While researchers like Hod Lipson are working on advanced multimaterial 3D printing techniques behind institutional doors, Harvard’s Jennifer Lewis is advancing 3D printing technologies on both the commercial and the academic fronts. The material scientist’s Voxel8, of which she is the CEO, has already launched its first multimaterial 3D printer with plans to integrate new materials into its platform in the future. Meanwhile, she continues to perform her research, with the latest dealing directly with multimaterial 3D printing, this time with viscoelastic materials.

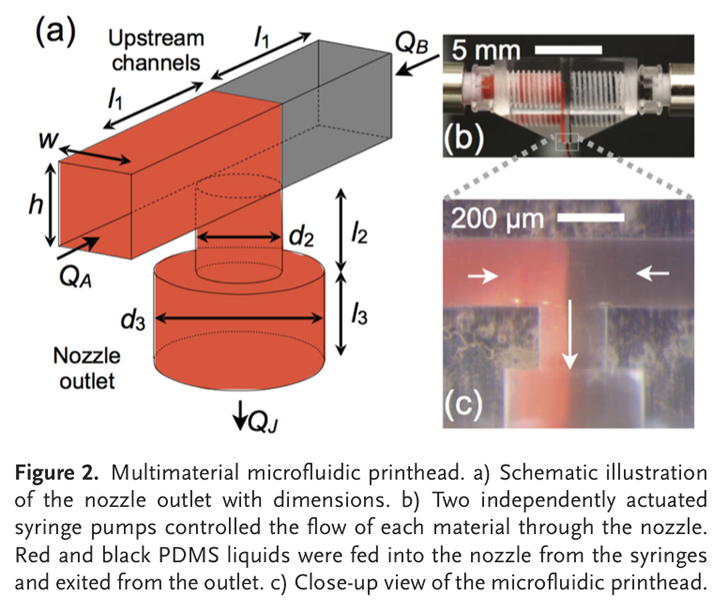

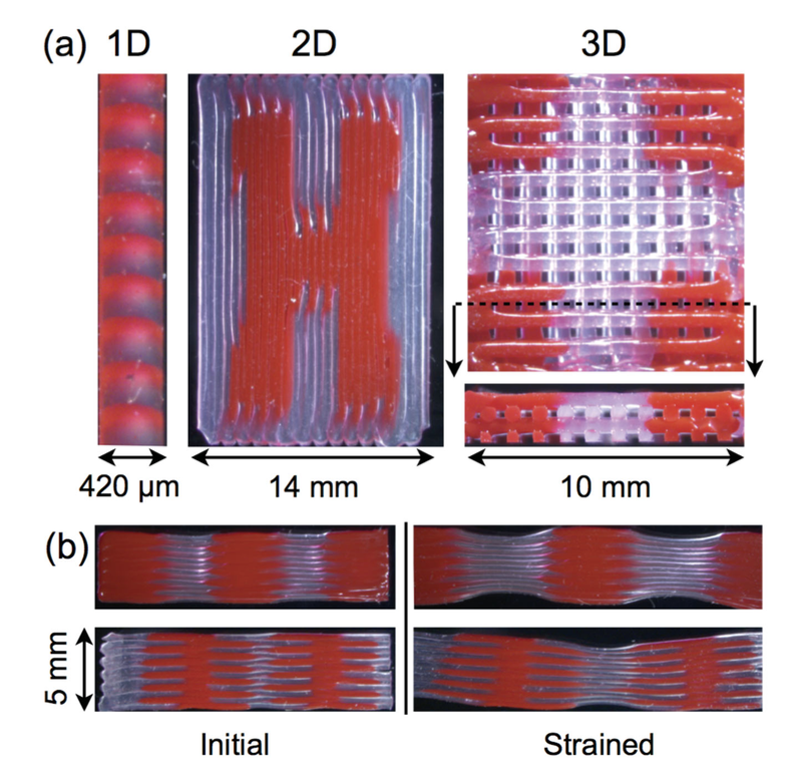

In a paper published in Advanced Materials, titled “Microfluidic Printheads for Multimaterial 3D Printing of Viscoelastic Inks”, Dr. Lewis and her team outline a process by which they 3D printed two types of viscoelastic inks, those that are both viscous and elastic, from a single nozzle on the fly. Specifically, the researchers created a custom, dual-chambered printhead that separates two different materials, connected to their own syringe pumps. While printing, the printhead has the ability to shut off one pump and switch on the other, allowing the material flow to switch immediately.

By using one nozzle, there’s no need to cause multiple printheads to work in unison. And, because the process described requires no heating, but instead rely on a syringe pump system, a broad range of materials can be utilized in the 3D printing process. With this technique, then, the authors of the paper explain that there lays the possibility of printing with “viscoelastic inks composed of myriad materials, including ceramic particles, metal particles, polyelectro- lytes, hydrogels, filled epoxy resins, and even cell-laden extracellular matrices. To date, this extrusion-based printing method has been used to fabricate functional devices (e.g., 3D antennas, rechargeable microbatteries, wearable sensors, structural composites, and vascularized 3D tissue.”

The ability to 3D print antennae, specifically, would aid Dr. Lewis’s Voxel8 in its venture with a government sponsor to 3D print complete antenna arrays. When such a printhead might be integrated into the Voxel8 platform remains to be seen, but it’s likely that their printer will incorporate the materials research developed by Dr. Lewis in the future.