The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

Industrial 3D printer manufacturer Stratasys has developed a new data security platform designed to enhance the cybersecurity of 3D printing for US government and mission-critical defense applications.

Called ProtectAM, the security offering integrates Red Hat Enterprise Linux, one of the world’s leading enterprise platforms which meets the US Government’s strict requirements for continuous information processing.

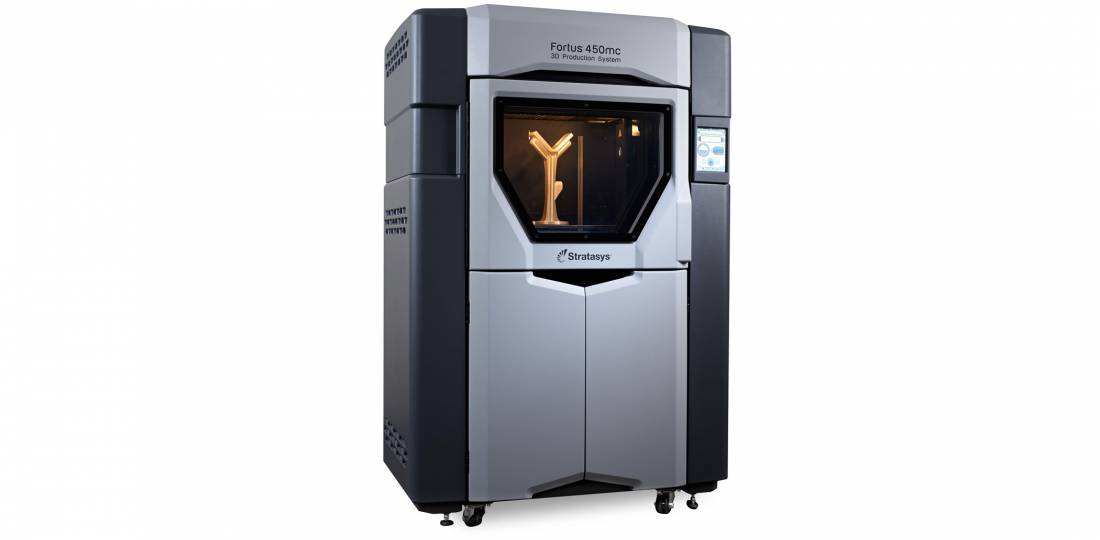

Initially, ProtectAM is available for Stratasys’ industrial large-format Fortus 450mc 3D printers, and will be rolled out to its F900 3D printers by the end of the year. Eventually, the firm plans to extend the security platform to all printers that use its technologies, and to industry sectors beyond government.

“The benefits of 3D printing are clear, including getting critical products wherever they are needed, with maximum speed and minimal cost, all while extending the lifespan of existing assets to save taxpayer dollars,” said Dick Anderson, Senior Vice President for Manufacturing at Stratasys.

“Furthermore, the integrity of parts printed from digital files is absolutely essential, and we have established the ProtectAM solution to be a world-class security solution to continue the adoption of additive manufacturing by government agencies, and ultimately to commercial segments as well.”

Stratasys and 3D printing for defense

The US Department of Defense (DoD) unveiled its first official additive manufacturing strategy earlier this year, drafted alongside other US military services and defense agencies. The strategy will seek to establish a common vision for the use of 3D printing within the nation’s defense program, outlining five strategic goals to broaden the adoption of the technology and its applications.

