One of the most interesting and, to me, most complicated fields of 3D printing research is that of 3D-printed reactionware. As someone who has only in my adult life learned to appreciate chemistry, the possibilities of 3D-printed mechanisms for controlling chemical reactions are hard to comprehend. Lee Cronin has probably attracted the most amount of attention on the subject, after 3D printing compartments for chemical catalysts on his lab’s Fab@Home 3D printers. The idea is that, one can possibly 3D print a structure, injected with different chemicals, that, when a slot is opened here or a piece is turned there, the chemicals react to form a desired compound. More recently, Scientists Xiaolong Wang, at the Chinese Academy of Sciences in Lanzhou, China, and Jun Yang, of the University of Western Ontario in Canada, have explored methods for applying post-processing chemicals to change the surface properties of a 3D-print.

The researchers mixed bromine-containing acrylate to a UV-curable resin for 3D printing. After printing structures from the material, the objects were selectively coated with a reactive chemical, 3-sulfopropyl methacrylate potassium salt (SPMA), using a technique called atom transfer radical polymerization (ATRP). A reaction between the chemical and the acrylate caused the growth of polymer brushes onto the surface of the material. Depending on the application, these polymer brushes can be used to apply a variety of properties to a given object.

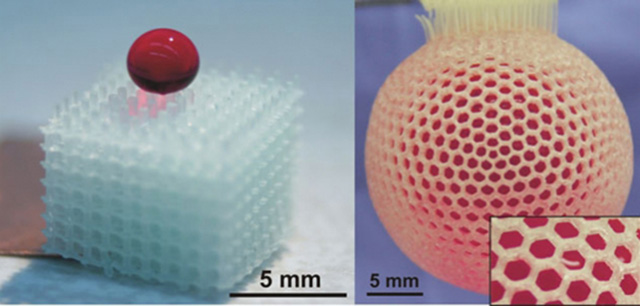

Wang, et al. tested the procedure with two different structures, a cube made up of lattices and a hollow, mesh ball. After initiating the growth of SPMA brushes using the ATRP procedure, the two structures took on superhydrophobic or superhydrophilic, water repelling or water retaining, characteristics. In the figures above, the SPMA prevented a droplet from entering the lattice cube and prevented liquid from leaving the mesh ball. The video below demonstrates that, even when the ball, with a 2.5 cm diameter and 1 mm pores, is shaken, the liquid is retained inside.

Such a process would make it possible to construct objects of any given shape that maintain specific chemical properties. For instance, items could be printed that contain chemical gateways, allowing some chemicals to permeate the surface, while blocking out others. This could have implications for the field of medicine, allowing for the development of biomedical components that resist bacteria or other unwanted environmental hazards. And, as a non-scientists, I’m thinking you could make some nice water-resistant shoes with it too.

Source: ChemComm