As 3D models for additive manufacturing are held digitally, whether as CAD files, .stl or another format, the 3D printing industry will be closely linked to Industry 4.0’s ‘Big Data’. With such a vast array of information, platforms are evolving to help businesses turn this data into a connected workflow and a strategy that works for them.

3DEXPERIENCE from Dassault Systèmes (EPA:DSY) is one such solution, providing a host of integrated CAD, co-operative workspace solutions and more for businesses. The 3DEXPERIENCE was a central part of 2017’s UK Intelligent Engineering Forum (UKIEF) in Coventry this week. Hosted by product lifecycle management (PLM) system provider Intrinsys, 3D Printing Industry attended the event to learn more about what Big Data means for additive manufacturing and the movement towards mass customization.

A virtual experience of product design

As a key partner at the event, Dassault Systèmes exhibited a range of demos for the 3DEXPERIENCE. These apps include the primary CAD modeling Caita program, based in the cloud, and mixed and immersive VR experiences of design, optimized for use with HTC Vive.

Other VR design exhibitors included a platform from Lenovo ThinkPAD, and HoloLens integration from product data interoperability and CAD/CAM solutions providers Theorem Solutions.

Following a demo of the Theorem Solutions software, representatives explained to me how such mixed reality options can also be used alongside physical 3D prints. As such tech would typically be used for walkthroughs of a design, the 3D visualizations can also be applied to physical models to test compatibility.

Theorem explained that compatibility between the digital and physical models of an object is essential to additive manufactured parts. Poor translation between the two is one of the challenges facing the 3D printing industry today.

The death of the .stl?

Mathew Favell, customer solutions manager for additive manufacturing at Renishaw, spoke at UKIEF about the challenges to data integrity of 3D models in Design for Additive Manufacturing (DfAM). Sharing a popular opinion on the outdated .stl file he says,

What we call the .stl format has actually reached the end of its usefulness. And actually, I would suggest that when it comes to placing faith in a file format, that really should be at the forefront of digital manufacturing revolution, it is actually causing issues in the way we go forward. It was never designed for series production. It was literally designed just to get the technology moving.

