I first encountered 3D Hubs at the SXSW Create Expo, where they had a booth promoting their distributed network of local printers. Using the site’s database of 3D printer owners, an individual can upload an .STL file to the site, select the closest printer, and have their object printed to be picked up from the printer owner’s location or delivered directly to their doorstep.

Located next to the entrance of SXSW Create, the 3D Hubs booth had a decent crowd of people intrigued by the collection of 3D printed versions of the site’s logo. I was examining the booth, when one of the representatives approached me and asked if I wanted to be 3D scanned. Apparently, one of the activities of this particular booth was scanning passersby. I said “yes” and stepped behind the booth, where the rep circled around me with a handheld scanner. The first scan didn’t work out as well as they liked, so they circled around again.

The second scan turned out quite well, with impressive detail, especially in capturing the intricacies of my French-braided hair. They showed me the scan on the screen, rotating the form to highlight the details. The scan looked good, but would still need some finishing touches to make it into a printable file. I was told that the file would be cleaned and then emailed to me. The 3D Hub team offered me a coupon for a free print on their network, so I gave them my email address and continued on with my SXSW adventures.

A couple of weeks later, I got an email with the file and, after uploading the file to 3D Hubs, I entered my location and was presented with a list of available printers in my area, organized by location. Navigating the search for particular details (location, printer type, shipping options) was quite simple. With different printers and printing materials to choose from, prices are immediately calculated based on the size of the figure and the printing materials selected. I selected a printer in the South Austin Area, a hub called 3Degrees Askew, run by a man named Taylor Stull. And, after finishing the process, got an email that said that my print would be ready in just a couple of days.

When that day came, about forty-eight hours later, I drove out to the printer location, the suburban town of Kyle, just south of Austin. Upon arrival, it was obvious that 3Degrees Askew is sort of a geek wonderland. The workshop is a room slightly larger than the average garage, with an alcove occupied by a row of a half-dozen printers. At the end of the row stood a Frankenstein-style machine, made from the best parts of various other printers.

Stull kindly shows me around the various workspaces: Every table surface is covered in materials and tools. There a small area where he is working on scanning a clay rhinoceros. There is a large table covered in a wider variety of finished projects.

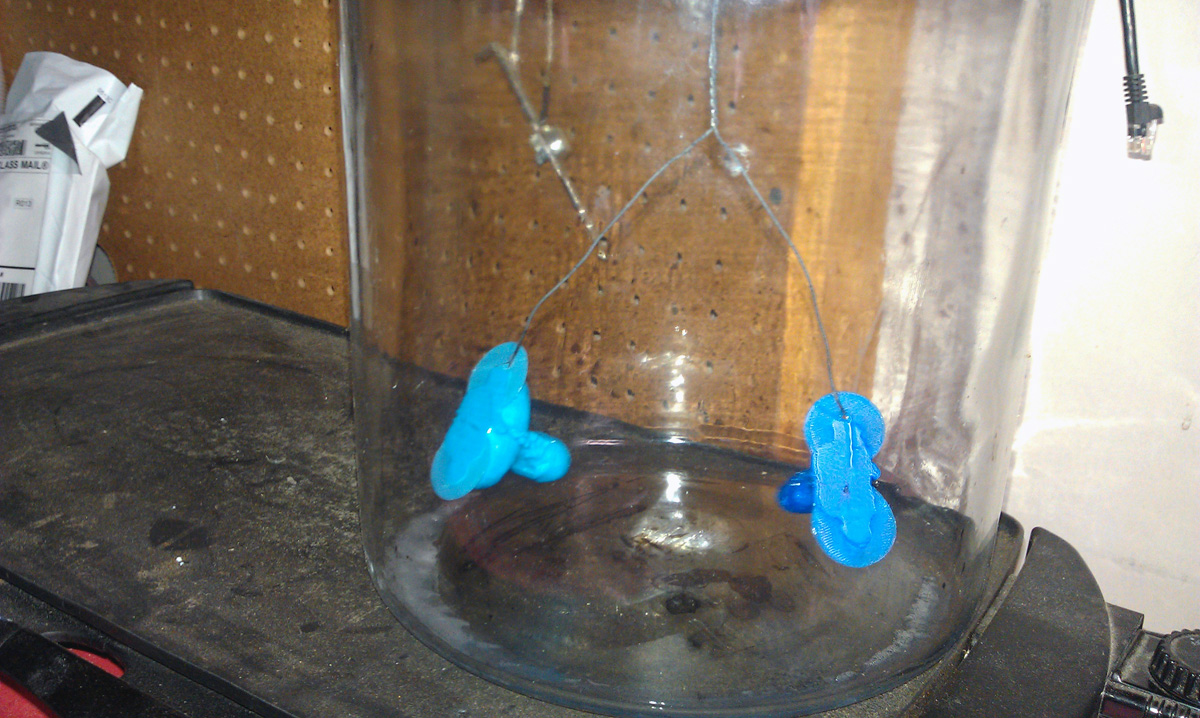

Stull shows the finished versions of the scans that I had ordered. They were printed in high-resolution ABS and the results were quite impressive and the Maker intends to polish off two of the prints with an acetone bath. So, we head to another section of the workshop, where Stull has a large glass jar with acetone on a heated bed. He turns the heat on and we wait for the acetone to reach the appropriate temperature. The suspense. The suspense.

