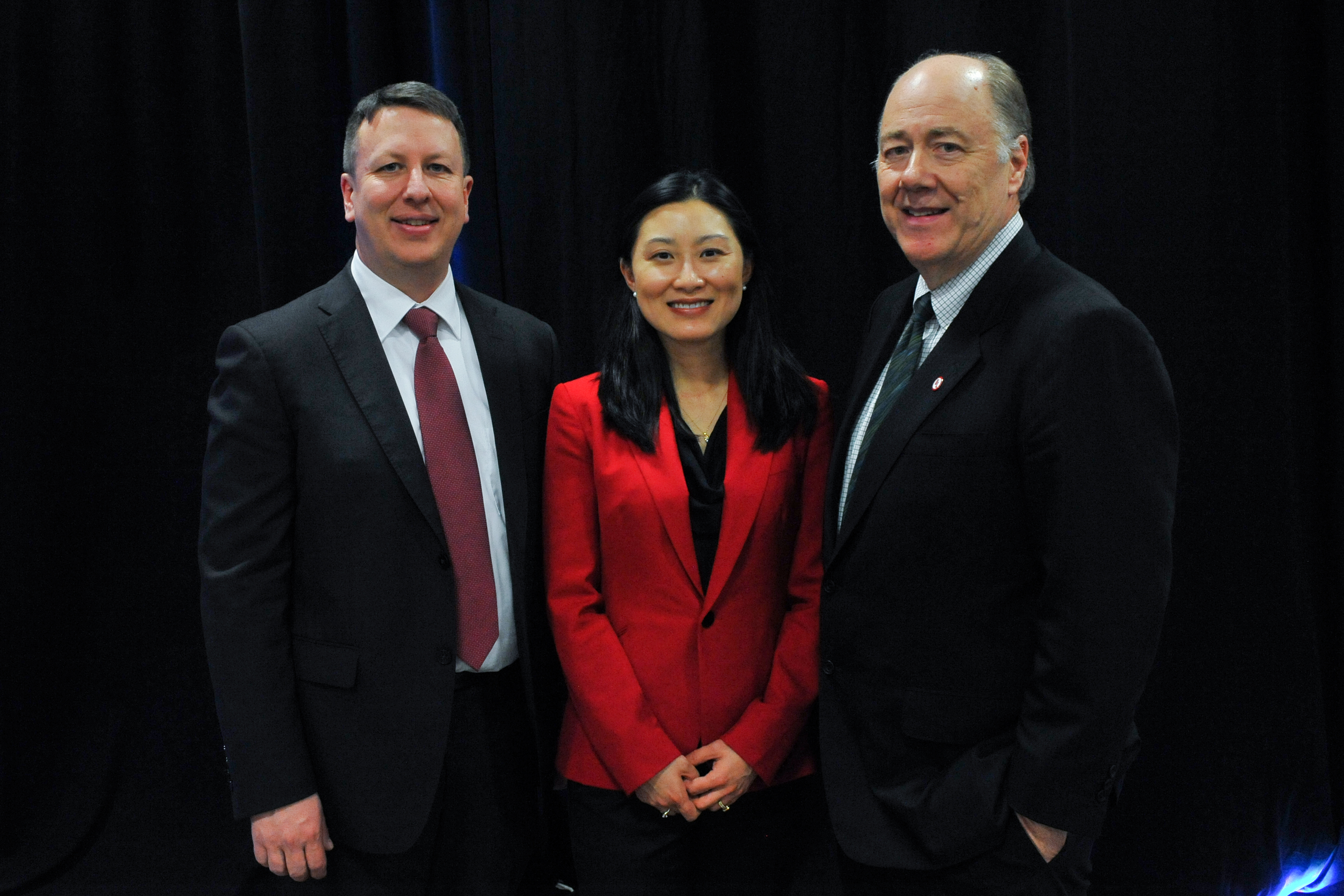

2015 is about mergers, acquisitions, and new 3D printing materials. As we head towards 2016, we can expect the rate of new and unexpected partnerships to increase. For example, UL and 3DSIM LLC made an interesting announcement about an agreement to advance 3D printing process simulations. The terms of the agreement show that UL invested in 3DSIM and is now a minority shareholder of the company. Simin Zhou, vice president of Digital Manufacturing Technologies at UL, will be joining the 3DSIM Board of Directors as a result of the agreement and companies mutual mission to serve manufacturers.

Zhou said of the agreement, “UL has partnered with 3DSIM to rapidly advance simulation for additive manufacturing processing. The value of 3D printing is to enable design freedom and the ability to manufacture a variety of parts and products. To statistically qualify a design for production using AM, exploring material and process combinations via trial-and-error is not sustainable. Thus, we must invest in simulation technology and new qualification and validation methodologies to advance manufacturing and move the AM industry forward.”

Brent Stucker, PhD., chief executive officer and a co-founder of 3DSIM LLC, said, “UL has an excellent reputation around the world in validation and certification of manufactured parts. We welcome UL as an investor and partner. As a member of our board, Simin will contribute her deep knowledge and perspectives about how simulations can transform the AM industry. Together, we will move the manufacturing industry away from reliance upon costly experimental testing toward predictable, safe and timely production.”

So who is 3DSIM exactly?

3DSIM is a growing company that produces specialized software tools that enable accurate, physics-based analyses and predictions of 3D printing processes, before building or fabricating a component. According to the company, their simulation tools are designed to help “users, part designers, researchers, machine manufacturers and material providers dramatically increase their rate of innovation, thus enabling rapid qualification of additively manufactured parts and components.” The start-up, which hopes to bring much needed quality assurance to industrial 3D printing, has already begun working with Additive Industries to release the first metal 3D printer that will use 3DSIM’s print preview technology.

UL industries has a proven track record (120 years) in safety science, and have recently begun merging their operations with the booming 3D printing industry. With their expertise in standards, compliance, testing, certification, manufacturing processes and engineering, they have been making some interesting moves lately that indicate a clear directive to educate and train interesting individuals as well as standardize compliance and confer with regulators about industry issues. This new investment adds one more intriguing element to UL’s growing role in 3D printing.