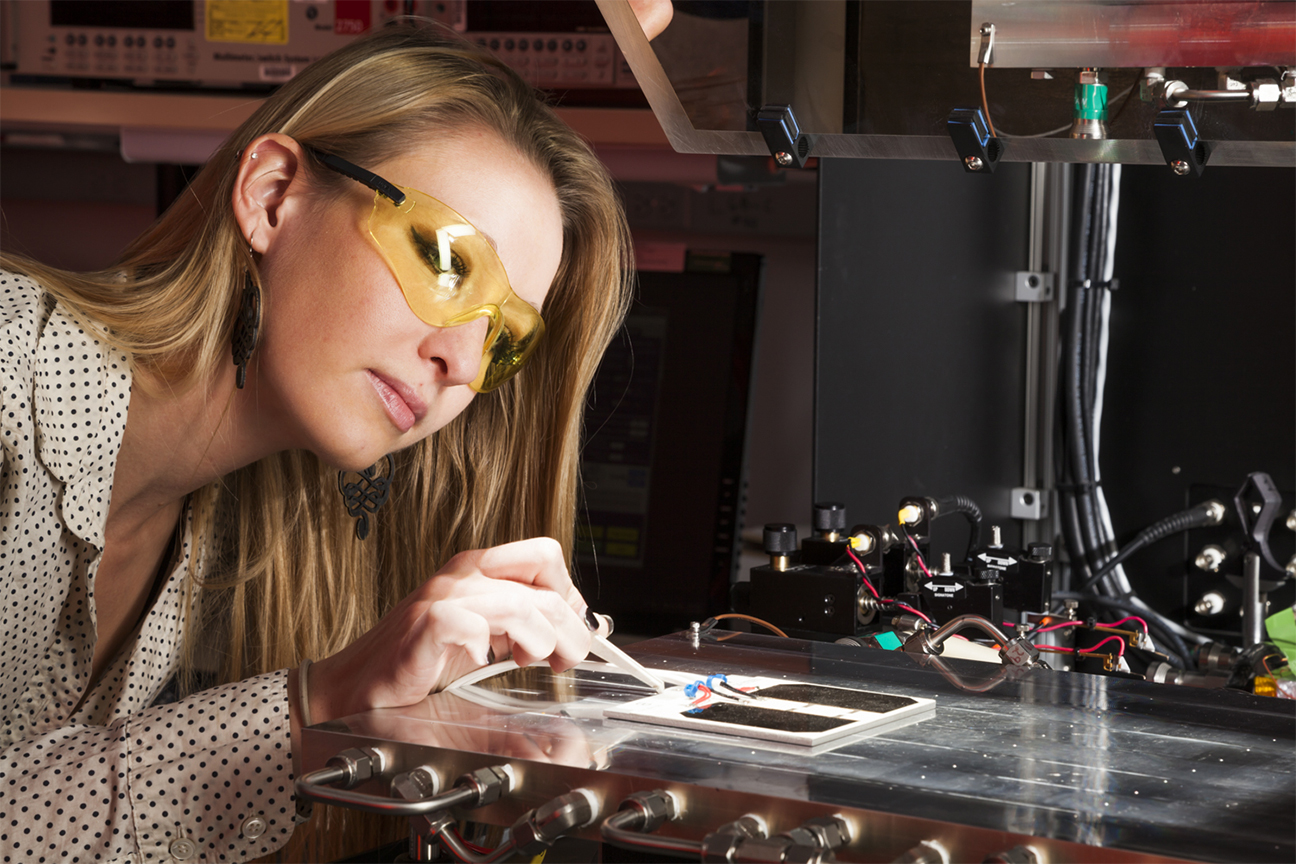

Since its founding in 2013, Texas-based Electroninks has grown into a cutting-edge developer of conductive inks and other products. The firm provides its particle-free conductive inks and related chemistries to industrial customers while also offering its own consumer direct product line, Circuit Scribe.

Based on small-molecule chemistries, the company’s particle-free inks and pastes are engineered to directly replace nanoparticle and flake-based metallic inks and films within electronic devices, displays, interconnects, and wearables applications. The company is reportedly the first to provide particle-free conductive inks in silver, gold, platinum, nickel, and copper.