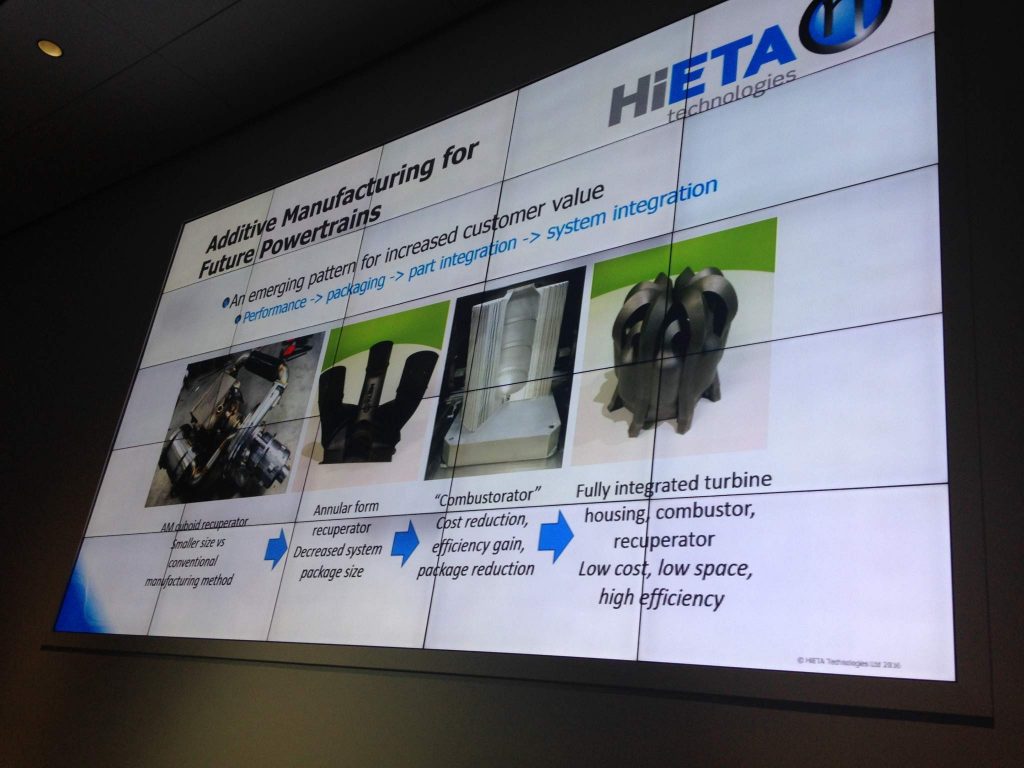

Renishaw customer HiETA Technologies, a company specializing in optimizing weight and thermal dynamics through additive manufacturing, presented several use cases showing how 3D design can overcome the limitations of the .stl format.

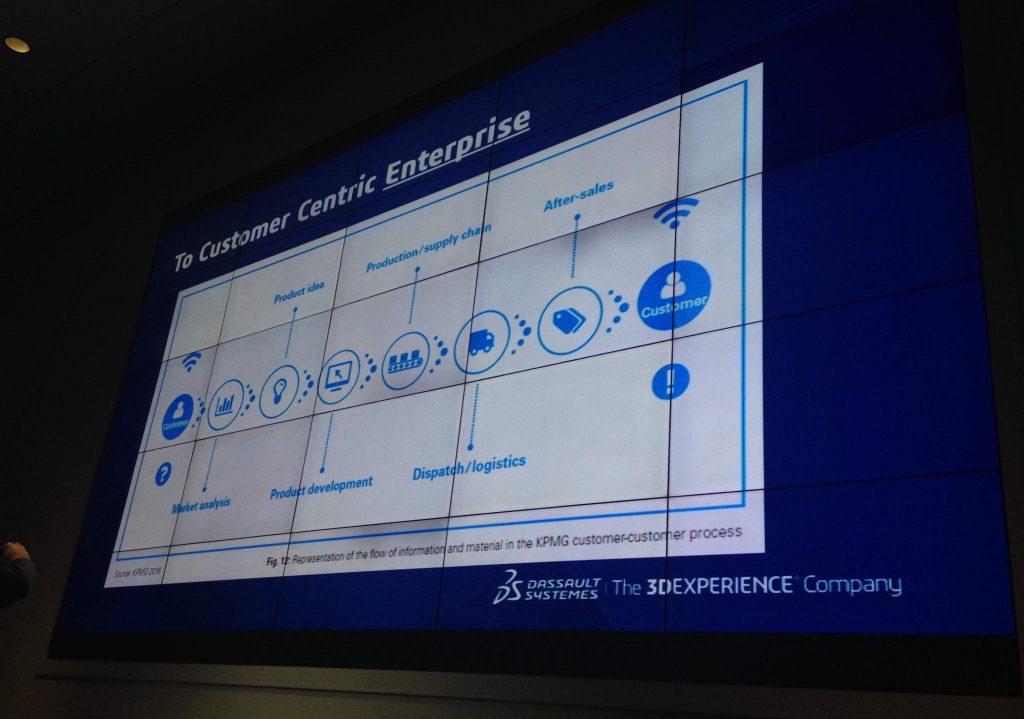

Ben Farmer, HiETA strategy and program lead, also explained how additive manufacturing solutions are contributing to a more “customer centric” approach to business.

The rise of customer centric business models

In an environment where basic products can be consistently undercut by cheaper methods of production, a way for enterprises to maintain leadership is through the provision of custom products.

Additive Manufacturing can facilitate production of such bespoke goods. Germany’s Fraunhofer, for examples, are one company already taking the mass customization intitaive.

While the product lifecycle is becoming more customer centric, it is essential that all parts of that process are in communication with each other. Keeping this in mind, the resulting volume of data must be managed in an efficient manner.

For more on the UKIEF and events like this, sign up to the 3D Printing Industry newsletter, and follow our active social media channels.

Featured image shows Intrinsys Sales Director Craig Mills introducing the 2017 UKIEF. Photo by Beau Jackson.