In this edition of Sliced 3D printing news, we feature: Stratasys, Concurrent Technologies Corporation, Coventry University, Roland DG, Blackbelt, Oerlikon, Artec, NASA, and Cirque du Soleil.

Stratasys to present 3D printed potential at Paris Air Show

US 3D printing company Stratasys has announced it will demonstrate the application of 3D printing interior aircraft parts. The company will join a number of others in the additive manufacturing industry at the event between the 19th – 25th June.

Oerlikon to present metal in Paris

Swiss company Oerlikon has announced it too will be present at the Paris Air show demonstrating its capabilities, including metal 3D printing. The company will also showcase surface solutions to improve the durability of aircraft components. German research institute, Fraunhofer has just unveiled its latest 3D printing innovation that intends to improve the protection of metal parts.

Oerlikon recently partnered with two research institutions to advance its additive manufacturing knowledge, after also opening a dedicated facility in North America.

Coventry University partners with Roland DG

Coventry University has partnered with 3D printer manufacturers Roland DG to incorporate the company’s machines at the newly opened National Transport Design Centre (NTDC). The centre will acquire 3D printers from Roland DG’s DGSHAPE subsidiary.

The partnership will also include the incorporation of the Roland DG Academy and Joe Wigzell, Academy and Creative Centre Manager at Roland DG, said,

Our partnership with Coventry University is a great opportunity for Roland DG. We get a fantastic new space to run our future courses, providing us with a new location for the convenience of our customers. And of course, seeing our machinery used in such a state-of-the-art facility to develop impressive products is a testament to the technology.

Concurrent Technologies Corporation invests $1.2 million into AM

US non-profit organization Concurrent Technologies Corporation (CTC) has invested $1.2 million into additive manufacturing with recent equipment acquisition. To be incorporated at its Pennsylvania facility, is a VRC Metal Systems Gen III Max Cold Spray system and a AMBIT™ Hybrid Additive Manufacturing multi-task system. The company can now offer clients cold spray, hybrid additive manufacturing, and powder bed 3D printing processes.

