Regenerative medicine specialist CollPlant has partnered with BICO firm CELLINK in an effort to ramp up its production of 3D bioprinted breast implants.

Currently undergoing preclinical trials, CollPlant’s bioprinted grafts are designed to degrade over time and be replaced by native tissues, in a treatment that could prove much safer than traditional augmentation procedures. In an effort to scale the production of these grafts, the firm has now begun working with CELLINK, in a partnership with the potential to unlock a market it values at $2.8 billion.

“We are thrilled to be working with a partner who shares our values and passion to create the future of health,” says Cecilia Edebo, CEO of CELLINK. “We look forward to making an impact in the breast implant industry but also to developing a long-lasting relationship with CollPlant, characterized by advancements in the wider field of tissue engineering and regenerative medicine.”

rhCollagen-based bioprinting

According to CollPlant, the fields of regenerative medicine and tissue engineering have undergone “unprecedented growth” in the last decade, with 3D bioprinting starting to gain traction as a means of creating viable, transplantable organs.

The company’s own deployment of the technology revolves around its tobacco plant-grown alternative to animal or cadaver-sourced collagen transplants. Known as ‘rhCollagen,’ this recombinant protein can be processed into something akin to the type I collagen produced by the human body, that can be implanted with a reduced risk of rejection, making it an ideal regenerative medicine building block.

In the past, CollPlant has worked with United Therapeutics to 3D bioprint rhCollagen into transplantable lung transplants, as part of a collaboration that was later extended to the production of kidneys, as well as 3D Systems, to create both tissues for third parties and ‘integrated 3D bioprinting solutions,’ composed of bioprinters and bio-inks.

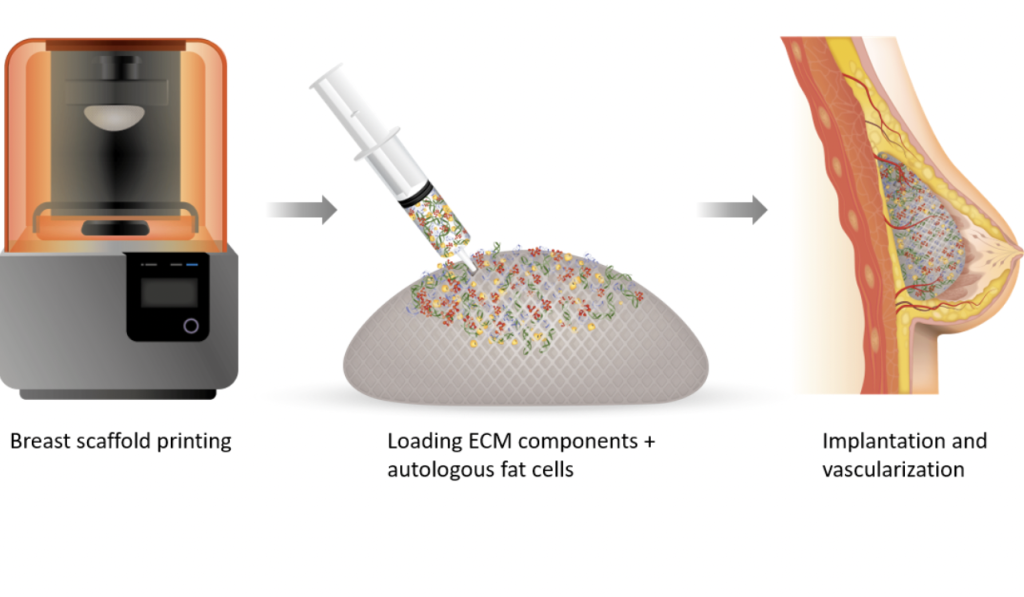

Back in 2019, CollPlant also announced the development of its first regenerative breast implants. Made up of rhCollagen, patient fat cells and ECM components, these tissues are bioengineered to promote cellular regeneration once injected into those seeking breast augmentation or reconstruction, before gradually degrading, in a procedure that’s designed to leave behind no foreign contaminants.

Although not yet commercially available, CollPlant says that its breast implants could represent a “revolutionary alternative” to silicone implants or fat transfer operations, which come with a ‘risk of adverse events’ and ‘volume-loss limitations.’

Scaling implant production

To accelerate the production of its regenerative breast tissues, CollPlant has now partnered with CELLINK, one of the early leaders in the 3D bioprinting field. As such, CELLINK has embarked on an expansion of its own over the last two years or so under the BICO umbrella, as part of a wider strategy to seek out the synergies between biologics and advanced technologies, that it terms ‘bio-convergence.’

This approach has seen BICO acquire precision dispensing firm Scienion for €80 million, buy Nanoscribe for €50 million, a known 2PP 3D printing specialist, and spend $68 million taking over the MatTek Corporation to expedite its animal-free drug testing model R&D.

Since its parent company acquired these different technologies, CELLINK has managed to integrate some of them into its already-impressive 3D bioprinting offering. Alongside its extrusion-based BIO X, BIO X6 and INKREDIBLE+ systems, the firm now markets the light-based Lumen X+ and Quantum X bio, with the latter incorporating Nanoscribe 2PP to unlock ultra-precise cell deposition.

Utilizing these “high-throughput bioprinters” and the technical expertise of CELLINK’s team, CollPlant says that it aims to overcome the final hurdles facing its implant R&D. Marking its second such partnership in less than a year, after it agreed to develop breast reconstruction treatments with 3D Systems last July, the firm adds that its latest deal will expedite the process of bringing its implants to market.

“We’re very pleased to enter into collaboration with CELLINK, a recognized leader in the development of 3D bioprinting solutions for the life-science industry,” adds CollPlant CEO Yehiel Tal. “We believe CELLINK’s high-throughput bioprinters and biofabrication expertise will help us move toward the successful commercialization of our technology and deliver a much-needed solution to patients.”

Breast tissue bioprinting advances

Whether developed as a treatment for cancer survivors or an alternative to augmentation procedures, 3D bioprinted tissues continue to take strides towards clinical viability. Just last month, French start-up Healshape managed to raise $6.8 million towards its development of custom 3D bioprinted breast implants based around living patient cells.

Similarly, Korean biotechnology firm Plcoskin revealed in July 2021, that it was set to lead an international research project focused on the creation of novel biodegradable breast tissue grafts. The program, which has seen the company begin working with Yonsei University and medical device coating specialist LipoCoat, has received European Commission backing to the tune of $1.7 million.

Elsewhere, 3D printing is also commonly used to produce patient-specific surgical guides, designed to allow female cancer survivors to retain more of their breast tissue following mastectomies. At Asan Medical Center, for instance, scientists have managed to develop devices that enable surgeons to save tissue up to 1cm from the sites of tumors, before using them to treat real, early-diagnosis patients.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D bioprinted soft tissue scaffold developed by CollPlant alongside 3D Systems. Photo via 3D Systems.