A research team from the Jacobs School of Engineering at UC San Diego has used 3D printing to make a glove for a richer virtual reality (VR) experience. Powered by water, the soft robotic hands give tactile feedback to create the feeling of playing a digital piano.

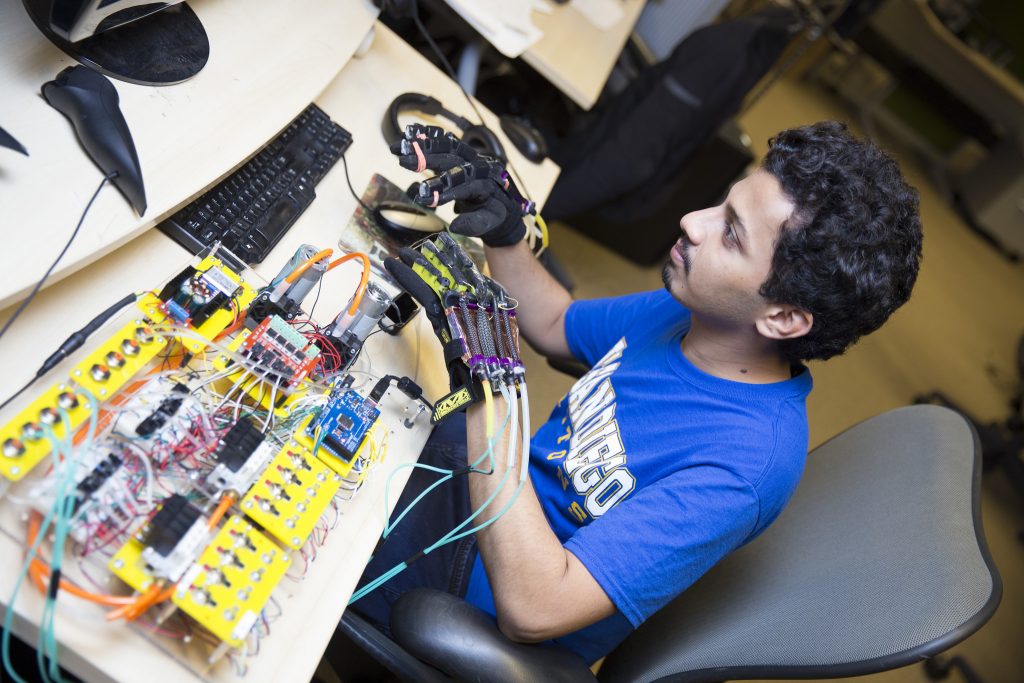

A student at UC San Diego tries out the soft robotic gloves. Clip via JacobsSchoolNews on YouTube

Next level virtual reality

Devices used in connection with VR headsets are typically a kind of controller that has to be held by the user, as tried by 3D Printing Industry at the UK Intelligent Engineering Forum 2017 and more recently at 3D Printing Industry HQ last week. The thought behind UC San Diego’s gloves is to make these devices feel more natural, as explained by Jurgen Schulze, a researcher at the Qualcomm Institute at UC San Diego.

In relation to existing wearable VR devices, Schulze says,

They’re not realistic. You can’t touch anything, or feel resistance when you’re pushing a button. By contrast, we are trying to make the user feel like they’re in the actual environment from a tactile point of view.

How is it made?

As a first prototype, the glove is made from an arrangement of latex cylinders that fill with water when movements are made in relation to the keyboard. The latex cylinders are attached to a rubber silicone exoskeleton, created by the team using a 3D printed mold.

Activation of a fluidic latex chamber in the UC San Diego hand. Clip via JacobsSchoolNews on YouTube

To develop the glove, UC San Diego engineers are looking for ways to make the design more compact and inexpensive to produce.

One option for improving the production of the gloves could be to directly 3D print the soft and hard parts of the exoskeleton in one operation, though this would require the use of multimaterial 3D printer. The material used to make the legs of an all-terrain walking robot at the The Jacobs School of Engineering could be useful in this effect.

The engineers could also look to a more efficient way of embedding motion-sensing into the glove, as in the minute bionic sensors from the McAlpine Research Group at the University of Minnesota.

Not just a toy

More than just a toy for experimenting with virtual experiences, such gloves could also become a part of digital reality development on a industrial scale.

As previously reported on 3D Printing Industry, Chicago’s manufacturing innovation accelerator UI LABS and the Augmented Reality for Enterprise Alliance have collaborated to develop the world’s first augmented reality (AR) guidelines for industrial use. AR startup DAQRI is also proving the market for interactive reality devices with its industrial use Smart Helmet. It’s feasible then that the Jacobs School of Engineering’s glove could be integrated with such systems, to enable a remote and practical approach to part inspection and design.

To stay up to date with 3D printing’s integration into VR systems and other news sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image: The VR robotic glove from UC San Diego. Photo via jsoe on Flickr