The U.S. Department of Defense (DoD) has announced plans to roll out 3D printing across the country’s military despite concerns raised by an independent watchdog that the technology creates “unnecessary cybersecurity risks.”

With its first official 3D printing policy, the DoD has formally laid out how it intends to scale the technology’s deployment across the U.S. Armed Forces. However, these plans are under increased scrutiny after a recent report issued by the DoD Inspector General, a Presidentially-appointed auditor, who claims that the DoD’s 3D printers have access to its wider Information Network, making them vulnerable to sabotage by hostile actors.

When contacted by 3D Printing Industry regarding the Inspector General’s concerns, NCDMM and America Makes’ VP and CIO Joe Veranese suggested that the security issues raised can be rectified by technological rather than regulatory means.

“It is not a question of whether or not to connect a machine to a network due to potential vulnerabilities, but how to do it to ensure a secure connection,” explained Veranese. “There are many innovative and secure ways to connect machines to a network to fully leverage the digital nature of advanced manufacturing.”

Is AM a “cybersecurity risk?”

Broadly speaking, an Inspector General is a public official responsible for overseeing the operation of government agencies, ensuring that they’re run as efficiently and fairly as possible. With regards to the DoD’s watchdog specifically, their role includes reviewing proposed legislation and promoting policies that prevent abuse within defense operations, thus the DoD’s 3D printing strategy falls well within their remit.

The Inspector General’s main bone of contention with the policy, lies in the categorization of 3D printers as “standalone systems,” instead of connected ones needing cybersecurity. Among the proposals made in the watchdog’s report, they call for this to be rectified, and for the DoD to provide guidance on which regulation applies to 3D printing, to “reduce the risk of continued non-compliance.”

The DoD Inspector General has also suggested that an Authorization to Operate (ATO) be required for military 3D printing, and for its part, the U.S. Air Force has agreed to implement this by 2022. However, the ombudsman’s wider advice appears to have fallen on deaf ears, as the momentum of the DoD’s 3D printing roll-out shows no sign of slowing down.

In a further escalation of tensions, the Inspector General recently raised new security concerns in a redacted audit, in which they alleged that five DoD sites failed to secure their systems appropriately. In fact, given the time taken to update them, many of the 3D printers at these bases were found to be running old software, meaning that they could’ve been at risk of tampering by subversive forces.

“The compromise of additive manufacturing (AM) design data could allow an adversary to re-create and use DoD technology to the adversary’s advantage on the battlefield,” explained the DoD Inspector General in their report. “In addition, if malicious actors change the AM design data, the changes could affect the end strength and utility of the 3D printed products.”

The DoD’s divisive policy

The Inspector General’s findings follow the launch of the DoD’s first official 3D printing policy, as well as its wider additive manufacturing strategy, in which it has committed to further adopting the technology. In particular, the DoD’s policy highlights 3D printing’s potential for reinforcing supply chains, “increasing logistic resiliency and improving self-sustainment” across the U.S. Military.

The DoD guidelines also underline the importance of private sector participation, and suggest that working with small firms could “advance its weapon systems capabilities,” while adding that proper training, engagement, and operational alignment will be needed to ensure the technology can be rolled-out smoothly.

With this in mind, the DoD document includes guidance on who’s responsible for policing the technology’s deployment, with the Under Secretary of Defense for Research and Engineering named as being accountable for monitoring 3D printing policy, in addition to “developing and maintaining AM cybersecurity test and evaluation policy and guidance.”

Elsewhere, the guidance also makes reference to the need for “mission-based cyber risk assessments” to prevent security breaches, but critically there’s no mention of curbing 3D printing’s roll-out in the process. By contrast, the Defense Logistics Agency’s online file sharing platform, the “Joint AM Model Exchange,” seems to epitomize the very approach the Inspector General has warned against.

In support of the ‘JAMMEX’ 3D model catalog, America Makes’ Veranese added that it prevents each DoD directorate from having to “reinvent the wheel” when sharing models by creating a secure part database, while its sophisticated firewall only grants access to CAC users based on strict profile requirements.

Moving forwards, despite ongoing claims by its Inspector General that the “DoD doesn’t consistently secure or manage its AM systems,” the DoD is reportedly aiming to advance rather than amend its new policy, with a Joint AM Working Group led by its own Tracy Frost set to oversee this from the Pentagon.

Military 3D printing in-action

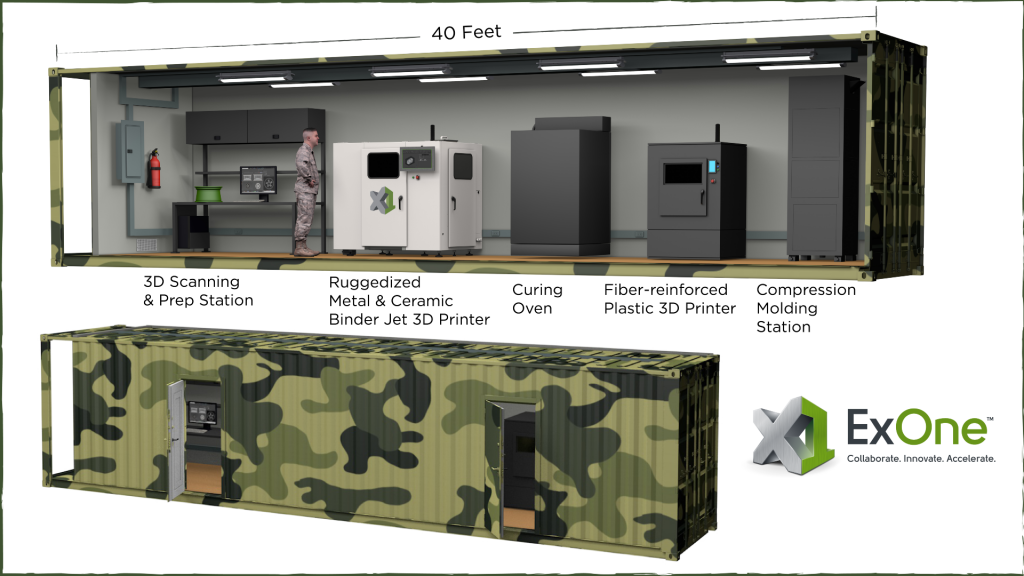

The Inspector General’s warnings come at a time when the DoD seems more intent than ever to harness 3D printing’s insourcing potential. Earlier this year, binder jet 3D printer OEM ExOne was contracted by the Defense Logistics Agency to build a ‘mobile 3D printing factory,’ which can be rapidly deployed by soldiers to create spare parts in the field.

The U.S. Navy has also turned to AM in order to better secure its supply chains, by installing Xerox’s ElemX Liquid Metal 3D printer at its Naval Postgraduate School (NPS). Through the recently-established research collaboration, engineers from both parties aim to identify a new means of optimizing the way in which the military supplies deployed forces.

In the past, the researchers from Wichita State University have even worked with the U.S. Army to create an entire digital twin of a Black Hawk helicopter. By stripping down, scanning, and cataloging the aircraft’s parts, the project’s engineers sought to assess 3D printing’s potential for reinforcing military supply chains and sourcing discontinued parts.

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an M1 Abrams tank under TACOM. Photo via U.S. Army.