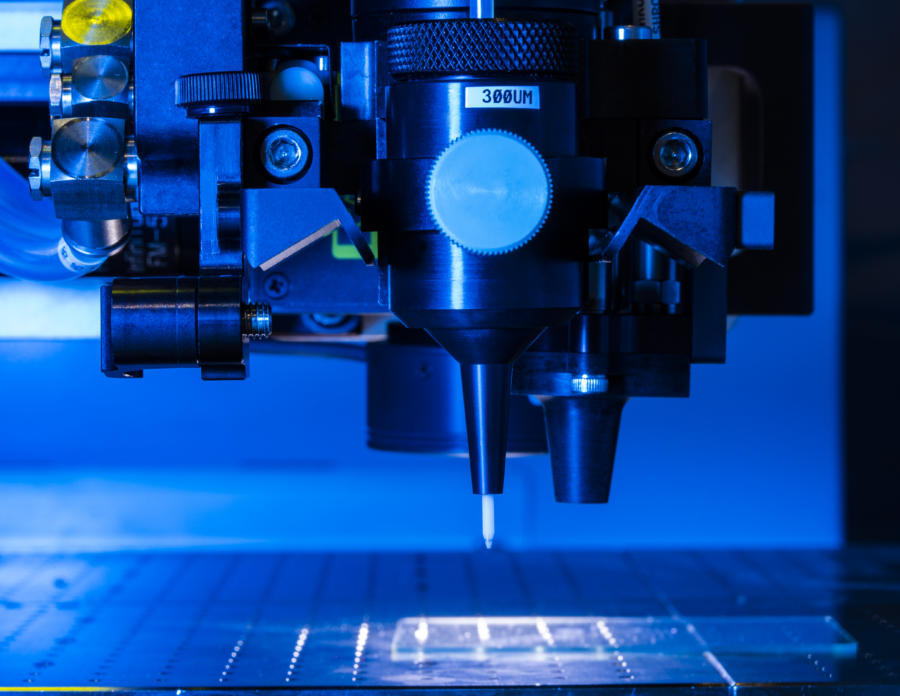

The company’s latest product, its particle-free silver ink, is designed for fine-line, low-temperature curing with AJP in order to provide enhanced print resolution, electrical performance, and process temperature conditions.

AJP, a technology commercialized by 3D printer manufacturer Optomec and a handful of others, enables the 3D printing of commercially available conductive, dielectric, semiconductor and biologic inks onto various 2D and 3D plastic, ceramic, and metallic substrates. The technique is suited to highly-precise electronics applications within semiconductor packaging, displays, aerospace, and biomedical devices.

By engineering its new silver ink to be compatible with AJP technology, Electroninks is seeking to meet the ultra-fine line printing requirements of its customers. Combined with AJP, the particle-free ink, which is ideal for interconnects and metallization within mobile and wearable products, sensors, and displays, will aid manufacturers in reducing the size, power, and weight of their electronic devices.

“The newly-developed ink combines best-in-class electrical performance with fine feature printing,” said Garret McKerricher, Senior Scientist at Electroninks. “The ink is capable of ultrasonic aerosol jet printing and demonstrates fine feature printing at less than 20um resolution with high aspect ratios.”

The particle-free silver ink can be 3D printed at a resolution lower than 15um with up to 10um height, and up to three times the bulk conductivity of silver. The ink can be cured at no higher than 120 degrees celsius while maintaining certain manufacturing and throughput specifications.

“The new silver ink provides good resistivity at a low curing temperature, and has high volume output,” added fellow Senior Scientist Yuan Gu. “Combined with room temperature printability, the ink is ideal for 3D surfaces printing on wrap-around and other flexible surfaces.”

Catching In-Q-Tel’s attention

Electroninks’ novel particle-free formulation and its capabilities have caught the eye of several players in the electronics 3D printing space. For instance, the firm has previously entered into a strategic partnership with the US Department of Defense (DoD) and received a $1.5 million contract from the US Air Force (USAF) last year to develop inks and 3D printers for PCB 3D printing.

Electroninks has also teamed up with various industry partners, including materials engineering firm Applied Materials, global pharmaceutical company Merck, and multinational conglomerate FujiFilm.

The potential of Electroninks’ particle-free conductive inks has now captured the imagination of the US intelligence community, with its venture capital arm In-Q-Tel joining with the firm as an “additional strategic partner and investor.”

According to the partners, the alliance will enable Electroninks to scale up the delivery of its inks and other products to its government partners in national security, as well as for broader commercial use. The amount invested in Electroninks by In-Q-Tel, as well as the fine details of the agreement, have not yet been disclosed, however.

“In-Q-Tel understands the value that Electroninks’ technology and team know-how can provide to the manufacturing of interconnects,” said Victoria Chernow, Technology Architect at In-Q-Tel. “We believe our strategic investment in Elektroninks will contribute to our partners’ mission needs.”

In-Q-Tel has previously shown an interest in the potential of 3D printed electronics, having backed digital manufacturing firm Voxel8 back in 2015 to develop its desktop platform for 3D printing electronics and other multi-material objects.

Investing in electronics 3D printing

Since launching the Manufacturing Innovation Institute for Flexible Hybrid Electronics in 2015, the DoD and other US defense agencies have shown increasing interest in the field of 3D printed electronics, particularly in recent years.

For instance, the Air Force Research Laboratory (AFRL) entered into a cost-sharing agreement with Netflex, a US consortium dedicated to advancing 3D printed Flexible Hybrid Electronics (FHE), in 2020. As part of the deal, the DoD is providing up to $154 million worth of investment over seven years to fund the development of 3D printed electronics to support military operations.

Meanwhile, last year saw the announcement that micro dispenser manufacturer nScrypt’s all-terrain nRugged 3D printer was to be deployed within various DoD initiatives, while USAF contracted circuit board fabrication specialist BotFactory to develop a fully-automated desktop electronics 3D printer as part of its ‘AFWERX’ program.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Electronink’s particle-free silver ink is compatible with AJP processes such as Optomec’s. Photo via Optomec.