Fraunhofer Institute for Computer Graphics Research IGD in Darmstadt, Germany, is working on a 3D design solution that simulates the viability of 3D printable objects.

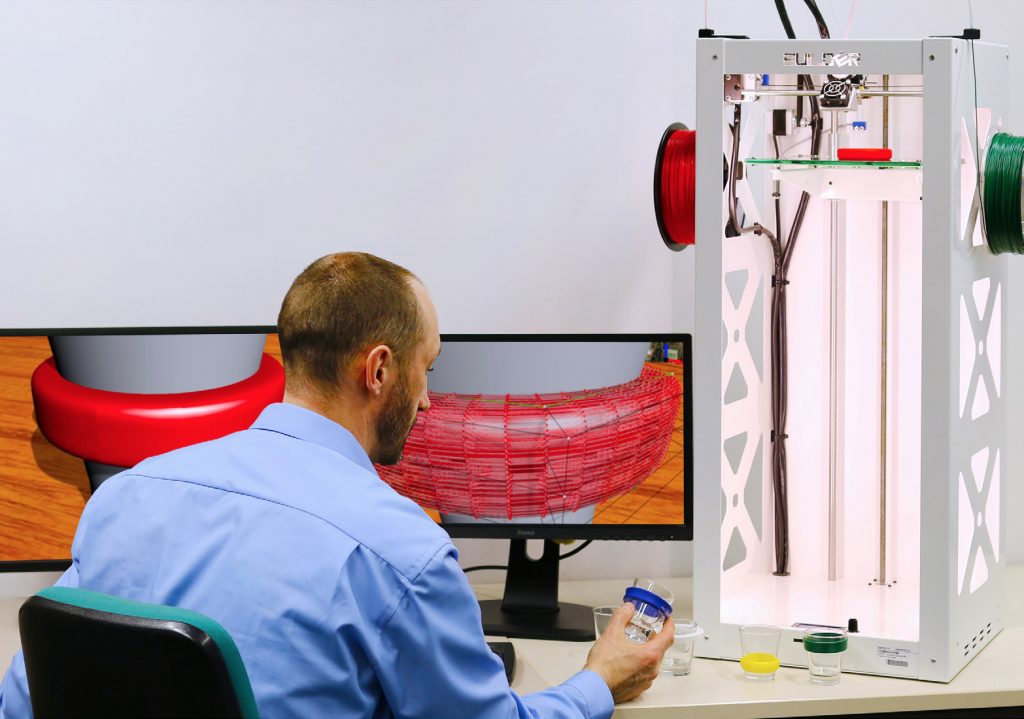

The “Go Beyond 4.0” concept is designed by Fraunhofer to test the viability of CAD models before they reach the 3D printer. It facilitates the opportunity for mass customization in 3D printing – where a customer applies their design preferences on a base object such as a coffee cup, or a pair of sneakers.

Going beyond the surface of objects

All too frequently, the information contained within a 3D model, as in an .stl, or .obj, is not adequately translatable into a 3D print. If the internal geometry is not adequately optimized, i.e. there are structural clashes or holes, an object, though seemingly perfect on the surface, will fall flat of the end goal. Frauhofer’s solution is designed with this in mind.

The institute’s Christian Altenhofen explains the concept as follows,

We create a smooth transition between design and simulation. How to quickly determine whether an individual design can be implemented is frequently an unresolved problem in industry today. In most cases, CAD data only describes the outer surface and does not contain the volumetric information required for simulations. Generating these afterwards is highly prone to errors, usually requires manual reworking and costs the industry a lot of money.

Such solutions are highly prized within the industry as more manufacturers are looking towards 3D printing for the answers to bespoke design. As is the case with luxury car manufacturers Rolls-Royce.

Proof of concept coffee cup holders

Fraunhofer will demonstrate “Go Beyond 4.0” at Hannover Messe 2017 trade show April 24 – 28. At the show visitors will be asked to design their own plastic holders to surround espresso cups. If the software finds incorrect parameters within the design, it then prompts the user of sufficient changes to fix the issues.

Looking further into Industry 4.0 and the Smart Factory of the future, Fraunhofer is also developing concepts for the operation of robotic arms. Having increasing use for part inspection and construction, Fraunhofer are finding ways to make robotic movements safer when in close contact with humans.

To stay up to date on the developments of 3D design and 3D printing for Industry 4.0 sign up to the 3D Printing Industry newsletter, and follow our active social media channels.

Readers can also vote for the best in innovation in the first annual 3D Printing Industry Awards.

Featured image shows the custom designs of 3D printable model cups, from One Coffee Cup a Day | 30 days, 30 cups challenge by Bernat Cuni of Cunicode Design Studio