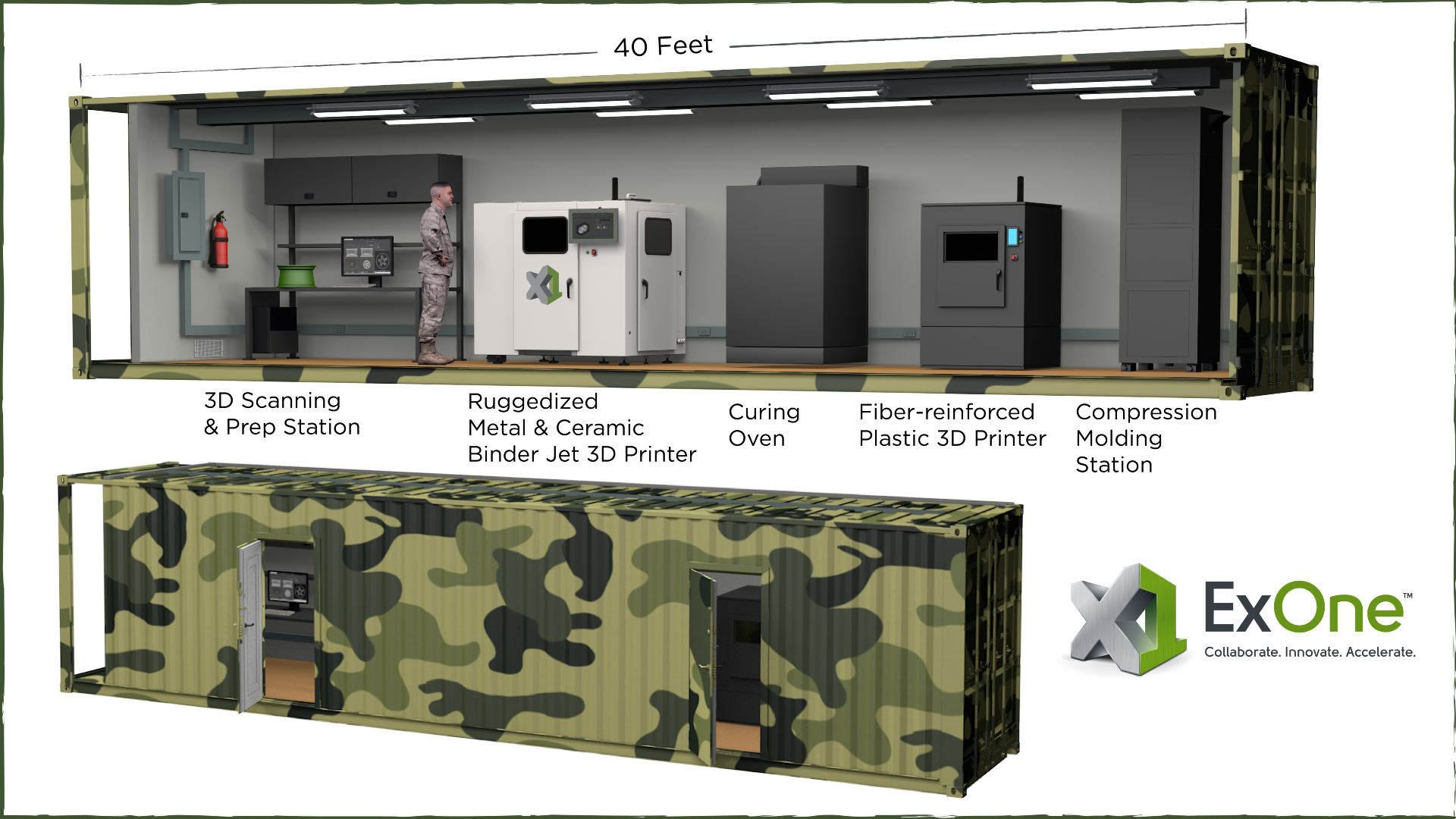

Since announcing the strategy, the DoD has tasked binder jet 3D printer OEM ExOne to develop a portable 3D printing factory capable of producing spare parts in the field, and has provided funding to additive manufacturing data specialist Senvol to enhance its machine learning software for the qualification of 3D printing materials and processes for defense applications.

Earlier this month, the US Navy awarded Stratasys a $20 million contract that will see the firm supply the Navy with up to 25 F900 3D printers over the next five years, in addition to the materials, support and training needed to run them. The deal aims to shorten the US Military’s supply chains while providing the Navy with enhanced aircraft repair capabilities.

