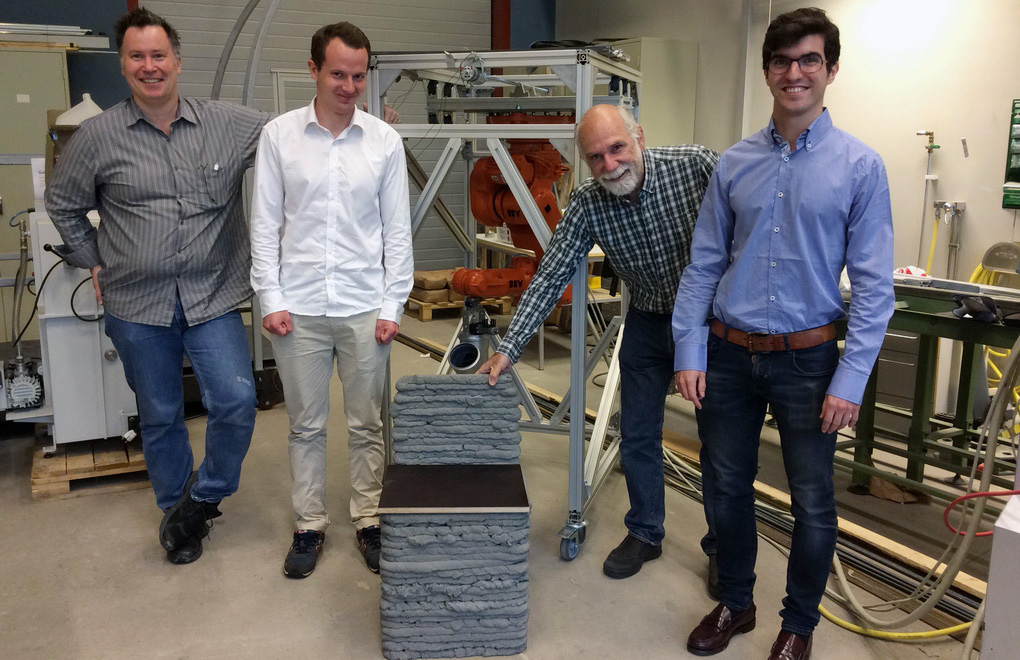

While Prof. Olaf Diegel is now known as the father of 3D printed instruments, with his complete ensemble of guitars, keyboard, and drums performing regularly at expos worldwide. Diegel, however, is not limited to instruments, as evidenced by an open source robot he designed last year. In fact, the father of 3D printed instruments is also a professor at the University of Lund, where his experiments with 3D printing are becoming bigger and more elaborate, as he and his colleagues have begun building a mobile concrete 3D printer.

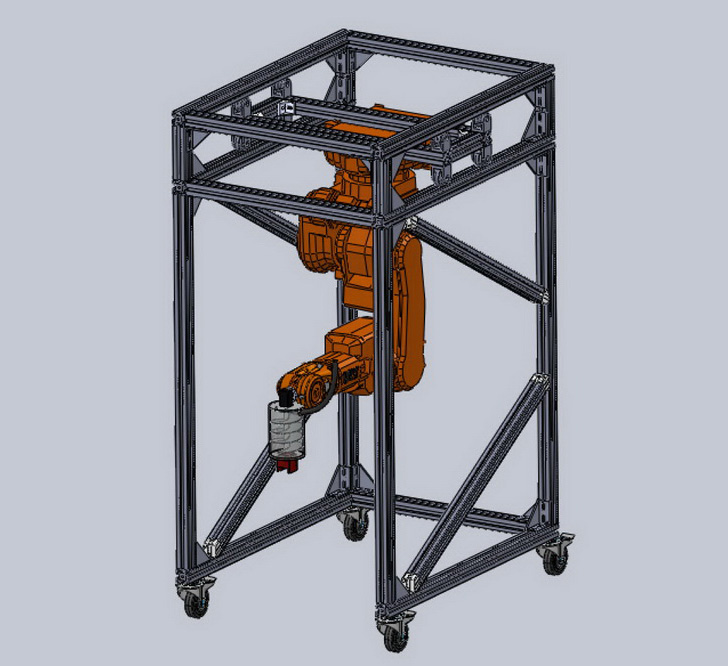

Prof. Diegel explains on the ODD Guitars website, “This project began through a conversation with Helsingborg Hem, the Helsingborg city department responsible for providing housing to its citizens, who were interested in working with Lund University on developing a demo 3D printer machine to print houses.” He continues, “However, as with many projects undertaken without a budget, the Additive Manufacturing research team at Lund University had access to a spare ABB robot arm, so they decided to start with a smaller scale proof-of-concept system that was capable of printing street furniture, or public artworks.”

In this way, the concrete 3D printer could be moved around from one place to another, Prof. Diegel says. “The idea was for a 3D printer that could be quickly wheeled into position, locked down, print a concrete bench, for example, and then be moved to the next spot to print the next object.”

While the project was overseen by Prof. Diegel and relied on some of his technology, much of the work was carried about by two Masters students, Borja Serra and Lars Henrik Anell, who set about converting the ABB IRB140 robotic arm into a mobile 3D printer. Serra took responsibility for designing the frame, software, and programming of the printer, while Anell handled the design and construction of the printhead itself.

Serra constructed a frame from standard aluminum extrusions, with a removable component ensuring that the frame keeps its shape during transport, but that can be taken out when on location so that the robot has a greater reach. The robot relies on MATLAB to slice an STL file and, instead of translating it to gCode, converts it to RAPID code, the language used by the robotic arm. A separate algorithm is responsible for controlling the flow of concrete and maintaining a continuous flow.

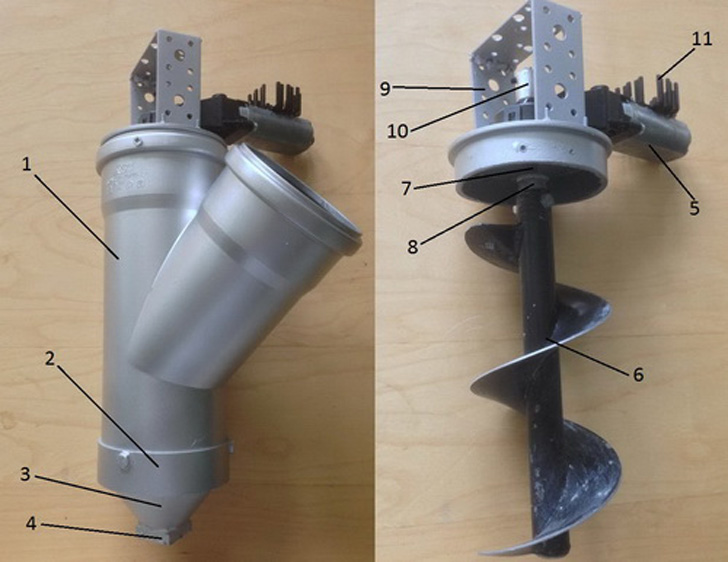

For the printhead, Anell blew up a desktop extruder design of Prof. Diegel’s, meant to extrude polymer from granules. To do so, Anell used a 100mm hole boring auger to send concrete to the printer nozzle.

This is just the first proof-of-concept for the project, with the video above representing the printer before the concrete feeder was added to the machine. In the future, the team hopes to add paddles to the printer in order to smooth objects as their printed. They’re also considering replacing the arm with a gantry system for larger prints. Hopefully, we’ll see this project evolve into something even bigger in the near future! A concrete guitar, I’m not so sure.