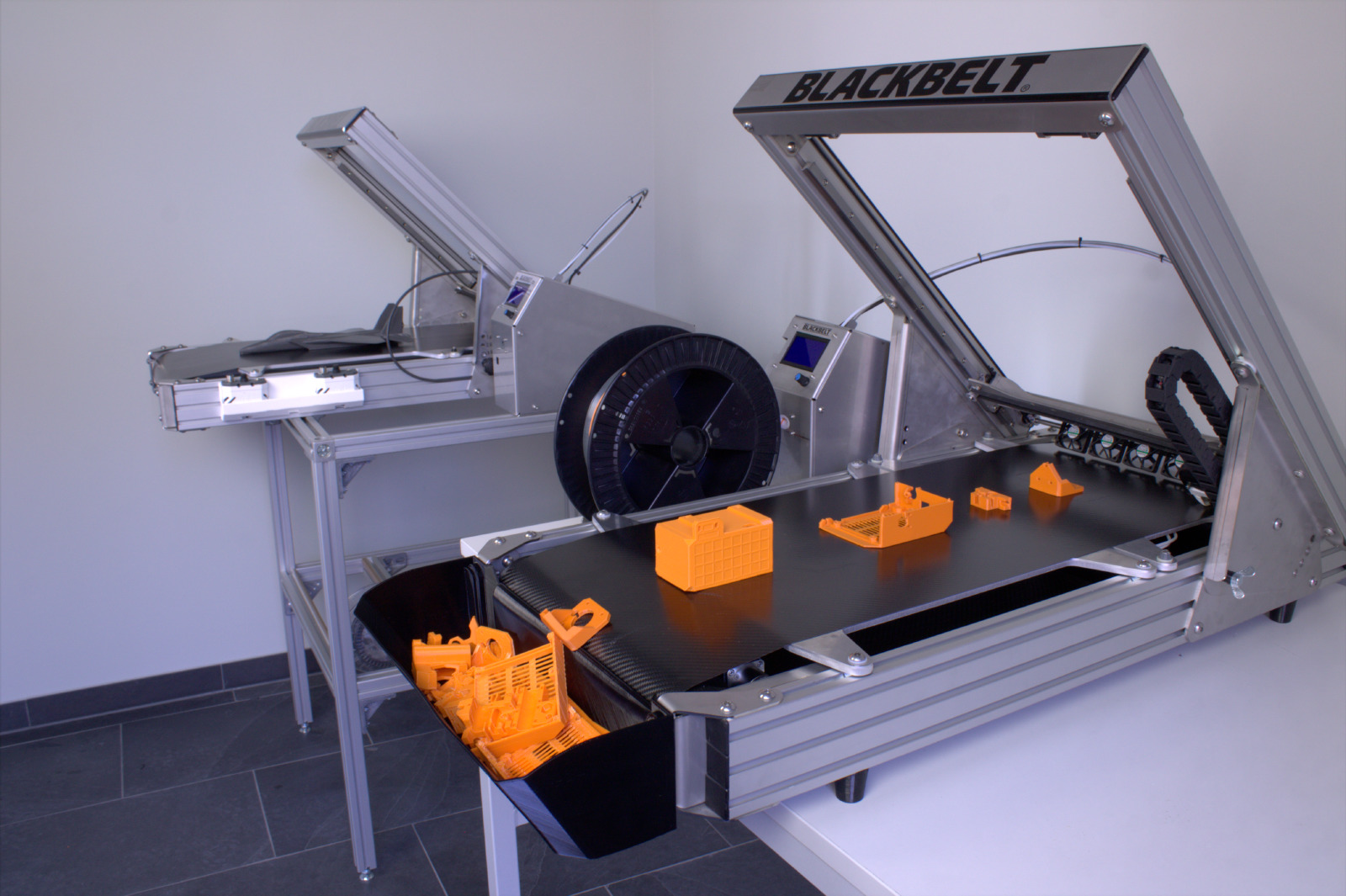

Blackbelt 3D printer reaches goal in 15 minutes

The Blackbelt 3D printer, which uses a carbon fiber conveyor belt to produce unusually long parts or large batches of 3D prints has reached its Kickstarter goal of €50,000 in just 15 minutes after launching. As a result, the Super Early Bird priced 3D printers, at €5,500 are no longer available. However, the crowdfunding pages has plenty of other options for backers with 28 days to go.

NASA uses Artec 3D scanners to create virtual space reality

In its latest innovation to improve training practices, NASA has implemented 3D scanning to create convincing virtual reality environments. Using Artec 3D scanners, NASA has created virtual replicas of some of the tools the astronauts may use in space. This is then combined with virtual reality in order to provide an accurate simulation for training astronauts. The concept is particularly important to allow astronauts to experience how they will work in space since the absence of gravity is difficult to reproduce prior to launch.

NASA launches 3D printed Mars rovers

The end of May 2017 also marked the launch of NASA’s Black Brant IX rocket on a payload mission. The cargo aboard the rocket this time includes the 3D printed mars rover designs from 30 Virginia Tech students and one from Central Florida.

Cirque du Soleil gets first touring 3D printer

The costume department of Cirque du Soleil’s Koozå show has got its first 3D printer in Perth. In an interview for The West Australian Jason Brass, head of wardrobe for the show, explains how the printer has managed to cut down the cost of props and costumes on stage.

As an example, a plastic crown previously used on set would have to be remade up to three times a year. Now, by 3D printing it in a more flexible material, the crown doesn’t break when dropped and can last up to 3 years. Instant production capabilities also gives the costume team on-demand capabilities.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows Sliced logo over the lounge of Black Brant IX sounding rocket, containing 3D printed Mars rover concepts from Virginia Tech and Central Florida. Original photo credit: NASA/Allison Stancil.