Off the back of this, Stratasys has been working on a data information security offering that improves the cybersecurity of 3D printing as its adoption for government and defense applications grows and becomes more mission-critical.

The ProtectAM data security platform

Stratasys’ ProtectAM platform has been design to help safeguard sensitive information across the DoD’s network of 3D printers that are being deployed for distributed additive manufacturing. The security offering is reportedly the first in 3D printing that uses the Red Hat Enterprise Linux enterprise platform.

Red Hat Enterprise Linux is the preferred security platform by the US Government for continuous information processing security. The platform meets the requirements of the DoD’s Defense Information System Agency’s (DISA) Security Technical Implementation Guide (STIG).

The STIG outlines several hundred security controls to protect against cybersecurity threats, and by implementing the Red Hat Enterprise Linux platform, Stratasys’ ProtectAM is compliant with these requirements.

“Software security if a front-and-center challenge for nearly every government agency, and a need that Red Hat helps to address through our extensive work in certifying the world’s leading enterprise Linux platform to meet stringent public security requirements,” said David Egts, Chief Technologist, North America Public Sector, Red Hat. “Red Hat Enterprise Linux provides a platform that assists users in meeting the rigorous software security needs for sensitive computing without sacrificing flexibility, scalability or innovation.

“We’re pleased to be able to provide this as a foundation for Stratasys as they work to innovate industrial 3D printing and additive manufacturing in the public sector.”

The ProtectAM system will open up Stratasys’ machines to new applications within defense that extend beyond R&D settings. Adhering to the DoD’s STIG security controls, the systems will be more readily deployable to form distributed networks of 3D printers across the US Military’s bases and within the field.

Built on the Federal Information Processing Standards (FIPS) and Common Criteria government-certified foundation of Red Hat Enterprise Linux, Stratasys’ technology will facilitate the secure sending of mission-critical digital files wherever they are needed, enabling parts to be 3D printed quickly and locally at the point of need.

ProtectAM will be made initially available for several of Stratasys’ FDM 3D printers which are currently used by customers of the US Government to produce end-use parts and tools within the aerospace sector. From today, the security platform will be made available on the Fortus 450mc, and will be available on the firm’s F900 3D printers by the end of the year.

Looking ahead to next year, Stratasys plans to roll out ProtectAM to its F370 and F770 machines in Q1, followed by printers that use the company’s other technologies later down the line.

Eventually, Stratasys is aiming to extend the cybersecurity benefits of the ProtectAM platform to industry segments beyond government and defense.

Data security in defense AM

After announcing its additive manufacturing strategy, the DoD came under scrutiny for its plans to roll out 3D printing across the nation’s military. Concerns raised by an independent watchdog claimed the technology creates “unnecessary cybersecurity risks” and the DoD’s 3D printers could be made vulnerable to sabotage.

The main cybersecurity risks in 3D printing typically center around IP theft and process sabotage. For instance, cloud-based file-sharing systems may be hacked, email servers can be breached, and solid 3D printed parts could potentially be reverse-engineered using 3D scanning technology. As shown by the launch of Stratasys’ ProtectAM platform, the DoD does appear to be working with industry players to address these concerns.

Additionally, the development of methods and processes to improve cybersecurity within 3D printing is continually increasing, with technologies such as blockchain being harnessed to secure the digital thread of 3D printing processes. In fact, the US Air Force has previously investigated how blockchain can be used to register and track 3D printed components with SIMBA Chain, as part of its Blockchain Approach for Supply Chain Additive Manufacturing Parts (BASECAMP) project.

Elsewhere, the UK’s Ministry of Defence (MOD) is trialing a new patented technology from DEFEND3D that aims to protect against cybercrime and IP theft during remote 3D printing. Rather than sending 3D files, the technology allows a digital asset to be live-streamed to a 3D printer in real-time to provide only the vital information for printing before instantly deleting it.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Stratasys has announced a new ProtectAM cybersecurity solution for additive manufacturing to meet the demanding requirements of U.S. government implementations. Photo via Stratasys.