When the acetone is heated, Stull puts the prints on wires that are suspended in the jar. The technique is a bit like roasting marshmallows and the prints are adjusted as they are affected by the acetone. The results quite impressive. The (shiny) prints on the far left and right are those treated with acetone.

I decide to ask Taylor some questions about how he ended up ruling this particular domain – for instance, how he launched the 3Degrees Askew printing space. Stull replied, “I just got into 3D printing by buying a printer and I just liked it so much that I’m now doing it full time. I got a Makerbot, and the thing is, it took two months for my Makerbot to show up and, in that 2 months, I learned all about 3D printing. I had ordered the second Makerbot and two other printers by the time I just started and I’m full into it now.”

And, about joining the 3D Hubs network in particular, Stull explained, “I was just browsing and I just signed up for them. I was one of the first sign-ups on 3D hubs and I was on there about five months before I got a job. They were all based in the Netherlands. They have to have a certain amount of printers in a hub area before they even send you jobs. I was on there five months before there were enough printers signed up in Austin. I kind of dominate it now.”

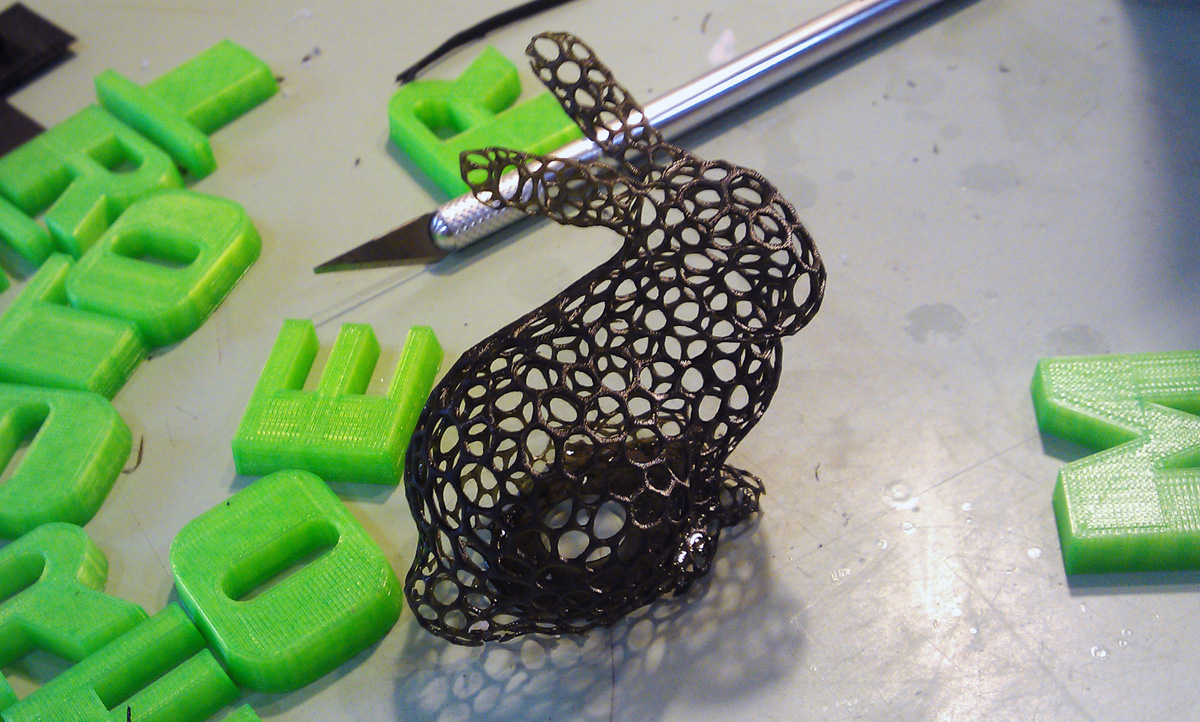

Out of the wide range of printers he owned, the Maker highlighted the Titan 1 DLP 3D printer, which was funded on Kickstarter last year in just two minutes. When I asked why the Titan 1 was his favorite, he told me, “The speed and the quality. It’s not the FDM, which is fused deposition modeling. It’s the resin printer, which uses light cured resin. It prints in super high quality. They call it ‘ultra resolution’.” Showing me a 3D printed rabbit, he explains, “You just can’t print that kind of detail on a filament deposition. So it’s my favorite.”

I was specifically interested in the oddities that Stull had come across, asking him if he’d had any particularly strange prints. Taylor replied, “See, that’s the thing: being in the business, you never know what’s gonna come through the door… I have a big project. I’m printing horseshoes. This guy, he has a patent for a hinged horseshoe where the back of the shoes will flex in and out a bit. So, now were going into business a bit. See, I’m gonna print him horseshoes.”

Overall, I had a very positive 3D Hubs experience and could see this sort of endeavor being very useful to a 3D printing enthusiast. The process provides an excellent way to test qualities of different printers and materials, without investing heavily. At the same time, it access to the expertise of a person already familiar with the printing process. Leaving 3Degrees Askew with my prints in hand, I thought that, not only would I recommend the 3D Hubs network, overall, but would send those in the Austin area Taylor’s way, too.