This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

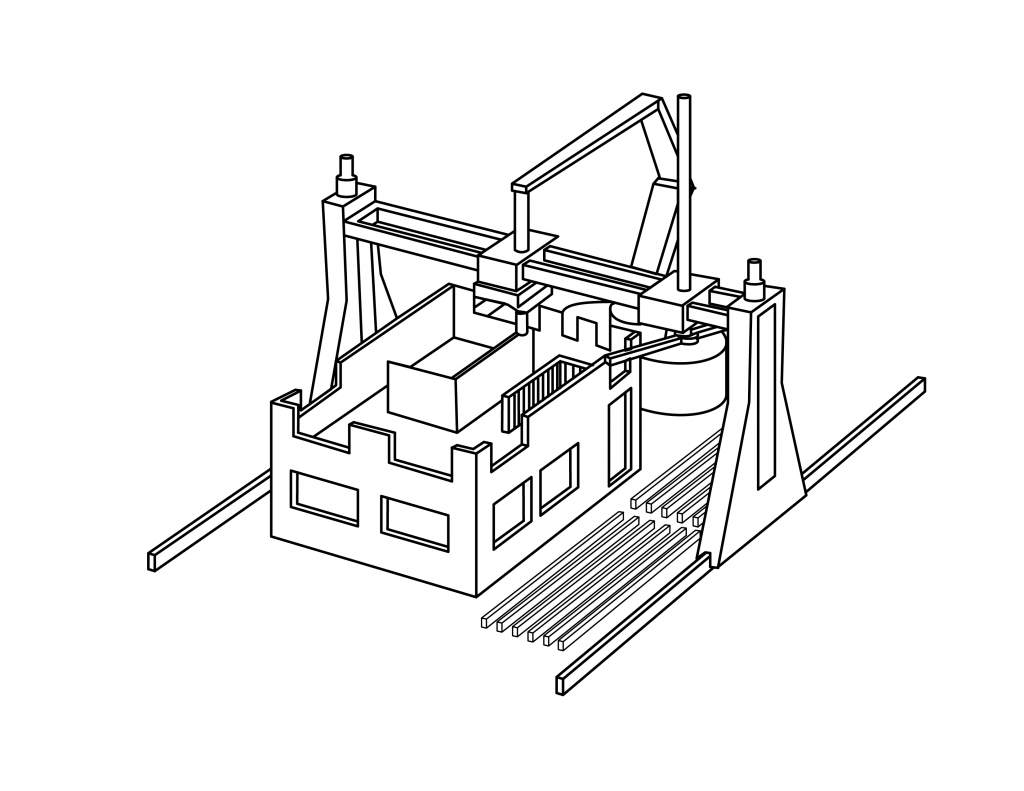

Armatron Systems are a new innovative Full-Scale 3D House (structure) printing company with an extensive patent pending portfolio. Brian C. Giles is CTO, and Blair Souter COO.

3D Printing the next 5 years by Brian C. Giles and Blair Souter

Full-Scale 3D House printing is now poised to transform the construction industry. But how is that set to play out over the next five years?

Here at Armatron Systems, we foresee early adaptations of this technology taking advantage of its flexibility and “on-site” capabilities, constructing a wave of one-of-a-kind, high-end homes, incorporating influences from nature, castles, temples like the Taj Mahal, and Arabian Nights-style structures, that will redefine modern architecture. Expect to see the first such structures printed within the next nine months to a year, most likely in the Middle East.

3D house printing technology will become the new standard

As the technology evolves and becomes more efficient, economical, and available, it will increasingly be employed in mainstream projects, such as housing, film sets, and architectural features. We anticipate that, simultaneously, 3D printers will be employed in the construction of large-scale projects like skyscrapers, stadiums, and amusement parks.

The World needs new housing, fast

Predictions suggest that the global construction market will grow approximately 85%, to $17.5 Trillion, by 2030 (15% of the world output), which means it’s an industry ripe for significant innovation.

The United Nations has stated that we need more than 1 billion homes around the world by 2025 to accommodate more than 50 million new urban dwellers per year.

Additional pressure from national imperatives, for example Brownfield redevelopment and the American Fair Housing Act, adds to the urgency of the demand for rapid and affordable construction of housing and infrastructure.

Construction is labor intensive and dangerous

The construction industry is statistically the most dangerous for its workers, who are increasingly forced to work alongside heavy machinery. Labor costs are exceptionally high, productivity is low, and the sector simply hasn’t evolved in line with manufacturing and other comparable industries.

We see 3D Construction Printing (additive layer-wise manufacturing) as the impetus that will bring the construction industry into a new era of efficiency and profitability.

The 3D construction industry will develop industry standards

The industry is currently moving towards a clearly defined set of criteria that will allow for side-by-side comparisons of the available technology, as we have previously seen in the computer industry.

Here at Armatron Systems, we see the long-term application for customized 3D printing to be onsite construction, in real time, taking full advantage of the speed, accuracy, flexibility, and cost-savings of 3D printing.

For that to happen, most of the 3D printing systems entering the market have some hurdles to overcome. They include the following;

An external gantry larger than the structure to be constructed. The 3D printer itself often requires a crane and significant assembly time.

The printing system being limited to one operating platform and not being scalable.

Requiring complex and proprietary cementitious mixes.

Requiring manual labor for an aesthetically pleasing surface finish.

Needing human intervention for piping, conduit and electrical systems.

Inability to print foundations

Inability to print roofs

Being limited to straight vertical walls (compression), which rules out domes, arches, curved surfaces and more.

Printing pre-fabricated components off-site, which brings logistical costs and simply isn’t as efficient as onsite Full-Scale 3D House printing.

It all boils down to Intellectual Property

As we solve these problems, behind the scenes, companies will compete for intellectual property, the possession of which will determine the successful players. As a computer analogy, who owns DOS?

Over the next six to twelve months we expect to see an influx of startups and multinational companies attempting to enter 3D house-printing, much as we saw with desktop 3D printing. The cumulative effect of IP lawsuits, corporate acquisitions, and mergers should thin the herd to a few key players.

To the victors, will go incredible spoils

The remaining few will then have an incredible opportunity, everything from repairing, retrofitting and refurbishing existing buildings to constructing structures that are almost beyond the scope of our imagination today.

The Full-Scale 3D Construction printing industry will additionally provide seismic upgrades to existing structures and shrink the cost and environmental impact of the construction industry globally.

3D printed construction is the greener option

Every part of the architectural paradigm will be reconsidered. This freedom, together with the significantly reduced waste of Full-Scale 3D printing, will allow the production of sustainable, near zero-energy-point, structures, lasting far longer than a traditionally constructed house.

In addition, decreased construction time will simplify the inspection process and facilitate securing construction and mortgage financing.

Don’t expect 3D printing to bring the housing market crashing down, but it will have a revolutionary impact on the way we all live and work in the not too distant future. Like you, we can’t wait to see how it all plays out.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about Armatron Systems is available here.